Piezoresistive pressure sensors detect pressure changes by measuring variations in electrical resistance caused by mechanical strain, offering fast response times and high sensitivity for precise applications. Understanding how capacitive sensors use changes in capacitance to measure pressure can help you choose the best technology for your needs--explore the rest of the article to learn more.

Table of Comparison

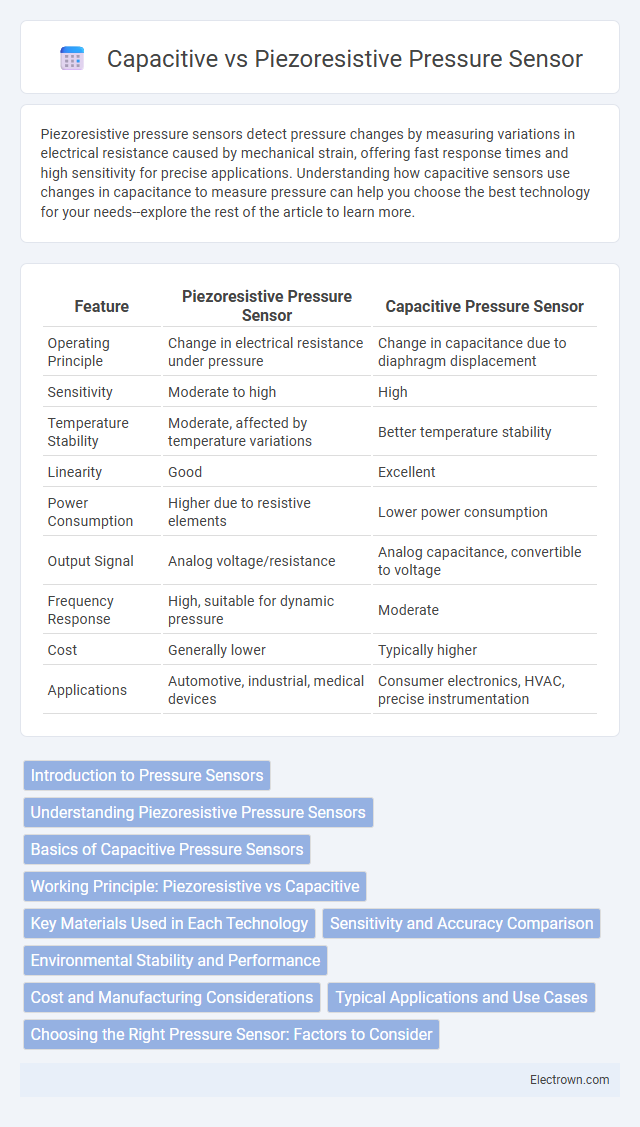

| Feature | Piezoresistive Pressure Sensor | Capacitive Pressure Sensor |

|---|---|---|

| Operating Principle | Change in electrical resistance under pressure | Change in capacitance due to diaphragm displacement |

| Sensitivity | Moderate to high | High |

| Temperature Stability | Moderate, affected by temperature variations | Better temperature stability |

| Linearity | Good | Excellent |

| Power Consumption | Higher due to resistive elements | Lower power consumption |

| Output Signal | Analog voltage/resistance | Analog capacitance, convertible to voltage |

| Frequency Response | High, suitable for dynamic pressure | Moderate |

| Cost | Generally lower | Typically higher |

| Applications | Automotive, industrial, medical devices | Consumer electronics, HVAC, precise instrumentation |

Introduction to Pressure Sensors

Pressure sensors measure force exerted by liquids or gases by converting physical pressure into an electrical signal. Piezoresistive sensors detect pressure through changes in electrical resistance caused by mechanical stress, offering high sensitivity and accuracy for dynamic applications. Capacitive sensors measure pressure by detecting variations in capacitance between two plates, providing excellent stability and low power consumption ideal for precise, low-frequency monitoring.

Understanding Piezoresistive Pressure Sensors

Piezoresistive pressure sensors convert mechanical pressure into an electrical resistance change, offering high sensitivity and fast response times ideal for detecting dynamic pressure variations. These sensors use semiconductor materials whose resistivity alters under mechanical stress, enabling precise measurement of pressure fluctuations in various applications like automotive, medical, and industrial systems. Understanding the working principle of piezoresistive sensors helps you select the right sensor for tasks requiring accurate, reliable pressure monitoring.

Basics of Capacitive Pressure Sensors

Capacitive pressure sensors measure pressure by detecting changes in capacitance caused by the deformation of a diaphragm under applied pressure, which alters the distance between conductive plates. These sensors offer high sensitivity, low power consumption, and excellent stability over a wide temperature range. Your choice of capacitive pressure sensors ensures accurate pressure measurements in applications demanding precise and reliable data.

Working Principle: Piezoresistive vs Capacitive

Piezoresistive pressure sensors operate by detecting changes in electrical resistance caused by mechanical strain on a semiconductor material when pressure is applied. Capacitive pressure sensors measure pressure by monitoring changes in capacitance between two conductive plates separated by a dielectric material, which varies as pressure alters the distance between the plates. The piezoresistive sensor translates mechanical deformation directly into a resistance change, while the capacitive sensor converts physical displacement into a capacitance change, enabling precise pressure measurement through different physical mechanisms.

Key Materials Used in Each Technology

Piezoresistive pressure sensors primarily utilize silicon-based materials, such as doped silicon or polysilicon, for their sensitive elements due to their excellent piezoresistive properties and linear response to pressure changes. Capacitive pressure sensors commonly employ materials like silicon, glass, and metal electrodes separated by a dielectric layer, often silicon dioxide or air gaps, to measure pressure through changes in capacitance caused by diaphragm deformation. The choice of materials directly impacts sensitivity, temperature stability, and fabrication complexity in both sensor types.

Sensitivity and Accuracy Comparison

Piezoresistive pressure sensors exhibit high sensitivity due to their ability to convert mechanical stress into a measurable change in electrical resistance, making them ideal for detecting small pressure variations with rapid response times. Capacitive pressure sensors offer superior accuracy and stability by measuring changes in capacitance caused by diaphragm displacement, which reduces temperature drift and noise interference. While piezoresistive sensors excel in sensitivity and speed, capacitive sensors provide enhanced precision and long-term reliability in pressure measurement applications.

Environmental Stability and Performance

Piezoresistive pressure sensors exhibit high sensitivity but can suffer from drift and reduced accuracy under extreme temperature or humidity conditions, impacting environmental stability. Capacitive pressure sensors maintain consistent performance and stability across a wider range of temperatures and environmental variations due to their low power consumption and minimal signal drift. Your choice depends on the need for stable, long-term measurements in harsh environments versus higher sensitivity in controlled conditions.

Cost and Manufacturing Considerations

Piezoresistive pressure sensors generally offer lower production costs due to simpler manufacturing processes and the use of standard semiconductor materials, making them ideal for high-volume, budget-sensitive applications. Capacitive pressure sensors require more complex fabrication techniques, including precise micromachining and dielectric layer deposition, which increases manufacturing expenses. Your choice between these sensors should factor in budget constraints and the scale of production to optimize cost-efficiency.

Typical Applications and Use Cases

Piezoresistive pressure sensors are widely used in automotive systems for monitoring oil and fuel pressure, industrial equipment for detecting fluid levels, and medical devices such as blood pressure monitors due to their high accuracy and sensitivity. Capacitive pressure sensors excel in HVAC systems, touchscreens, and altimeters where stability, low power consumption, and resistance to environmental interference are critical. Both sensor types find applications in aerospace for altitude measurement and robotics for tactile sensing, tailored to specific performance requirements like response time and environmental robustness.

Choosing the Right Pressure Sensor: Factors to Consider

When choosing the right pressure sensor, consider sensitivity, measurement range, and environmental conditions, as piezoresistive sensors excel in high-sensitivity applications with dynamic pressure changes, while capacitive sensors offer better stability and accuracy in low-pressure or static environments. Your application's temperature tolerance, signal processing requirements, and cost constraints also play critical roles in determining whether a piezoresistive or capacitive sensor fits best. Evaluating response time and long-term reliability ensures optimal sensor performance tailored to your specific industrial or medical use case.

Piezoresistive vs Capacitive Pressure Sensor Infographic

electrown.com

electrown.com