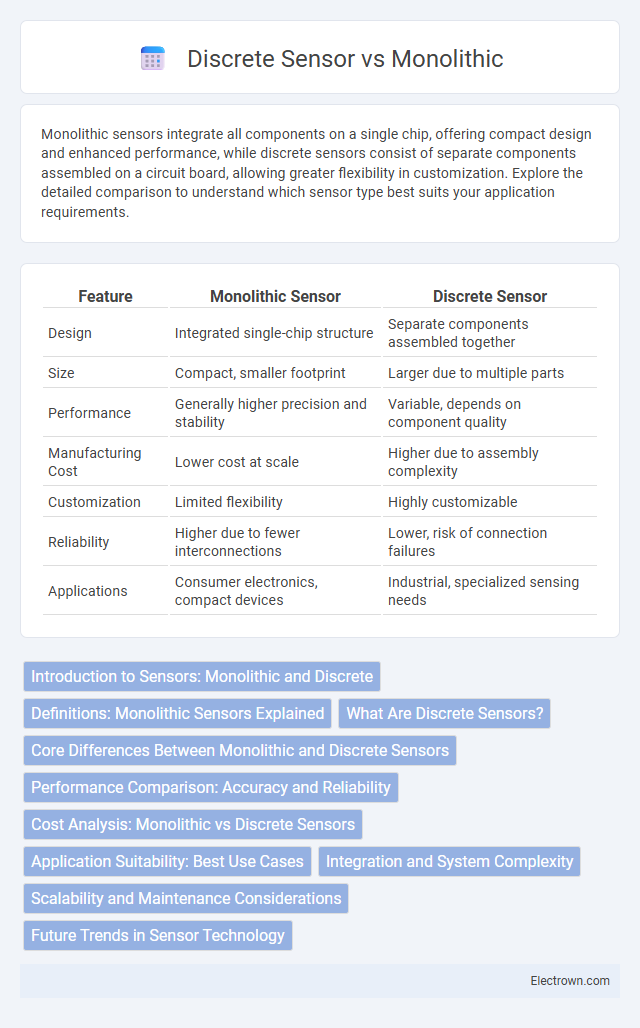

Monolithic sensors integrate all components on a single chip, offering compact design and enhanced performance, while discrete sensors consist of separate components assembled on a circuit board, allowing greater flexibility in customization. Explore the detailed comparison to understand which sensor type best suits your application requirements.

Table of Comparison

| Feature | Monolithic Sensor | Discrete Sensor |

|---|---|---|

| Design | Integrated single-chip structure | Separate components assembled together |

| Size | Compact, smaller footprint | Larger due to multiple parts |

| Performance | Generally higher precision and stability | Variable, depends on component quality |

| Manufacturing Cost | Lower cost at scale | Higher due to assembly complexity |

| Customization | Limited flexibility | Highly customizable |

| Reliability | Higher due to fewer interconnections | Lower, risk of connection failures |

| Applications | Consumer electronics, compact devices | Industrial, specialized sensing needs |

Introduction to Sensors: Monolithic and Discrete

Monolithic sensors integrate all sensing elements and electronics onto a single chip, offering compact design and enhanced signal processing capabilities. Discrete sensors consist of separate components for sensing and signal conditioning, allowing flexible customization and easier maintenance. Choosing between monolithic and discrete sensors depends on application requirements such as size constraints, performance, and cost-efficiency.

Definitions: Monolithic Sensors Explained

Monolithic sensors are integrated devices that combine multiple sensing components onto a single semiconductor chip, enhancing compactness and signal processing efficiency. Unlike discrete sensors, which consist of separate components assembled together, monolithic sensors reduce parasitic effects and improve reliability by minimizing interconnections. Your choice of monolithic sensors can lead to better performance in applications requiring precise measurements and lower power consumption.

What Are Discrete Sensors?

Discrete sensors detect specific, individual physical events or conditions, such as the presence or absence of an object, often outputting binary signals like on/off states. Unlike monolithic sensors that integrate multiple sensing elements on a single chip, discrete sensors typically consist of separate components tailored for single-function detection. Common examples include limit switches, proximity sensors, and photodetectors used in industrial automation and safety systems.

Core Differences Between Monolithic and Discrete Sensors

Monolithic sensors integrate sensing elements and signal processing circuitry on a single semiconductor chip, resulting in compact size and enhanced reliability. Discrete sensors separate the sensing component from the signal processing units, allowing more flexibility in customization but often increasing size and complexity. Your choice between these sensor types depends on the application's requirements for integration, precision, and space constraints.

Performance Comparison: Accuracy and Reliability

Monolithic sensors integrate sensing elements and processing circuitry on a single chip, enhancing accuracy through reduced signal noise and improved consistency. Discrete sensors, with separate components, may experience increased signal interference, potentially compromising reliability and precision. Industrial applications demanding high accuracy typically favor monolithic sensors due to their superior performance in maintaining consistent measurements over time.

Cost Analysis: Monolithic vs Discrete Sensors

Monolithic sensors generally offer lower overall costs due to integrated manufacturing processes that combine sensing elements and signal processing on a single chip, reducing assembly and packaging expenses. Discrete sensors, while sometimes more customizable, incur higher costs from separate fabrication and more complex assembly steps, increasing material and labor expenses. Cost-efficiency in monolithic sensors is especially evident in high-volume production, where economies of scale significantly reduce per-unit costs compared to discrete sensor approaches.

Application Suitability: Best Use Cases

Monolithic sensors excel in compact, integrated systems such as consumer electronics and automotive applications where space efficiency and cost-effectiveness are crucial. Discrete sensors are preferred in industrial environments requiring high precision and robustness, such as manufacturing process control and environmental monitoring. Choosing between monolithic and discrete sensors depends on factors like required accuracy, environmental conditions, and system integration complexity.

Integration and System Complexity

Monolithic sensors integrate all components into a single chip, significantly reducing system complexity and enhancing reliability by minimizing interconnections. Discrete sensors consist of separate components that require additional assembly and interconnection, leading to increased system size and potential points of failure. Your choice impacts the overall design efficiency, with monolithic solutions offering streamlined integration and simpler system architecture.

Scalability and Maintenance Considerations

Monolithic sensors offer enhanced scalability through their integrated design, enabling easier mass production and consistent performance across devices. Discrete sensors provide greater flexibility for maintenance, allowing individual components to be replaced or upgraded without affecting the entire system. Your choice depends on whether streamlined scalability or customizable maintenance is more critical for your application.

Future Trends in Sensor Technology

Future trends in sensor technology emphasize integrating monolithic sensors with advanced materials and AI for enhanced precision and miniaturization. Discrete sensors continue to evolve through improved interoperability and wireless capabilities, supporting diverse IoT applications. Emerging hybrid sensor systems combine monolithic and discrete elements to optimize performance, energy efficiency, and real-time data processing in industrial and consumer electronics.

Monolithic vs Discrete Sensor Infographic

electrown.com

electrown.com