Supercapacitors and ultracapacitors are often used interchangeably to describe energy storage devices that provide rapid charging and discharging capabilities with high power density and long cycle life. Explore the differences and applications to understand which technology best fits your energy storage needs in the detailed article.

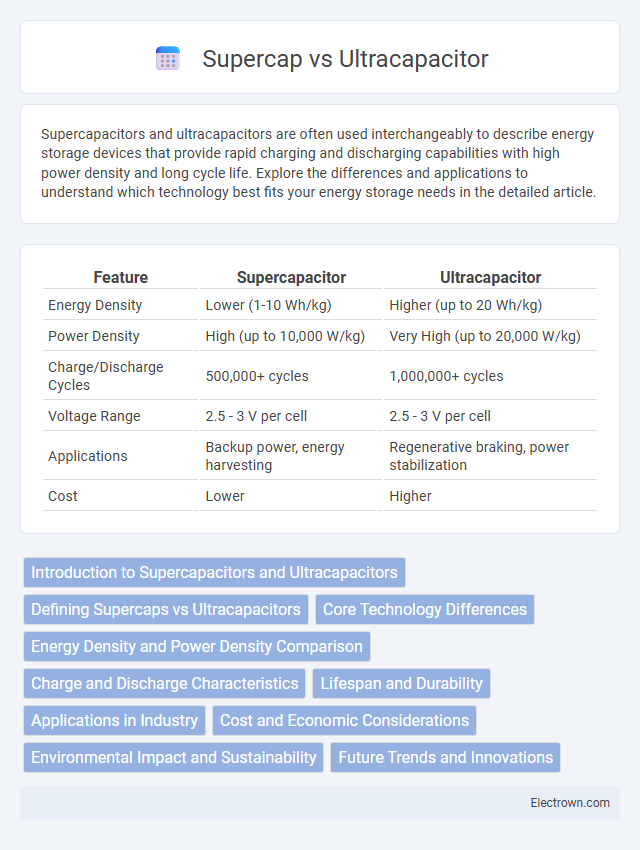

Table of Comparison

| Feature | Supercapacitor | Ultracapacitor |

|---|---|---|

| Energy Density | Lower (1-10 Wh/kg) | Higher (up to 20 Wh/kg) |

| Power Density | High (up to 10,000 W/kg) | Very High (up to 20,000 W/kg) |

| Charge/Discharge Cycles | 500,000+ cycles | 1,000,000+ cycles |

| Voltage Range | 2.5 - 3 V per cell | 2.5 - 3 V per cell |

| Applications | Backup power, energy harvesting | Regenerative braking, power stabilization |

| Cost | Lower | Higher |

Introduction to Supercapacitors and Ultracapacitors

Supercapacitors, also known as ultracapacitors, are advanced energy storage devices characterized by high power density and rapid charge-discharge cycles, bridging the gap between conventional capacitors and batteries. They utilize electrostatic double-layer capacitance and pseudocapacitance to achieve superior energy capacity and longer lifespan, making them ideal for applications requiring quick bursts of energy. Understanding the fundamentals of supercapacitors can help you optimize energy storage solutions in electronics, automotive, and renewable energy systems.

Defining Supercaps vs Ultracapacitors

Supercaps and ultracapacitors both refer to high-capacity electrochemical capacitors designed for rapid energy storage and release, often used interchangeably in the energy storage industry. Supercapacitors are characterized by their ability to deliver higher power density than batteries, with capacitance values typically ranging from a few farads up to several thousand farads. Ultracapacitors emphasize the advanced construction and materials, such as activated carbon electrodes and electrolytes, which enable higher energy density, longer cycle life, and faster charge/discharge rates compared to traditional capacitors.

Core Technology Differences

Supercapacitors and ultracapacitors primarily differ in their core technology, where supercapacitors use electrochemical double-layer capacitance for energy storage, enabling rapid charge and discharge cycles. Ultracapacitors combine electrochemical double-layer capacitance with pseudocapacitance from faradaic redox reactions, resulting in higher energy density and enhanced performance under demanding conditions. Your choice between the two hinges on the specific application requirements for energy storage efficiency and power delivery.

Energy Density and Power Density Comparison

Supercapacitors and ultracapacitors differ primarily in their energy density and power density, with ultracapacitors typically exhibiting higher energy density, often ranging from 5 to 10 Wh/kg, compared to standard supercapacitors that usually offer around 1 to 5 Wh/kg. Power density in both devices remains high, but supercapacitors can deliver up to 10,000 W/kg, outperforming many battery technologies, while ultracapacitors focus on balancing enhanced energy storage with substantial power output. The energy density advantage of ultracapacitors makes them suitable for applications requiring longer energy discharge, whereas supercapacitors excel in rapid charge-discharge cycles due to superior power density.

Charge and Discharge Characteristics

Supercaps and ultracapacitors both excel in rapid charge and discharge cycles, but ultracapacitors typically offer higher power density and faster response times due to advanced electrode materials and electrolyte formulations. Your choice between these energy storage devices depends on the application; ultracapacitors are preferred for short bursts of high power, while supercapacitors balance energy storage with quick charging ability. Understanding the specific charge and discharge characteristics helps optimize performance in applications like regenerative braking, power backup, or portable electronics.

Lifespan and Durability

Supercapacitors and ultracapacitors both offer exceptional lifespan and durability compared to traditional batteries, with rated cycle lives often exceeding 1 million charge-discharge cycles. Ultracapacitors typically maintain performance over a wider temperature range and resist degradation from deep discharges, enhancing long-term reliability in demanding applications. Your choice between these technologies should consider the specific endurance requirements and operational conditions to maximize system longevity.

Applications in Industry

Supercapacitors and ultracapacitors are critical components in industrial applications requiring rapid energy storage and delivery, such as renewable energy storage, electric vehicle power management, and backup power systems. Ultracapacitors, known for higher energy density, are increasingly used in heavy machinery for regenerative braking and grid stabilization, while supercapacitors excel in applications demanding high power output and long cycle life like industrial robotics and uninterruptible power supplies. Your choice between these technologies depends on specific industry needs around energy capacity, charge speed, and operational longevity.

Cost and Economic Considerations

Supercapacitors and ultracapacitors differ primarily in cost efficiency and economic viability, with ultracapacitors generally offering higher energy density but at a greater price per unit. Your choice depends on budget constraints and application demands, as supercapacitors tend to provide a more cost-effective solution for short-term energy storage and rapid charge/discharge cycles. Evaluating total lifecycle costs, including energy savings and maintenance, is crucial for optimizing investment in either technology.

Environmental Impact and Sustainability

Supercapacitors and ultracapacitors both offer environmentally friendly energy storage solutions with longer lifespans and higher cycle durability compared to traditional batteries, reducing waste generation. Ultracapacitors typically use carbon-based materials, which are more sustainable and easier to recycle, minimizing toxic chemical use and environmental pollution. The energy efficiency and rapid charge-discharge cycles of these technologies contribute to lower carbon footprints in applications such as renewable energy systems and electric vehicles.

Future Trends and Innovations

Supercap and ultracapacitor technologies are evolving with trends focusing on higher energy densities, faster charge-discharge cycles, and longer lifespans to meet expanding demands in electric vehicles and renewable energy storage. Innovations in electrode materials, such as graphene and carbon nanotubes, are driving significant improvements in capacitance and stability. Integration with smart energy management systems and hybrid storage solutions is shaping the future landscape of high-performance, sustainable energy storage devices.

Supercap vs Ultracapacitor Infographic

electrown.com

electrown.com