BLDC motors offer efficient speed control and high reliability with a simpler sensor design, while PMSM motors provide smoother operation and higher torque density due to their sinusoidal back EMF. Explore the rest of this article to understand which motor best suits your application's performance demands.

Table of Comparison

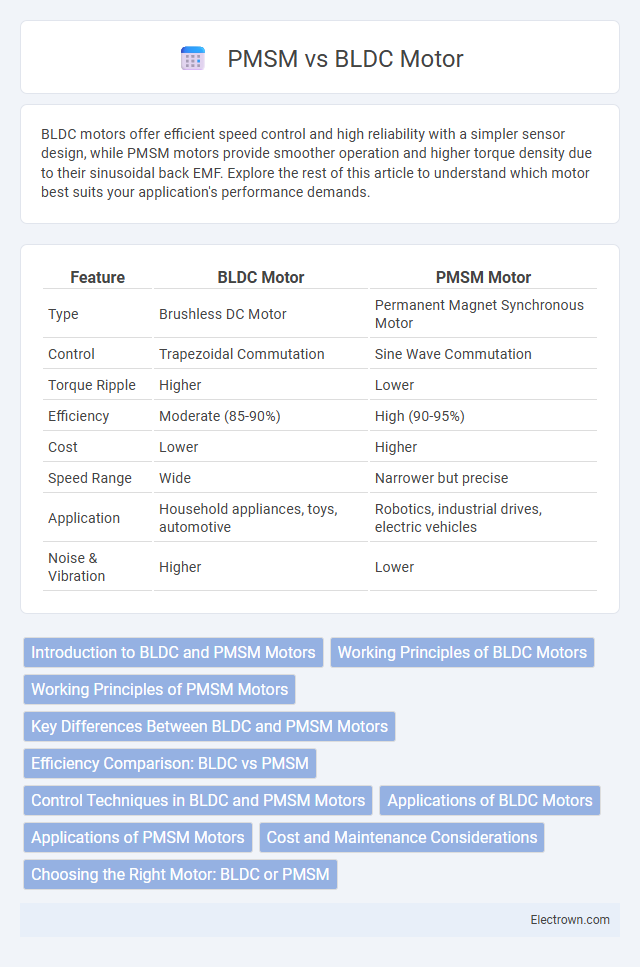

| Feature | BLDC Motor | PMSM Motor |

|---|---|---|

| Type | Brushless DC Motor | Permanent Magnet Synchronous Motor |

| Control | Trapezoidal Commutation | Sine Wave Commutation |

| Torque Ripple | Higher | Lower |

| Efficiency | Moderate (85-90%) | High (90-95%) |

| Cost | Lower | Higher |

| Speed Range | Wide | Narrower but precise |

| Application | Household appliances, toys, automotive | Robotics, industrial drives, electric vehicles |

| Noise & Vibration | Higher | Lower |

Introduction to BLDC and PMSM Motors

BLDC (Brushless DC) and PMSM (Permanent Magnet Synchronous Motor) motors are popular electric motor types known for high efficiency and reliability. BLDC motors use electronic commutation to control the rotor position, optimizing performance and reducing maintenance compared to brushed motors. PMSM motors feature constant magnetic fields from permanent magnets and synchronous operation, providing smooth torque and high power density ideal for precision applications.

Working Principles of BLDC Motors

BLDC (Brushless DC) motors operate using electronic commutation to switch current in the motor windings, creating a rotating magnetic field that interacts with permanent magnets on the rotor. Hall-effect sensors or sensorless back-EMF detection provide rotor position feedback to the controller for precise timing of current pulses. This mechanism eliminates the need for brushes, resulting in higher efficiency, reduced maintenance, and improved reliability compared to brushed DC motors.

Working Principles of PMSM Motors

PMSM motors operate using permanent magnets embedded in the rotor, producing a constant magnetic field that interacts with the stator's rotating magnetic field generated by three-phase AC currents. The rotor continuously aligns with the stator's magnetic field, resulting in smooth, precise, and efficient torque production. Your applications benefit from PMSM's superior efficiency and high power density compared to traditional BLDC motors.

Key Differences Between BLDC and PMSM Motors

BLDC motors feature trapezoidal back EMF and are controlled using six-step commutation, while PMSM motors have sinusoidal back EMF with smooth vector control for higher precision. BLDC motors typically offer lower cost and simpler control, making them suitable for applications requiring moderate performance. PMSM motors deliver higher efficiency, smoother torque, and better dynamic response, ideal for high-performance industrial and automotive applications.

Efficiency Comparison: BLDC vs PMSM

BLDC motors typically offer efficiency levels around 85-90%, benefiting from simpler construction and cost-effective manufacturing. PMSM motors achieve higher efficiency rates, often exceeding 90-95%, due to their sinusoidal back-EMF waveform and superior magnetic properties. The enhanced efficiency of PMSM motors leads to reduced energy losses and better performance in applications demanding precision and power density.

Control Techniques in BLDC and PMSM Motors

BLDC motors use trapezoidal commutation control with Hall sensors for rotor position feedback, enabling efficient and cost-effective operation. PMSM motors rely on sinusoidal commutation with Field-Oriented Control (FOC) or Vector Control techniques, providing precise torque control and smoother performance. Your choice between BLDC and PMSM control methods affects efficiency, noise levels, and overall system complexity.

Applications of BLDC Motors

BLDC motors are widely used in applications requiring high efficiency and reliability, such as electric vehicles, computer cooling fans, and drones. Their brushless design ensures low maintenance and long operational life, making them ideal for industrial automation and HVAC systems. The precise speed control and high torque-to-weight ratio further enable their integration into robotics and medical devices.

Applications of PMSM Motors

PMSM motors are widely used in electric vehicles, robotics, and industrial automation due to their high efficiency, precise control, and excellent torque density. Their ability to maintain consistent performance at varying speeds makes them ideal for renewable energy systems like wind turbines and HVAC applications. You will find PMSM motors preferred in applications requiring smooth operation and long service life.

Cost and Maintenance Considerations

BLDC motors generally have lower upfront costs due to simpler rotor construction without permanent magnets, making them more economical for budget-sensitive applications. PMSM motors, equipped with high-performance rare-earth magnets, offer higher efficiency and power density but incur greater initial investment and potential replacement expenses for magnet-related wear. You should weigh maintenance frequency and long-term operational savings against the initial cost to determine the optimal motor choice for your application.

Choosing the Right Motor: BLDC or PMSM

Choosing between BLDC and PMSM motors depends on application requirements such as efficiency, control precision, and cost. PMSM motors offer higher efficiency and smoother torque due to sinusoidal back EMF, making them ideal for high-performance applications like electric vehicles. BLDC motors provide simpler control and cost-effectiveness, suited for applications requiring robustness and lower complexity.

BLDC vs PMSM motor Infographic

electrown.com

electrown.com