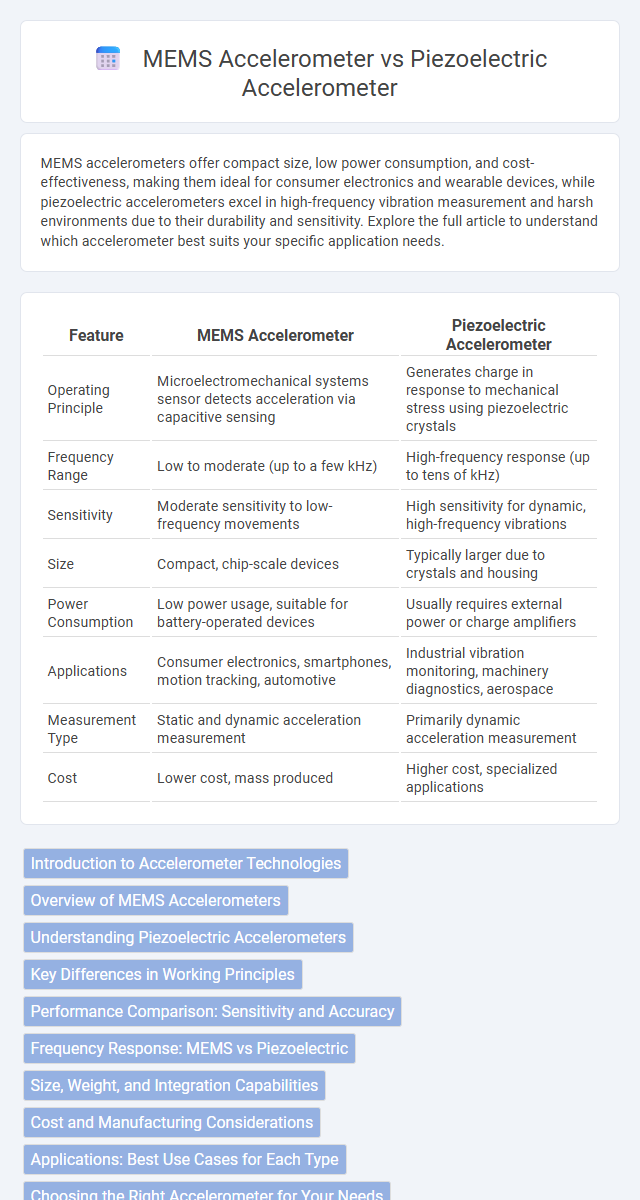

MEMS accelerometers offer compact size, low power consumption, and cost-effectiveness, making them ideal for consumer electronics and wearable devices, while piezoelectric accelerometers excel in high-frequency vibration measurement and harsh environments due to their durability and sensitivity. Explore the full article to understand which accelerometer best suits your specific application needs.

Table of Comparison

| Feature | MEMS Accelerometer | Piezoelectric Accelerometer |

|---|---|---|

| Operating Principle | Microelectromechanical systems sensor detects acceleration via capacitive sensing | Generates charge in response to mechanical stress using piezoelectric crystals |

| Frequency Range | Low to moderate (up to a few kHz) | High-frequency response (up to tens of kHz) |

| Sensitivity | Moderate sensitivity to low-frequency movements | High sensitivity for dynamic, high-frequency vibrations |

| Size | Compact, chip-scale devices | Typically larger due to crystals and housing |

| Power Consumption | Low power usage, suitable for battery-operated devices | Usually requires external power or charge amplifiers |

| Applications | Consumer electronics, smartphones, motion tracking, automotive | Industrial vibration monitoring, machinery diagnostics, aerospace |

| Measurement Type | Static and dynamic acceleration measurement | Primarily dynamic acceleration measurement |

| Cost | Lower cost, mass produced | Higher cost, specialized applications |

Introduction to Accelerometer Technologies

MEMS accelerometers utilize microelectromechanical systems to measure acceleration by detecting changes in capacitance between moving and fixed structures, offering compact size and low power consumption ideal for consumer electronics and IoT devices. In contrast, piezoelectric accelerometers generate an electrical charge proportional to mechanical stress on piezoelectric materials, making them highly sensitive and suitable for high-frequency vibration analysis in industrial applications. Your choice depends on the specific sensitivity, frequency response, and environmental conditions required for accurate motion sensing or vibration monitoring.

Overview of MEMS Accelerometers

MEMS accelerometers utilize microelectromechanical systems technology to detect acceleration through microscopic mechanical structures built on a semiconductor chip, enabling compact size and low power consumption. These sensors offer high sensitivity and can measure static and dynamic accelerations, making them ideal for applications ranging from consumer electronics to automotive safety systems. MEMS accelerometers provide robust performance with integrated signal processing, supporting precise motion sensing and vibration analysis in various environments.

Understanding Piezoelectric Accelerometers

Piezoelectric accelerometers utilize the piezoelectric effect, where certain materials generate an electric charge in response to mechanical stress, enabling precise vibration and impact measurements. Unlike MEMS accelerometers, which rely on microfabricated structures and capacitance changes, piezoelectric sensors offer high-frequency response and excellent sensitivity for dynamic applications. Your choice depends on the need for measuring static or low-frequency accelerations where MEMS excels, versus high-frequency, shock, and vibration environments suited for piezoelectric accelerometers.

Key Differences in Working Principles

MEMS accelerometers utilize microelectromechanical systems technology with capacitive sensing to detect changes in position caused by acceleration, converting mechanical movement into an electrical signal. Piezoelectric accelerometers rely on the piezoelectric effect, where certain crystals generate an electric charge in response to mechanical stress from acceleration forces. Your choice depends on factors like frequency range and sensitivity, as MEMS excel in low-frequency, static measurements, while piezoelectric sensors are better suited for high-frequency, dynamic applications.

Performance Comparison: Sensitivity and Accuracy

MEMS accelerometers offer high sensitivity and accuracy in low-frequency, low-amplitude vibrations, making them ideal for consumer electronics and wearable devices. Piezoelectric accelerometers excel in high-frequency response and dynamic range, providing precise measurements in industrial and automotive applications. Understanding these performance differences helps you select the best sensor for your specific sensitivity and accuracy requirements.

Frequency Response: MEMS vs Piezoelectric

MEMS accelerometers typically offer a wide frequency response range from DC up to 10 kHz, making them suitable for low-frequency and static acceleration measurements. Piezoelectric accelerometers excel in high-frequency applications, often extending from 1 Hz to over 100 kHz, ideal for vibration and dynamic event detection. Your choice depends on whether you need accurate static readings with MEMS or high-frequency dynamic response with piezoelectric sensors.

Size, Weight, and Integration Capabilities

MEMS accelerometers are compact, lightweight devices typically measuring a few millimeters, making them ideal for seamless integration into portable electronics and wearable technology. In contrast, piezoelectric accelerometers, though often larger and heavier, offer higher sensitivity and durability, which suits industrial and high-performance applications. Your choice depends on prioritizing miniaturization and system integration versus enhanced measurement capabilities.

Cost and Manufacturing Considerations

MEMS accelerometers offer lower production costs due to batch fabrication using semiconductor manufacturing techniques, making them ideal for high-volume applications. Piezoelectric accelerometers involve more complex materials and assembly processes, leading to higher manufacturing expenses and limited scalability. Your choice depends on budget constraints and production volume requirements.

Applications: Best Use Cases for Each Type

MEMS accelerometers excel in consumer electronics, automotive airbag systems, and wearable devices due to their low cost, compact size, and low power consumption, making them ideal for continuous motion tracking and vibration monitoring. Piezoelectric accelerometers are best suited for industrial machinery diagnostics, aerospace structural health monitoring, and high-frequency vibration analysis where high sensitivity, wide frequency response, and durability under harsh conditions are critical. Choosing between MEMS and piezoelectric accelerometers depends on factors such as frequency range, environmental robustness, and accuracy requirements specific to each application.

Choosing the Right Accelerometer for Your Needs

MEMS accelerometers excel in compact size, low power consumption, and cost-effectiveness, making them ideal for consumer electronics and wearable devices, while piezoelectric accelerometers provide superior sensitivity and high-frequency response suited for industrial vibration analysis and structural health monitoring. Consider your application's frequency range, environment, and sensitivity requirements to determine the appropriate technology. Your choice hinges on balancing accuracy, durability, and budget to ensure optimal performance.

MEMS Accelerometer vs Piezoelectric Accelerometer Infographic

electrown.com

electrown.com