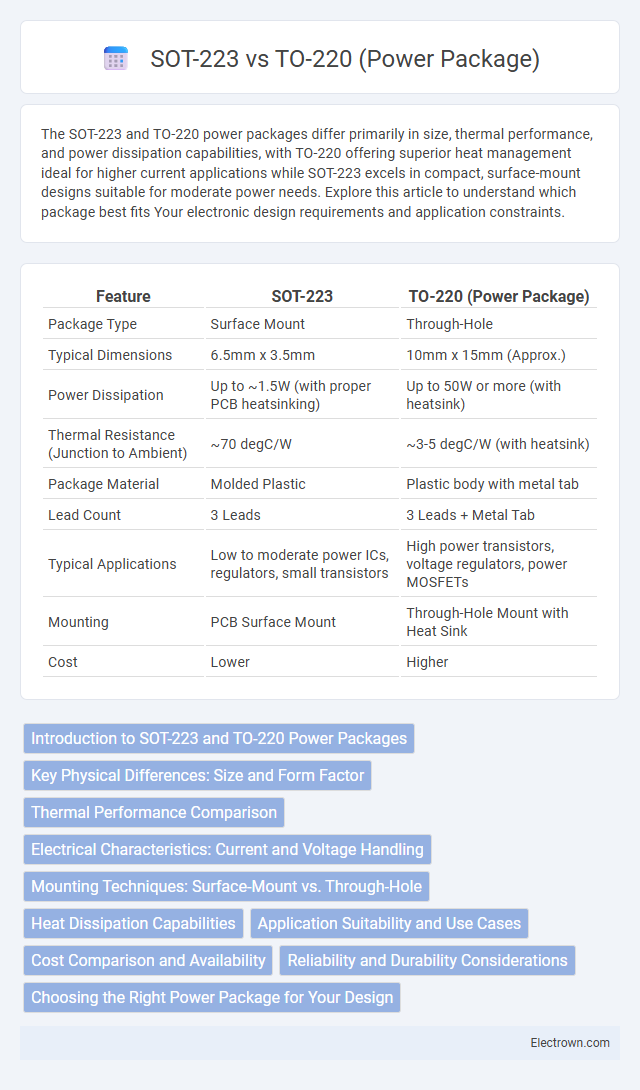

The SOT-223 and TO-220 power packages differ primarily in size, thermal performance, and power dissipation capabilities, with TO-220 offering superior heat management ideal for higher current applications while SOT-223 excels in compact, surface-mount designs suitable for moderate power needs. Explore this article to understand which package best fits Your electronic design requirements and application constraints.

Table of Comparison

| Feature | SOT-223 | TO-220 (Power Package) |

|---|---|---|

| Package Type | Surface Mount | Through-Hole |

| Typical Dimensions | 6.5mm x 3.5mm | 10mm x 15mm (Approx.) |

| Power Dissipation | Up to ~1.5W (with proper PCB heatsinking) | Up to 50W or more (with heatsink) |

| Thermal Resistance (Junction to Ambient) | ~70 degC/W | ~3-5 degC/W (with heatsink) |

| Package Material | Molded Plastic | Plastic body with metal tab |

| Lead Count | 3 Leads | 3 Leads + Metal Tab |

| Typical Applications | Low to moderate power ICs, regulators, small transistors | High power transistors, voltage regulators, power MOSFETs |

| Mounting | PCB Surface Mount | Through-Hole Mount with Heat Sink |

| Cost | Lower | Higher |

Introduction to SOT-223 and TO-220 Power Packages

SOT-223 and TO-220 are common power semiconductor packages designed for efficient heat dissipation and electrical performance. SOT-223 offers a compact, surface-mount solution ideal for moderate power applications, with a low thermal resistance and a large mounting pad for heat sinking. TO-220 features a larger, through-hole design with a metal tab for enhanced thermal conductivity and is preferred in high-power and high-current scenarios requiring robust mechanical stability.

Key Physical Differences: Size and Form Factor

The SOT-223 package is significantly smaller and more compact than the TO-220, measuring approximately 6.7 mm by 6.3 mm compared to the TO-220's larger size of about 10 mm by 15 mm, making it ideal for space-constrained applications. Your choice between these packages affects thermal performance and mounting options, as the TO-220 features a larger metal tab for improved heat dissipation and standard through-hole mounting, whereas the SOT-223 is surface-mount with a lower profile. These physical differences directly influence circuit design considerations, especially in power electronics where size and heat management are critical.

Thermal Performance Comparison

SOT-223 packages offer lower thermal resistance than TO-220 packages in compact applications, enabling efficient heat dissipation despite a smaller footprint. TO-220 packages typically provide superior thermal performance through larger metal tabs and the ability to attach external heatsinks, resulting in lower junction-to-ambient thermal resistance values. For high-power applications requiring effective thermal management, TO-220 is generally preferred, whereas SOT-223 suits moderately powered devices with space constraints.

Electrical Characteristics: Current and Voltage Handling

SOT-223 packages typically handle current up to 3A and voltage ratings around 30-60V, making them suitable for low to medium power applications, whereas TO-220 packages support higher current levels often exceeding 10A and voltage ratings that can surpass 250V, ideal for high-power dissipation circuits. Thermal resistance in TO-220 packages is generally lower, enhancing their capability to maintain electrical characteristics under elevated power loads. The choice between SOT-223 and TO-220 hinges on the specific current requirements and voltage tolerances of the application, with TO-220 preferred for demanding power handling.

Mounting Techniques: Surface-Mount vs. Through-Hole

SOT-223 packages utilize surface-mount technology (SMT), allowing direct placement and soldering onto PCB pads, which enhances automated assembly efficiency and reduces board space. TO-220 packages employ through-hole mounting, providing robust mechanical stability and superior heat dissipation via a metal tab connected to a heatsink, ideal for higher power applications. Understanding your circuit's thermal and assembly requirements will help determine whether the compact SMT of SOT-223 or the heat-resistant through-hole design of TO-220 best suits your power device integration.

Heat Dissipation Capabilities

SOT-223 and TO-220 power packages differ significantly in heat dissipation capabilities, with TO-220 offering superior thermal performance due to its larger metal tab and ability to attach an external heatsink. The TO-220 can typically dissipate several watts of power more efficiently, making it ideal for high-power applications requiring effective heat management. You should choose TO-220 when your design demands robust heat dissipation to prevent thermal stress and maintain device reliability.

Application Suitability and Use Cases

SOT-223 power packages are ideal for compact, low to medium power applications such as voltage regulators and small power transistors in consumer electronics due to their small footprint and efficient heat dissipation. TO-220 packages are preferred in high-power applications like power amplifiers, motor drivers, and voltage regulators requiring robust thermal management because of their larger size and ability to be mounted with heat sinks. Selecting between SOT-223 and TO-220 depends on power dissipation needs, circuit space constraints, and thermal performance requirements within the specific use case.

Cost Comparison and Availability

SOT-223 packages generally offer lower manufacturing costs due to their smaller size and suitability for automated surface-mount assembly, resulting in cost-effective solutions for medium-power applications. TO-220 packages, by contrast, tend to be more expensive because of their larger size, robust heat dissipation capabilities, and compatibility with through-hole mounting, which is preferred for high-power devices. Availability-wise, TO-220 components remain widely accessible across various power semiconductor categories, while SOT-223 devices are increasingly popular in compact, cost-sensitive designs but may have limited options for very high power ratings.

Reliability and Durability Considerations

The SOT-223 package offers better thermal performance with a smaller footprint, enhancing reliability in compact designs by efficiently dissipating heat and reducing stress on components. The TO-220 package is favored in high-power applications due to its robust construction and superior heat sinking capability, ensuring durability under heavy electrical loads and prolonged operation. Your choice should balance space constraints with thermal and mechanical stress requirements to maximize device lifespan and consistent performance.

Choosing the Right Power Package for Your Design

SOT-223 and TO-220 power packages offer distinct advantages depending on your design requirements, with SOT-223 providing a compact, low-profile option ideal for surface-mount applications and efficient heat dissipation in moderate power scenarios. TO-220 packages excel in handling higher power levels with superior thermal management through larger heatsinks and robust leads, suitable for applications demanding greater current capacity. Selecting the right power package impacts your device's reliability and thermal performance, ensuring your design meets space constraints and cooling needs effectively.

SOT-223 vs TO-220 (power package) Infographic

electrown.com

electrown.com