Galvanic dissolved oxygen sensors generate a current through a chemical reaction to measure oxygen levels, while optical sensors use luminescence quenching for more precise and low-maintenance readings. Explore the key differences and determine which sensor best suits your application by reading the full article.

Table of Comparison

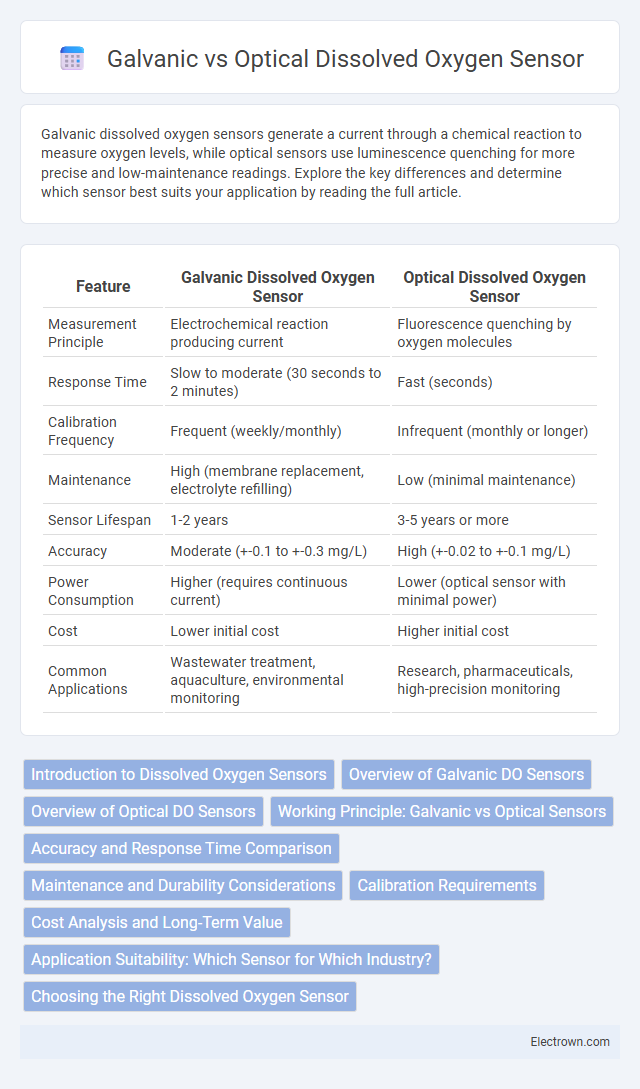

| Feature | Galvanic Dissolved Oxygen Sensor | Optical Dissolved Oxygen Sensor |

|---|---|---|

| Measurement Principle | Electrochemical reaction producing current | Fluorescence quenching by oxygen molecules |

| Response Time | Slow to moderate (30 seconds to 2 minutes) | Fast (seconds) |

| Calibration Frequency | Frequent (weekly/monthly) | Infrequent (monthly or longer) |

| Maintenance | High (membrane replacement, electrolyte refilling) | Low (minimal maintenance) |

| Sensor Lifespan | 1-2 years | 3-5 years or more |

| Accuracy | Moderate (+-0.1 to +-0.3 mg/L) | High (+-0.02 to +-0.1 mg/L) |

| Power Consumption | Higher (requires continuous current) | Lower (optical sensor with minimal power) |

| Cost | Lower initial cost | Higher initial cost |

| Common Applications | Wastewater treatment, aquaculture, environmental monitoring | Research, pharmaceuticals, high-precision monitoring |

Introduction to Dissolved Oxygen Sensors

Dissolved oxygen sensors measure oxygen concentration in water, crucial for environmental monitoring and industrial processes. Galvanic sensors generate a current proportional to oxygen levels through a chemical reaction, offering fast response and low maintenance. Optical sensors use luminescent technology for precise, long-term stability and minimal calibration, making them ideal for diverse aquatic applications.

Overview of Galvanic DO Sensors

Galvanic dissolved oxygen sensors operate using an electrochemical reaction between oxygen and electrodes immersed in an electrolyte, producing a current proportional to the oxygen concentration. These sensors offer rapid response times and low power consumption, making them ideal for continuous monitoring in water treatment and aquaculture applications. Your choice of a Galvanic DO sensor ensures reliable oxygen measurement with minimal maintenance due to its self-polarizing design and simple construction.

Overview of Optical DO Sensors

Optical dissolved oxygen sensors measure oxygen concentration using luminescent technology, offering high accuracy and low maintenance compared to galvanic sensors. These sensors utilize a fluorescent dye whose light emission changes based on oxygen levels, providing rapid response times and resistance to fouling. Optical DO sensors are ideal for long-term monitoring in environmental and industrial applications requiring precise oxygen measurements.

Working Principle: Galvanic vs Optical Sensors

Galvanic dissolved oxygen sensors operate based on an electrochemical reaction where oxygen diffuses through a membrane and reacts at the cathode, generating a current proportional to the oxygen concentration. Optical dissolved oxygen sensors utilize luminescence quenching, where oxygen molecules quench the luminescent dye's emission, and the sensor measures the change in fluorescence lifetime or intensity to determine oxygen levels. Both principles offer distinct advantages: galvanic sensors provide rapid response with steady-state current output, while optical sensors offer high sensitivity, low maintenance, and immunity to electrical noise.

Accuracy and Response Time Comparison

Galvanic dissolved oxygen sensors offer stable accuracy with moderate response times, typically around 10 to 30 seconds, making them reliable for general water quality monitoring. Optical dissolved oxygen sensors provide superior accuracy with precision often reaching +-0.1 mg/L and significantly faster response times, generally under 20 seconds, due to luminescence quenching technology. The advanced sensing mechanism in optical sensors reduces calibration frequency and enhances measurement stability across varying environmental conditions.

Maintenance and Durability Considerations

Galvanic dissolved oxygen sensors require regular electrolyte replacement and membrane changes to maintain accuracy, making their upkeep more hands-on compared to optical sensors. Optical dissolved oxygen sensors feature solid-state components and no membranes, resulting in lower maintenance needs and longer durability in harsh environments. Choosing your sensor depends on balancing the simplicity of maintenance with the expected longevity and environmental conditions of your application.

Calibration Requirements

Galvanic dissolved oxygen sensors require regular calibration due to their consumption of oxygen during measurement, which can lead to signal drift over time. Optical dissolved oxygen sensors offer longer calibration intervals because they use luminescence quenching technology, providing stable and more consistent readings without oxygen depletion. Optical sensors typically need calibration only once per year, whereas galvanic sensors often require monthly or biweekly calibrations to maintain accuracy.

Cost Analysis and Long-Term Value

Galvanic dissolved oxygen sensors generally offer lower upfront costs, making them attractive for budget-conscious applications, while optical sensors come with higher initial investment due to advanced technology. However, optical sensors provide longer lifespans, reduced maintenance requirements, and higher accuracy, leading to greater long-term value and lower total cost of ownership. Your choice should weigh initial expenditure against operational efficiency and longevity for optimal cost-benefit balance.

Application Suitability: Which Sensor for Which Industry?

Galvanic dissolved oxygen sensors are ideal for wastewater treatment and aquaculture due to their low maintenance and robust performance in harsh environments, providing reliable measurements in biological processes. Optical dissolved oxygen sensors are preferred in pharmaceutical and food and beverage industries for their high accuracy, fast response time, and minimal drift, ensuring precise monitoring in sterile and controlled conditions. You should select a galvanic sensor for cost-effective, rugged applications and an optical sensor when precision and longevity are critical for your industry.

Choosing the Right Dissolved Oxygen Sensor

Selecting the right dissolved oxygen sensor depends on your application requirements, maintenance preferences, and response time needs. Galvanic sensors offer quick startup and lower maintenance, ideal for continuous monitoring in harsh environments, while optical sensors provide higher accuracy, longer lifespan, and reduced calibration frequency, making them suitable for precise laboratory measurements or long-term deployment. Your choice should balance cost, sensitivity, and operational conditions to ensure reliable dissolved oxygen measurements.

Galvanic vs Optical Dissolved Oxygen Sensor Infographic

electrown.com

electrown.com