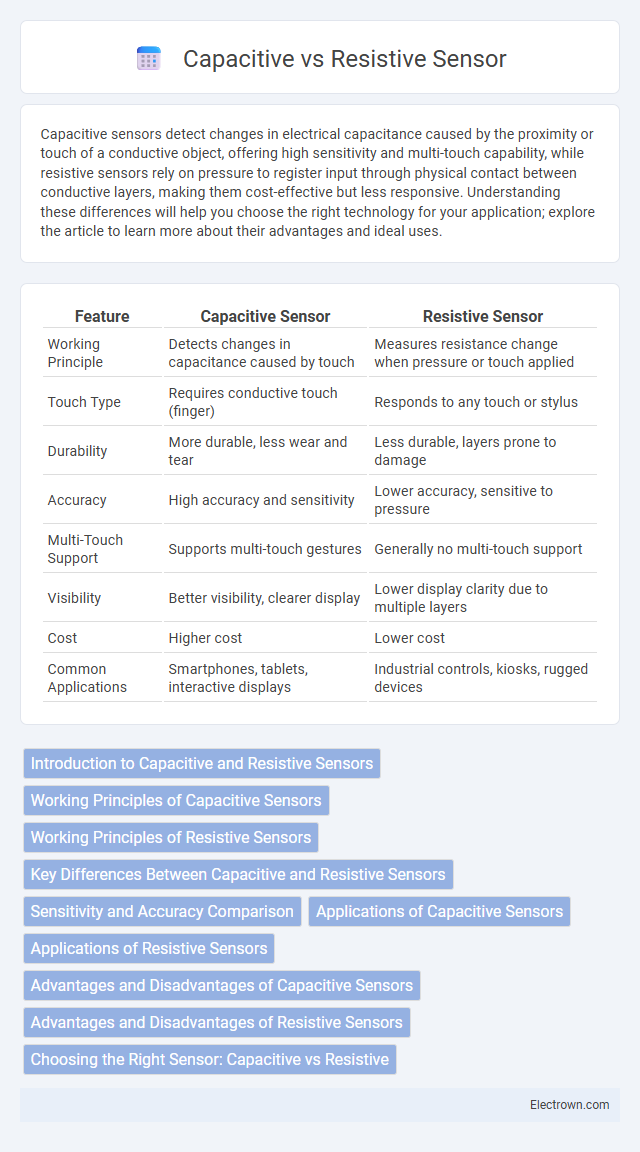

Capacitive sensors detect changes in electrical capacitance caused by the proximity or touch of a conductive object, offering high sensitivity and multi-touch capability, while resistive sensors rely on pressure to register input through physical contact between conductive layers, making them cost-effective but less responsive. Understanding these differences will help you choose the right technology for your application; explore the article to learn more about their advantages and ideal uses.

Table of Comparison

| Feature | Capacitive Sensor | Resistive Sensor |

|---|---|---|

| Working Principle | Detects changes in capacitance caused by touch | Measures resistance change when pressure or touch applied |

| Touch Type | Requires conductive touch (finger) | Responds to any touch or stylus |

| Durability | More durable, less wear and tear | Less durable, layers prone to damage |

| Accuracy | High accuracy and sensitivity | Lower accuracy, sensitive to pressure |

| Multi-Touch Support | Supports multi-touch gestures | Generally no multi-touch support |

| Visibility | Better visibility, clearer display | Lower display clarity due to multiple layers |

| Cost | Higher cost | Lower cost |

| Common Applications | Smartphones, tablets, interactive displays | Industrial controls, kiosks, rugged devices |

Introduction to Capacitive and Resistive Sensors

Capacitive sensors detect changes in capacitance caused by the proximity or touch of a conductive object, making them highly responsive to human touch and suitable for sleek, modern touchscreen devices. Resistive sensors operate based on pressure applied to layered flexible materials, causing electrical contact between conductive layers and registering the touch position, ideal for environments requiring durability and stylus input. The fundamental difference lies in capacitive sensors relying on electrical properties while resistive sensors depend on mechanical pressure to function effectively.

Working Principles of Capacitive Sensors

Capacitive sensors detect changes in capacitance caused by the presence or proximity of an object, relying on the variation in an electric field between two conductive plates. These sensors measure changes in the dielectric constant when your finger or a conductive material approaches the sensor surface, altering the capacitance value. The working principle enables high sensitivity and accuracy for touch detection in various applications, including smartphones and industrial controls.

Working Principles of Resistive Sensors

Resistive sensors operate by detecting changes in electrical resistance when pressure or force is applied to a conductive material. The sensor consists of multiple layers, including resistive and conductive components, that alter resistance values proportional to the applied mechanical stress. This variation in resistance is measured and converted into an electrical signal, enabling precise detection of touch or pressure.

Key Differences Between Capacitive and Resistive Sensors

Capacitive sensors detect changes in electrical capacitance caused by the proximity or touch of a conductive object, making them highly sensitive and capable of multi-touch input, whereas resistive sensors operate based on pressure applied to layers that complete an electrical circuit. Capacitive sensors offer better durability and clarity under most conditions but are less effective with gloves or non-conductive materials, while resistive sensors work with any object pressing down and are often more cost-effective. Your choice depends on the required sensitivity, environmental conditions, and interaction type for optimal sensor performance.

Sensitivity and Accuracy Comparison

Capacitive sensors offer higher sensitivity due to their ability to detect minute changes in capacitance when in contact with conductive materials like human skin, making them ideal for precise touch applications. Resistive sensors rely on pressure causing two layers to touch, providing lower sensitivity and accuracy, particularly under light touches or varying environmental conditions. Your choice should consider that capacitive sensors excel in accuracy and responsiveness, enhancing user interaction accuracy.

Applications of Capacitive Sensors

Capacitive sensors are widely used in touchscreen devices, proximity sensing, and liquid level detection due to their high sensitivity and durability. These sensors excel in applications requiring non-contact detection, such as gesture recognition and automotive parking assistance. Your electronic projects can benefit from capacitive sensors for precise measurement and enhanced user interaction capabilities.

Applications of Resistive Sensors

Resistive sensors are widely used in applications such as touchscreens for industrial equipment, where durability and cost-effectiveness are critical. They are ideal for environments requiring operation with gloves or styluses, making them suitable for medical devices and automotive controls. Your choice of resistive sensors ensures reliable performance in harsh conditions with precise pressure detection.

Advantages and Disadvantages of Capacitive Sensors

Capacitive sensors offer high sensitivity and fast response times, making them ideal for detecting materials without direct contact and enabling multi-touch capabilities in devices like smartphones. They exhibit excellent durability and resistance to contaminants such as dust and moisture, which enhances their reliability in various environments. However, capacitive sensors can be less effective with conductive liquids and may require complex calibration to minimize false triggers caused by environmental factors.

Advantages and Disadvantages of Resistive Sensors

Resistive sensors offer the advantage of detecting input from any object, including gloved fingers or a stylus, making them versatile for diverse environments. They are generally cost-effective and resistant to electrical noise, but their surface is more prone to wear and damage, reducing durability over time. Your choice may depend on the need for reliability in harsh conditions versus the potential for less sensitivity compared to capacitive alternatives.

Choosing the Right Sensor: Capacitive vs Resistive

Choosing the right sensor between capacitive and resistive types depends on the application's environmental conditions and required sensitivity. Capacitive sensors excel in multi-touch support and durability in clean, dry environments, offering high accuracy and faster response times. Resistive sensors perform better in harsh or wet conditions, as they detect pressure through physical contact, making them ideal for gloves or stylus use despite lower image clarity and touchscreen sensitivity.

Capacitive vs Resistive Sensor Infographic

electrown.com

electrown.com