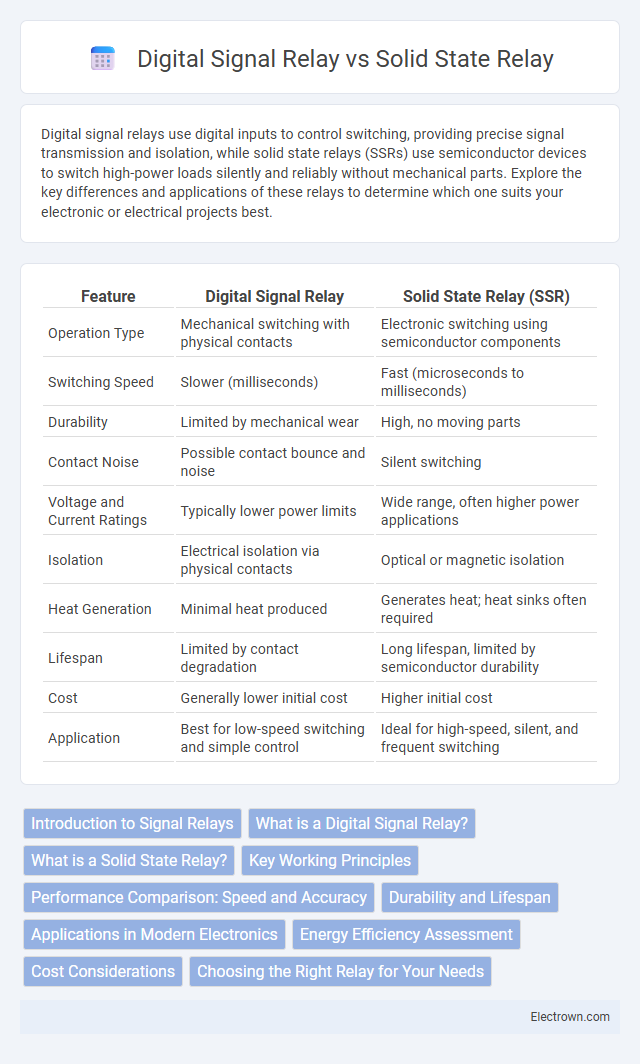

Digital signal relays use digital inputs to control switching, providing precise signal transmission and isolation, while solid state relays (SSRs) use semiconductor devices to switch high-power loads silently and reliably without mechanical parts. Explore the key differences and applications of these relays to determine which one suits your electronic or electrical projects best.

Table of Comparison

| Feature | Digital Signal Relay | Solid State Relay (SSR) |

|---|---|---|

| Operation Type | Mechanical switching with physical contacts | Electronic switching using semiconductor components |

| Switching Speed | Slower (milliseconds) | Fast (microseconds to milliseconds) |

| Durability | Limited by mechanical wear | High, no moving parts |

| Contact Noise | Possible contact bounce and noise | Silent switching |

| Voltage and Current Ratings | Typically lower power limits | Wide range, often higher power applications |

| Isolation | Electrical isolation via physical contacts | Optical or magnetic isolation |

| Heat Generation | Minimal heat produced | Generates heat; heat sinks often required |

| Lifespan | Limited by contact degradation | Long lifespan, limited by semiconductor durability |

| Cost | Generally lower initial cost | Higher initial cost |

| Application | Best for low-speed switching and simple control | Ideal for high-speed, silent, and frequent switching |

Introduction to Signal Relays

Signal relays, including digital signal relays and solid state relays, are crucial components in electronic systems that enable the control and switching of electrical signals. Digital signal relays utilize electromagnetic coils to physically open or close contacts, providing galvanic isolation and reliable switching for low-power signals. Solid state relays, on the other hand, use semiconductor devices like thyristors or transistors to perform switching without moving parts, resulting in faster response times, longer lifespan, and enhanced durability in high-frequency applications.

What is a Digital Signal Relay?

A Digital Signal Relay (DSR) is an electronic device used to transmit digital signals between circuits while providing isolation and amplification. It operates by converting digital input signals into corresponding output signals without mechanical movement, ensuring fast switching and reliable operation. Unlike Solid State Relays (SSRs), which switch electrical loads directly, DSRs focus on maintaining signal integrity in communication and control systems.

What is a Solid State Relay?

A Solid State Relay (SSR) is an electronic switching device that uses semiconductor components to switch electrical loads without moving parts, offering faster response times and increased reliability compared to mechanical relays. SSRs provide silent operation, resistance to vibration and shock, and longer lifespan due to the absence of physical contacts. If you need high-speed, durable, and maintenance-free switching for your digital signal control applications, a Solid State Relay is often the preferred choice.

Key Working Principles

Digital signal relays operate by using digital logic to control the electromagnetic coil, which mechanically opens or closes contacts to switch signals. Solid state relays rely on semiconductor components such as thyristors, triacs, or transistors to perform switching without moving parts, providing faster response times and increased durability. Your choice depends on the need for mechanical isolation and electrical noise tolerance, as solid state relays offer silent, vibration-resistant operation compared to digital signal relays.

Performance Comparison: Speed and Accuracy

Digital signal relays offer higher speed and precise signal control due to their ability to handle complex digital inputs with minimal delay, making them ideal for fast-switching applications. Solid state relays excel in accuracy by providing reliable, noise-free switching with no mechanical wear, ensuring consistent performance over long periods. In performance comparison, digital signal relays achieve superior speed, while solid state relays deliver enhanced accuracy and durability in signal switching tasks.

Durability and Lifespan

Digital signal relays typically feature mechanical components that may wear out over time, resulting in a limited lifespan ranging from hundreds of thousands to a few million operations. Solid state relays (SSRs), by contrast, have no moving parts, allowing for significantly higher durability and operational lifespans often exceeding 100 million cycles. SSRs also perform better in harsh environments due to their resistance to vibration and shock, enhancing their reliability and longevity in industrial applications.

Applications in Modern Electronics

Digital signal relays are essential in telecommunications, offering precise control for low-power signal switching in routers and modems. Solid state relays excel in industrial automation and HVAC systems, providing fast, reliable switching without mechanical wear. Both relays enhance modern electronics by improving efficiency, durability, and noise immunity in diverse applications.

Energy Efficiency Assessment

Digital signal relays typically consume less power during switching operations compared to solid state relays, resulting in higher energy efficiency for low-frequency applications. Solid state relays, while offering faster switching speeds and longer lifespan, can generate more heat due to continuous current leakage, impacting overall energy consumption. Evaluating your specific load and switching frequency is crucial to determine which relay type maximizes energy efficiency in your system.

Cost Considerations

Digital signal relays typically have lower initial costs compared to solid state relays due to simpler mechanical components. Solid state relays, while more expensive upfront, provide longer lifespan and reduced maintenance costs by eliminating moving parts. Total cost of ownership for solid state relays may be lower in high-reliability applications despite the higher purchase price.

Choosing the Right Relay for Your Needs

Choosing the right relay depends on your specific application requirements, such as switching speed, load type, and environmental conditions. Digital signal relays excel in precise, low-current signal switching with minimal electrical noise, making them ideal for sensitive instrumentation and communication systems. Solid state relays, featuring no moving parts, provide longer lifespan and fast switching for high voltage or current loads, ensuring reliability in industrial automation and power control applications.

Digital signal relay vs Solid state relay Infographic

electrown.com

electrown.com