Fiber optic sensors offer superior resistance to electromagnetic interference and can operate efficiently in hazardous environments, unlike traditional electronic sensors that are more susceptible to noise and signal degradation. Discover how choosing the right sensor technology can enhance Your system's performance by reading the rest of this article.

Table of Comparison

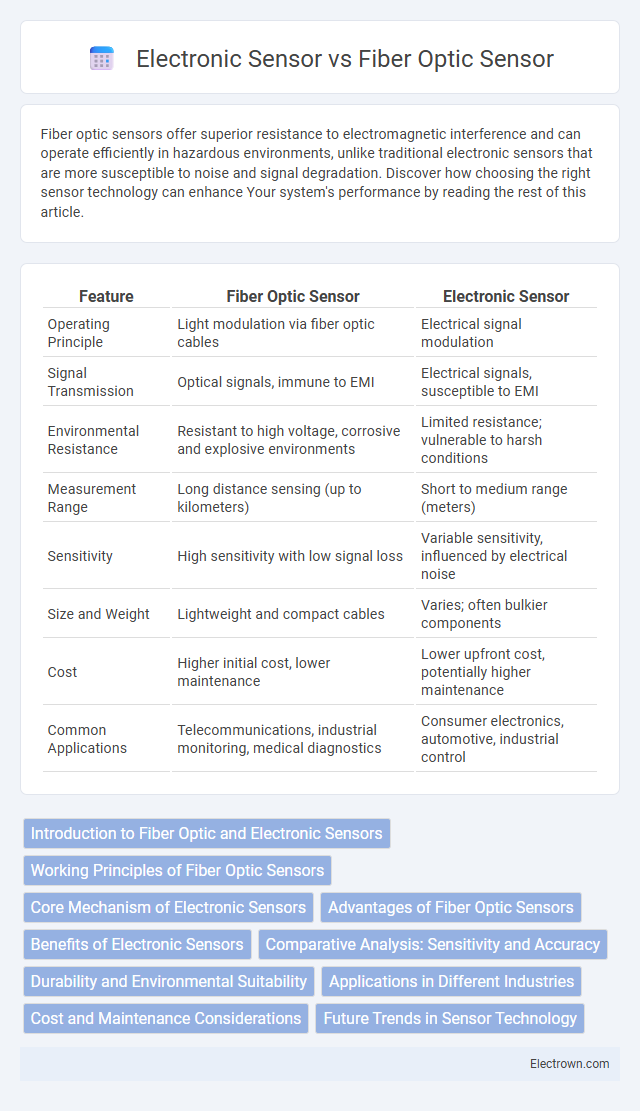

| Feature | Fiber Optic Sensor | Electronic Sensor |

|---|---|---|

| Operating Principle | Light modulation via fiber optic cables | Electrical signal modulation |

| Signal Transmission | Optical signals, immune to EMI | Electrical signals, susceptible to EMI |

| Environmental Resistance | Resistant to high voltage, corrosive and explosive environments | Limited resistance; vulnerable to harsh conditions |

| Measurement Range | Long distance sensing (up to kilometers) | Short to medium range (meters) |

| Sensitivity | High sensitivity with low signal loss | Variable sensitivity, influenced by electrical noise |

| Size and Weight | Lightweight and compact cables | Varies; often bulkier components |

| Cost | Higher initial cost, lower maintenance | Lower upfront cost, potentially higher maintenance |

| Common Applications | Telecommunications, industrial monitoring, medical diagnostics | Consumer electronics, automotive, industrial control |

Introduction to Fiber Optic and Electronic Sensors

Fiber optic sensors utilize light signals transmitted through optical fibers to detect changes in temperature, pressure, or strain with high sensitivity and immunity to electromagnetic interference. Electronic sensors rely on electrical signals to measure physical parameters, providing faster response times but often facing limitations in harsh environments. Your choice depends on application needs, where fiber optic sensors excel in remote or high-voltage settings and electronic sensors offer compact, cost-effective solutions for general use.

Working Principles of Fiber Optic Sensors

Fiber optic sensors operate by transmitting light through optical fibers to detect changes in temperature, strain, pressure, or chemical composition by analyzing variations in light properties such as intensity, phase, polarization, or wavelength. These sensors leverage total internal reflection within the fiber to maintain signal integrity and use interferometric or spectroscopic methods to convert physical changes into measurable optical signals. In contrast to electronic sensors, fiber optic sensors are immune to electromagnetic interference and suitable for harsh environments requiring high sensitivity and precision.

Core Mechanism of Electronic Sensors

Electronic sensors operate by converting physical parameters such as temperature, pressure, or light into electrical signals through mechanisms like piezoelectric, capacitive, or resistive effects. These sensors rely on semiconductor materials or conductive components to detect changes and produce measurable voltage or current variations. The core principle involves transduction of environmental stimuli into electronic data for processing and analysis.

Advantages of Fiber Optic Sensors

Fiber optic sensors offer superior advantages over electronic sensors, including immunity to electromagnetic interference, allowing accurate measurements in electrically noisy environments. They provide high sensitivity and precision for detecting temperature, pressure, and strain changes over long distances with minimal signal loss. Their lightweight, compact design and resistance to harsh environments make them ideal for applications in aerospace, oil and gas, and structural health monitoring.

Benefits of Electronic Sensors

Electronic sensors offer high sensitivity and rapid response times, making them ideal for applications requiring precise and real-time data monitoring. Their versatility allows integration with various digital systems, enhancing automation and control capabilities in industries such as manufacturing and automotive. You benefit from lower initial costs and easier installation compared to fiber optic sensors, facilitating widespread use in everyday electronic devices.

Comparative Analysis: Sensitivity and Accuracy

Fiber optic sensors outperform electronic sensors in sensitivity due to their immunity to electromagnetic interference and ability to detect minute changes in light properties. Accuracy in fiber optic sensors is enhanced by high-resolution signal processing and minimal signal degradation over long distances, which electronic sensors often struggle with due to electrical noise. Your choice between these technologies should consider the specific application requirements for precision and environmental conditions.

Durability and Environmental Suitability

Fiber optic sensors exhibit superior durability and environmental suitability compared to electronic sensors due to their immunity to electromagnetic interference, corrosion resistance, and ability to operate in extreme temperatures and harsh chemical environments. Electronic sensors often face challenges like signal degradation and reduced lifespan when exposed to moisture, high temperatures, or strong electromagnetic fields. Fiber optic technology enables reliable performance in sectors such as oil and gas, aerospace, and industrial automation where robust sensing in demanding conditions is critical.

Applications in Different Industries

Fiber optic sensors excel in industries requiring high precision and immunity to electromagnetic interference, such as aerospace for structural health monitoring and oil and gas for pipeline leak detection. Electronic sensors dominate in consumer electronics and automotive sectors, benefiting from cost-effectiveness and versatility in temperature and pressure measurements. Both sensor types enhance industrial automation and process control but are selected based on environmental conditions and sensitivity requirements.

Cost and Maintenance Considerations

Fiber optic sensors generally have higher initial costs compared to electronic sensors due to advanced materials and installation complexity but offer lower maintenance expenses because of their resistance to electromagnetic interference and harsh environments. Electronic sensors tend to be less expensive upfront but may incur higher long-term maintenance costs due to susceptibility to wear, corrosion, and signal degradation. Choosing between the two depends on the application's environmental conditions, budget constraints, and expected sensor lifespan to optimize total cost of ownership.

Future Trends in Sensor Technology

Fiber optic sensors are poised to dominate future sensor technology due to their immunity to electromagnetic interference, high sensitivity, and capability for remote sensing in harsh environments. Advances in photonic integration and nanomaterials are expected to enhance the accuracy and miniaturization of fiber optic sensors, making them ideal for applications in smart infrastructure, medical diagnostics, and autonomous systems. Electronic sensors will continue to evolve with improved power efficiency and AI-driven data processing but may face limitations compared to fiber optics in environments requiring high precision and durability.

Fiber Optic Sensor vs Electronic Sensor Infographic

electrown.com

electrown.com