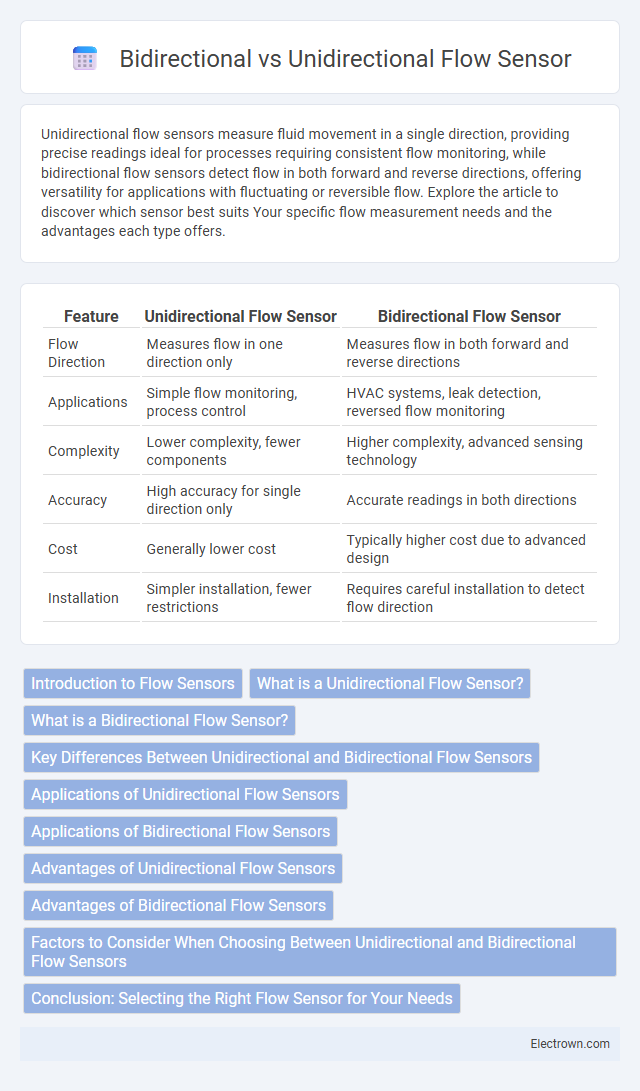

Unidirectional flow sensors measure fluid movement in a single direction, providing precise readings ideal for processes requiring consistent flow monitoring, while bidirectional flow sensors detect flow in both forward and reverse directions, offering versatility for applications with fluctuating or reversible flow. Explore the article to discover which sensor best suits Your specific flow measurement needs and the advantages each type offers.

Table of Comparison

| Feature | Unidirectional Flow Sensor | Bidirectional Flow Sensor |

|---|---|---|

| Flow Direction | Measures flow in one direction only | Measures flow in both forward and reverse directions |

| Applications | Simple flow monitoring, process control | HVAC systems, leak detection, reversed flow monitoring |

| Complexity | Lower complexity, fewer components | Higher complexity, advanced sensing technology |

| Accuracy | High accuracy for single direction only | Accurate readings in both directions |

| Cost | Generally lower cost | Typically higher cost due to advanced design |

| Installation | Simpler installation, fewer restrictions | Requires careful installation to detect flow direction |

Introduction to Flow Sensors

Flow sensors measure the rate and direction of fluid movement within pipes or systems, essential for accurate monitoring and control in industrial, automotive, and HVAC applications. Unidirectional flow sensors detect fluid flow in a single direction, providing precise measurements in systems where flow reversals are not expected. Bidirectional flow sensors monitor fluid movement both forward and backward, enabling comprehensive real-time data for processes requiring dynamic flow changes, ensuring your system operates efficiently and safely.

What is a Unidirectional Flow Sensor?

A unidirectional flow sensor measures fluid flow in a single, specified direction, ensuring accurate and consistent flow rate readings without interference from reverse flow. These sensors are commonly used in applications like water treatment and HVAC systems where flow direction is predetermined and stable. Choosing a unidirectional flow sensor helps maintain precise monitoring of your system's fluid dynamics, preventing errors caused by backflow.

What is a Bidirectional Flow Sensor?

A Bidirectional Flow Sensor measures fluid flow in both forward and reverse directions, providing accurate readings regardless of flow reversal. These sensors use advanced technologies such as ultrasonic or electromagnetic techniques to detect changes in flow velocity and direction. Incorporating a bidirectional flow sensor in your system ensures precise monitoring and control in applications where flow direction fluctuates.

Key Differences Between Unidirectional and Bidirectional Flow Sensors

Unidirectional flow sensors measure fluid movement in a single direction, providing accurate flow rate data ideal for applications where flow direction remains constant. Bidirectional flow sensors detect fluid flow in two directions, enabling monitoring and control in systems with reverse or variable flow, enhancing your process flexibility. Key differences include their directional sensitivity, installation requirements, and ability to measure flow reversal, which impact system design and performance optimization.

Applications of Unidirectional Flow Sensors

Unidirectional flow sensors are widely used in applications such as water treatment plants, HVAC systems, and fuel monitoring where fluid flow needs to be measured in a single predetermined direction. These sensors are ideal for ensuring accurate flow measurement in pipelines, preventing reverse flow errors, and maintaining system efficiency. Your industrial processes or equipment can benefit from their reliability in monitoring consistent, one-way fluid movement.

Applications of Bidirectional Flow Sensors

Bidirectional flow sensors are essential in applications requiring precise measurement of fluid flow in both directions, such as HVAC systems, water treatment plants, and medical devices like dialysis machines. These sensors enable accurate monitoring and control of reverse flow conditions in pipelines, ensuring system safety and efficiency. Their ability to detect flow direction changes makes them indispensable in automation and energy management sectors.

Advantages of Unidirectional Flow Sensors

Unidirectional flow sensors offer precise measurement by detecting fluid flow in a single direction, reducing complexity and minimizing the risk of inaccurate readings caused by reverse flow or turbulence. These sensors typically feature simpler designs, which enhance durability and lower maintenance costs compared to bidirectional counterparts. Their reliable performance in systems with consistent flow direction makes them ideal for applications such as water treatment, HVAC, and industrial process control.

Advantages of Bidirectional Flow Sensors

Bidirectional flow sensors provide precise measurement of fluid flow in both forward and reverse directions, enhancing system versatility and accuracy. They enable real-time monitoring of flow reversals, critical for applications like energy management and leak detection. Their ability to detect bidirectional flow reduces the need for multiple sensors, simplifying installation and lowering maintenance costs.

Factors to Consider When Choosing Between Unidirectional and Bidirectional Flow Sensors

Choosing between unidirectional and bidirectional flow sensors depends on factors such as the directionality of fluid flow, accuracy requirements, and application complexity. Unidirectional sensors are ideal for systems with a consistent flow direction, offering simpler installation and cost-effectiveness. Your selection should also consider the need for measuring flow reversals, where bidirectional sensors provide versatile data essential for processes like pump monitoring or leak detection.

Conclusion: Selecting the Right Flow Sensor for Your Needs

Choosing between unidirectional and bidirectional flow sensors depends on your specific application requirements, such as measurement accuracy, flow direction variability, and cost constraints. Unidirectional sensors provide precise readings for consistent flow direction, while bidirectional sensors offer flexibility for systems with reversible or fluctuating flow. Ensuring your selection aligns with your operational needs will optimize performance and reliability.

Unidirectional vs Bidirectional Flow Sensor Infographic

electrown.com

electrown.com