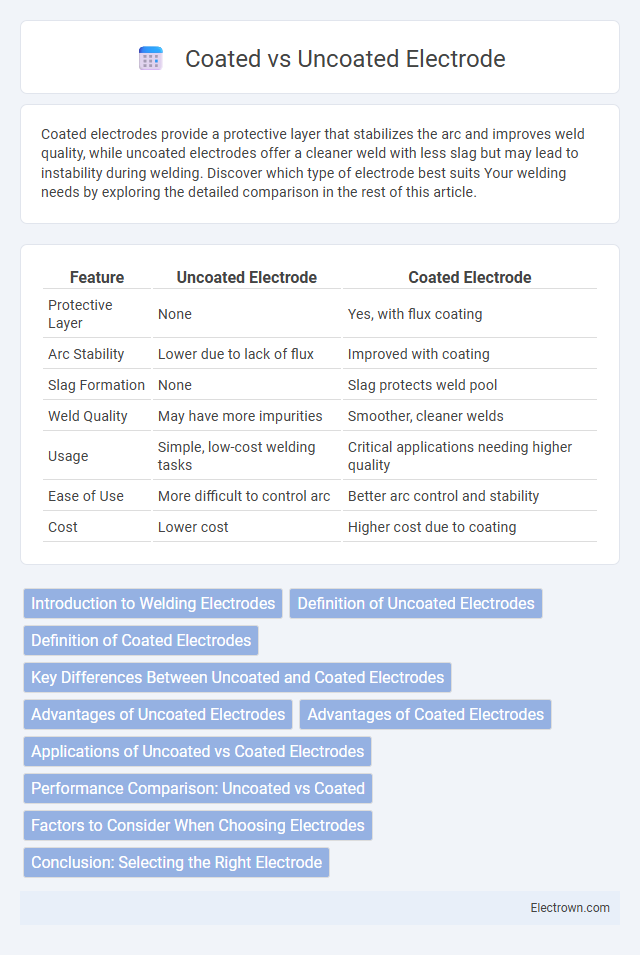

Coated electrodes provide a protective layer that stabilizes the arc and improves weld quality, while uncoated electrodes offer a cleaner weld with less slag but may lead to instability during welding. Discover which type of electrode best suits Your welding needs by exploring the detailed comparison in the rest of this article.

Table of Comparison

| Feature | Uncoated Electrode | Coated Electrode |

|---|---|---|

| Protective Layer | None | Yes, with flux coating |

| Arc Stability | Lower due to lack of flux | Improved with coating |

| Slag Formation | None | Slag protects weld pool |

| Weld Quality | May have more impurities | Smoother, cleaner welds |

| Usage | Simple, low-cost welding tasks | Critical applications needing higher quality |

| Ease of Use | More difficult to control arc | Better arc control and stability |

| Cost | Lower cost | Higher cost due to coating |

Introduction to Welding Electrodes

Welding electrodes are essential components in the welding process, serving as the medium to conduct current and create the weld. Uncoated electrodes, typically consisting of a bare metal core, offer good electrical conductivity and are commonly used for welding low-carbon steels. Coated electrodes feature a flux coating that stabilizes the arc, protects the weld pool from contamination, and can improve mechanical properties, making them suitable for various metals and welding conditions.

Definition of Uncoated Electrodes

Uncoated electrodes, also known as bare or bare-metal electrodes, consist solely of the metal core without any flux or coating applied to their surface. These electrodes rely on the intrinsic properties of the metal to conduct electricity and create the weld, typically requiring an external shielding gas to protect the molten weld pool from atmospheric contamination. Commonly used in applications demanding simplicity and lower cost, uncoated electrodes offer less slag formation and are favored for clean environments.

Definition of Coated Electrodes

Coated electrodes are welding rods covered with a layer of flux material that stabilizes the arc and protects the weld pool from atmospheric contamination. This flux coating enhances slag formation, improves weld quality, and controls the bead shape and penetration. Unlike uncoated electrodes, coated electrodes ensure better mechanical properties and reduce spatter during welding processes.

Key Differences Between Uncoated and Coated Electrodes

Uncoated electrodes lack a protective flux coating, leading to limited arc stability and higher susceptibility to contamination during welding, whereas coated electrodes feature flux coatings that enhance arc stability, improve weld quality, and provide slag protection. The coating type on electrodes influences spatter levels, penetration depth, and ease of weld control, making coated electrodes preferable for precise and clean weld joints. Your choice between uncoated and coated electrodes affects welding performance, maintenance, and final weld integrity, depending on the specific application requirements.

Advantages of Uncoated Electrodes

Uncoated electrodes offer superior arc stability and self-shielding properties, reducing the need for external shielding gas and simplifying welding setups. Their slag formation is easily removable, improving weld quality and minimizing post-weld cleanup time. Choosing uncoated electrodes can enhance productivity and reduce costs in welding applications requiring strong, consistent penetration.

Advantages of Coated Electrodes

Coated electrodes provide superior arc stability and reduce spatter, resulting in cleaner welds with minimal post-weld cleanup. They offer enhanced protection against atmospheric contamination, improving weld quality and mechanical properties. Your welding process benefits from easier handling and better control due to the flux coating that stabilizes the arc and produces slag shielding.

Applications of Uncoated vs Coated Electrodes

Uncoated electrodes are primarily used in applications requiring high chemical stability and resistance to contamination, such as in electrochemical sensors and corrosion studies. Coated electrodes, with their enhanced surface properties, find widespread use in welding processes and electroplating, where improved conductivity and durability are essential. Understanding your specific application needs helps determine the optimal choice between uncoated and coated electrodes for performance and longevity.

Performance Comparison: Uncoated vs Coated

Uncoated electrodes offer consistent arc stability and are ideal for applications requiring easy slag removal and welding on rusty or dirty metals, but they generally produce lower deposition rates and less smooth finishes compared to coated electrodes. Coated electrodes enhance arc control, improve weld bead quality, and provide better protection against oxidation and contamination due to their flux coating, resulting in superior mechanical properties and reduced spatter. The performance difference is especially significant in applications demanding higher strength and precision, where coated electrodes deliver more reliable and durable welds.

Factors to Consider When Choosing Electrodes

Selecting between uncoated and coated electrodes depends on factors such as the welding application, material compatibility, and desired weld quality. Uncoated electrodes are typically preferred for general-purpose welding due to their ease of use and lower cost, while coated electrodes offer enhanced arc stability, slag protection, and mechanical properties essential for critical or specialized projects. Consider the welding environment, current type, and positional requirements to optimize electrode performance and ensure structural integrity.

Conclusion: Selecting the Right Electrode

Selecting the right electrode depends on the specific welding application, material type, and desired weld quality. Uncoated electrodes provide deep penetration and are suitable for outdoor or heavy-duty environments, while coated electrodes offer better arc stability, slag control, and cleaner welds ideal for precision work. Evaluating factors like mechanical properties, environmental conditions, and post-weld requirements ensures optimal electrode choice for performance and durability.

Uncoated vs Coated Electrode Infographic

electrown.com

electrown.com