Hybrid relays combine the fast switching capabilities of solid-state components with the high current capacity of electromechanical contacts, reducing wear and improving reliability. Understanding the key differences between hybrid relays and traditional contactors can help you choose the best solution for your electrical applications--read on to explore their advantages and use cases.

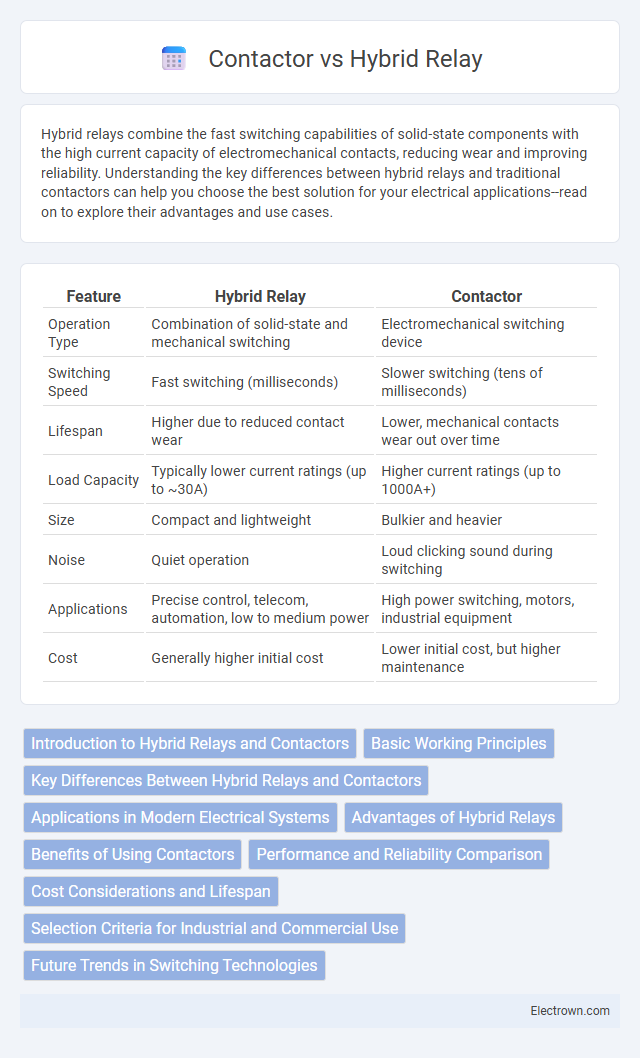

Table of Comparison

| Feature | Hybrid Relay | Contactor |

|---|---|---|

| Operation Type | Combination of solid-state and mechanical switching | Electromechanical switching device |

| Switching Speed | Fast switching (milliseconds) | Slower switching (tens of milliseconds) |

| Lifespan | Higher due to reduced contact wear | Lower, mechanical contacts wear out over time |

| Load Capacity | Typically lower current ratings (up to ~30A) | Higher current ratings (up to 1000A+) |

| Size | Compact and lightweight | Bulkier and heavier |

| Noise | Quiet operation | Loud clicking sound during switching |

| Applications | Precise control, telecom, automation, low to medium power | High power switching, motors, industrial equipment |

| Cost | Generally higher initial cost | Lower initial cost, but higher maintenance |

Introduction to Hybrid Relays and Contactors

Hybrid relays combine semiconductor switching elements with electromechanical components to deliver fast, reliable switching with reduced contact wear compared to traditional contactors. Contactors are electromagnetic switches designed for high current applications, providing robust mechanical switching but with slower operation and higher maintenance due to contact erosion. Understanding the differences between hybrid relays and contactors helps you select the optimal device for applications requiring efficiency, longevity, and precise control.

Basic Working Principles

Hybrid relays combine a solid-state switching element with a mechanical contact to achieve faster response times and longer life, utilizing semiconductor devices to handle low-power signals and mechanical contacts for high current loads. Contactors operate purely through electromagnetic coils that create a magnetic field to open or close high-current circuits, relying entirely on mechanical movement for switching. The integration of semiconductor components in hybrid relays enhances switching speed and reduces contact wear compared to traditional contactors, making them suitable for applications requiring frequent switching and precise control.

Key Differences Between Hybrid Relays and Contactors

Hybrid relays combine solid-state and electromechanical components, offering faster response times, lower power consumption, and longer operational life compared to traditional contactors that rely solely on mechanical contacts. Contactors are preferred for high current, heavy-duty applications due to their robust construction and higher current capacity, while hybrid relays excel in precision control and reduced electrical noise in medium to low power circuits. The key differences also include maintenance requirements, with hybrid relays requiring less frequent servicing and exhibiting lower contact wear, enhancing reliability in automation systems.

Applications in Modern Electrical Systems

Hybrid relays combine solid-state and electromagnetic technologies, offering faster switching and higher durability for applications in industrial automation, HVAC systems, and smart grids. Contactors excel in handling high-power loads such as motors, lighting, and heating equipment, making them ideal for heavy-duty electrical systems. Modern electrical systems leverage hybrid relays for energy-efficient control and contactors for robust load management.

Advantages of Hybrid Relays

Hybrid relays combine the fast switching speed of semiconductor devices with the high current capacity of electromechanical contacts, offering enhanced reliability and reduced electromagnetic interference compared to traditional contactors. Their compact size and low power consumption contribute to energy efficiency and space-saving designs in industrial automation systems. Hybrid relays also provide longer operational life and improved performance in harsh environments due to minimized contact wear and faster response times.

Benefits of Using Contactors

Contactors offer high reliability and robust switching capabilities for heavy electrical loads in industrial applications. They provide easy control for multiple circuits and can handle frequent switching without significant wear, enhancing operational efficiency. Additionally, contactors are cost-effective solutions with simple maintenance requirements, making them ideal for long-term use in power management systems.

Performance and Reliability Comparison

Hybrid relays combine solid-state and electromechanical components, offering faster switching times and enhanced durability compared to traditional contactors, which rely solely on mechanical contacts. The hybrid design reduces wear and arcing, resulting in longer operational life and increased reliability in demanding electrical applications. Contactor devices, while robust and widely used, have slower response times and require more maintenance due to contact degradation over time.

Cost Considerations and Lifespan

Hybrid relays typically offer a longer lifespan and lower maintenance costs than traditional contactors due to their solid-state switching combined with mechanical contacts, reducing wear and tear. Contactors generally have a lower upfront cost but often require more frequent replacement and servicing, increasing total cost of ownership over time. Your choice depends on balancing initial investment against durability and long-term reliability in your specific application.

Selection Criteria for Industrial and Commercial Use

When selecting between a hybrid relay and a contactor for industrial and commercial use, factors such as switching speed, durability, load capacity, and energy efficiency are crucial. Hybrid relays offer faster switching and longer operational life with minimal wear due to solid-state components, making them ideal for frequent cycling or sensitive electronic loads. Contactors provide robust performance for high-current applications and are preferred for heavy inductive loads, but they have mechanical parts that may require more maintenance and have slower switching times.

Future Trends in Switching Technologies

Hybrid relays combine mechanical contacts with semiconductor components to enhance switching speed and durability, positioning them as a key innovation in future switching technologies. Contactor technology continues to evolve with improvements in materials and coil designs, but the trend favors hybrid relays for applications demanding higher efficiency and reduced maintenance. Integration of IoT and smart grid compatibility further drives the adoption of hybrid relay systems in modern electrical infrastructure.

Hybrid relay vs Contactor Infographic

electrown.com

electrown.com