Dry heat sterilizers use high temperatures to destroy microorganisms by oxidation, making them ideal for materials that can withstand heat but might be damaged by moisture. Moist heat sterilizers employ steam under pressure to denature proteins and effectively eliminate microbes, offering faster sterilization suitable for heat-sensitive instruments. Discover which sterilization method best suits your needs by reading the rest of the article.

Table of Comparison

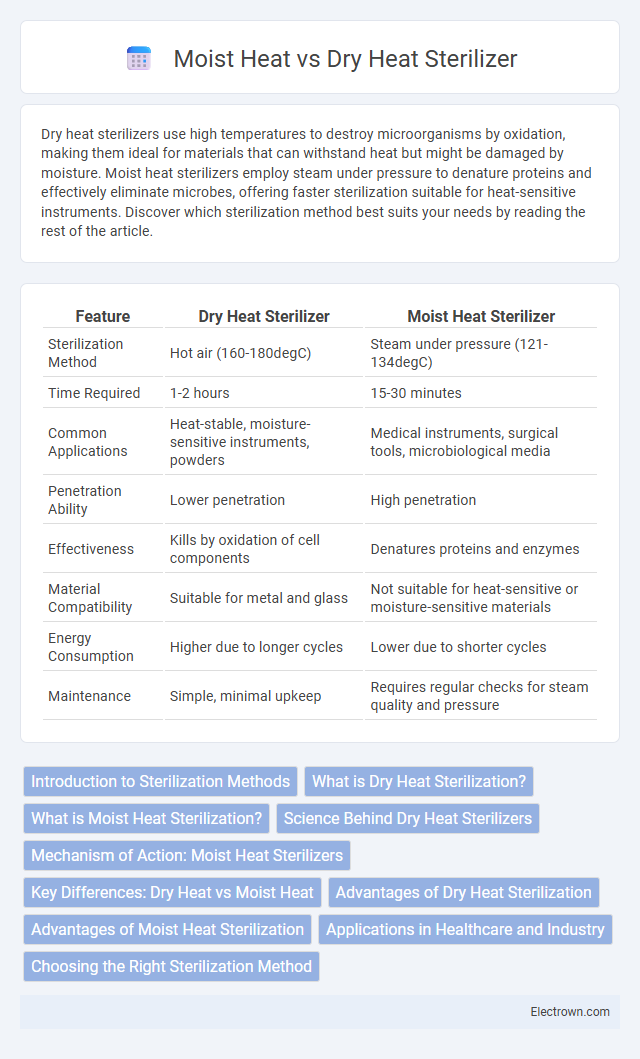

| Feature | Dry Heat Sterilizer | Moist Heat Sterilizer |

|---|---|---|

| Sterilization Method | Hot air (160-180degC) | Steam under pressure (121-134degC) |

| Time Required | 1-2 hours | 15-30 minutes |

| Common Applications | Heat-stable, moisture-sensitive instruments, powders | Medical instruments, surgical tools, microbiological media |

| Penetration Ability | Lower penetration | High penetration |

| Effectiveness | Kills by oxidation of cell components | Denatures proteins and enzymes |

| Material Compatibility | Suitable for metal and glass | Not suitable for heat-sensitive or moisture-sensitive materials |

| Energy Consumption | Higher due to longer cycles | Lower due to shorter cycles |

| Maintenance | Simple, minimal upkeep | Requires regular checks for steam quality and pressure |

Introduction to Sterilization Methods

Dry heat sterilizers use high temperatures to oxidize cell components and eliminate microorganisms without moisture, making them ideal for metal instruments and powders. Moist heat sterilization employs steam under pressure to denature proteins and destroy bacteria, viruses, and spores effectively, commonly used for surgical tools and laboratory equipment. Understanding your sterilization needs helps select the appropriate method to ensure safety and maintain the integrity of your materials.

What is Dry Heat Sterilization?

Dry heat sterilization uses hot air with temperatures typically between 160degC and 180degC to eliminate microorganisms by oxidation, ideal for materials that can withstand high temperatures without moisture damage such as powders, oils, and metal instruments. This method requires longer exposure times compared to moist heat sterilization, often ranging from 1 to 2 hours depending on the temperature. Dry heat sterilizers operate without steam, making them suitable for heat-stable, moisture-sensitive items where moisture could compromise the sterilization process or product integrity.

What is Moist Heat Sterilization?

Moist heat sterilization uses saturated steam under pressure to efficiently eliminate microorganisms, including spores, from medical instruments and laboratory equipment. This method operates at temperatures between 121degC and 134degC, typically within an autoclave, ensuring rapid penetration and destruction of pathogens. Moist heat is preferred for its effectiveness in sterilizing heat- and moisture-resistant items without causing damage.

Science Behind Dry Heat Sterilizers

Dry heat sterilizers use high temperatures, typically ranging from 160degC to 180degC, to oxidize cell components and denature proteins, effectively killing microorganisms through a process called thermal destruction. Unlike moist heat sterilizers, which rely on steam and moisture to penetrate and coagulate microbial proteins, dry heat sterilization requires longer exposure times due to its mechanism involving heat conduction and oxidation. This method is ideal for sterilizing materials that can withstand high temperatures without moisture damage, such as powders, oils, and metal instruments.

Mechanism of Action: Moist Heat Sterilizers

Moist heat sterilizers use saturated steam under pressure to coagulate proteins, effectively killing microorganisms, including spores. This method penetrates materials quickly and evenly, ensuring thorough sterilization at lower temperatures compared to dry heat. You can rely on moist heat sterilizers for efficient and rapid sterilization in medical, laboratory, and industrial settings.

Key Differences: Dry Heat vs Moist Heat

Dry heat sterilizers use high temperatures ranging from 160degC to 180degC for 1 to 2 hours without moisture, effectively killing microorganisms by protein oxidation, ideal for materials sensitive to moisture like powders and oils. Moist heat sterilizers, such as autoclaves, utilize pressurized steam at temperatures of 121degC to 134degC for 15 to 30 minutes, achieving rapid and effective sterilization through protein denaturation, suitable for surgical instruments and media. Key differences include dry heat's longer exposure time and absence of moisture versus moist heat's faster action and reliance on steam, impacting the choice based on material compatibility and sterilization efficiency.

Advantages of Dry Heat Sterilization

Dry heat sterilization offers several advantages, including the ability to sterilize materials that can be damaged by moisture, such as powders, oils, and metal instruments. It also provides better penetration for certain materials and avoids corrosion and rusting, which often occur with moist heat methods. Your instruments remain dry and ready for immediate use, making dry heat sterilizers ideal for heat-resistant, moisture-sensitive items.

Advantages of Moist Heat Sterilization

Moist heat sterilization offers superior penetration and faster processing times compared to dry heat methods, effectively destroying a wide range of microorganisms, including spores. It operates at lower temperatures, which helps preserve the integrity of heat-sensitive instruments and reduces energy consumption. Your sterilization process benefits from reliable microbial kill rates and cost efficiency when using moist heat sterilizers, such as autoclaves.

Applications in Healthcare and Industry

Dry heat sterilizers effectively eliminate microorganisms on metal instruments, glassware, and powders in healthcare and industrial laboratories by using high temperatures for extended periods, ideal for materials sensitive to moisture. Moist heat sterilizers, such as autoclaves, utilize steam under pressure to rapidly sterilize surgical tools, media, and biohazard waste, making them essential in hospitals and pharmaceutical manufacturing for ensuring sterility without damaging heat-sensitive items. Your choice between dry heat and moist heat sterilization depends on the type of materials, desired cycle time, and specific contamination challenges in healthcare and industrial settings.

Choosing the Right Sterilization Method

Choosing the right sterilization method depends on the type of instruments and materials you're processing. Dry heat sterilizers are ideal for metal instruments and powders that may be damaged by moisture, while moist heat sterilizers, such as autoclaves, effectively eliminate microorganisms on surgical tools and linens through steam under pressure. Understanding your equipment's material compatibility and sterilization goals ensures optimal microbial control and instrument longevity.

Dry Heat vs Moist Heat Sterilizer Infographic

electrown.com

electrown.com