Rogowski coils offer accurate, non-intrusive AC current measurement with wide bandwidth and no saturation issues, while Hall sensors provide direct current measurement including DC but may suffer from temperature drift and lower frequency response. Discover how choosing between these sensors can impact your electrical measurement needs by reading the rest of the article.

Table of Comparison

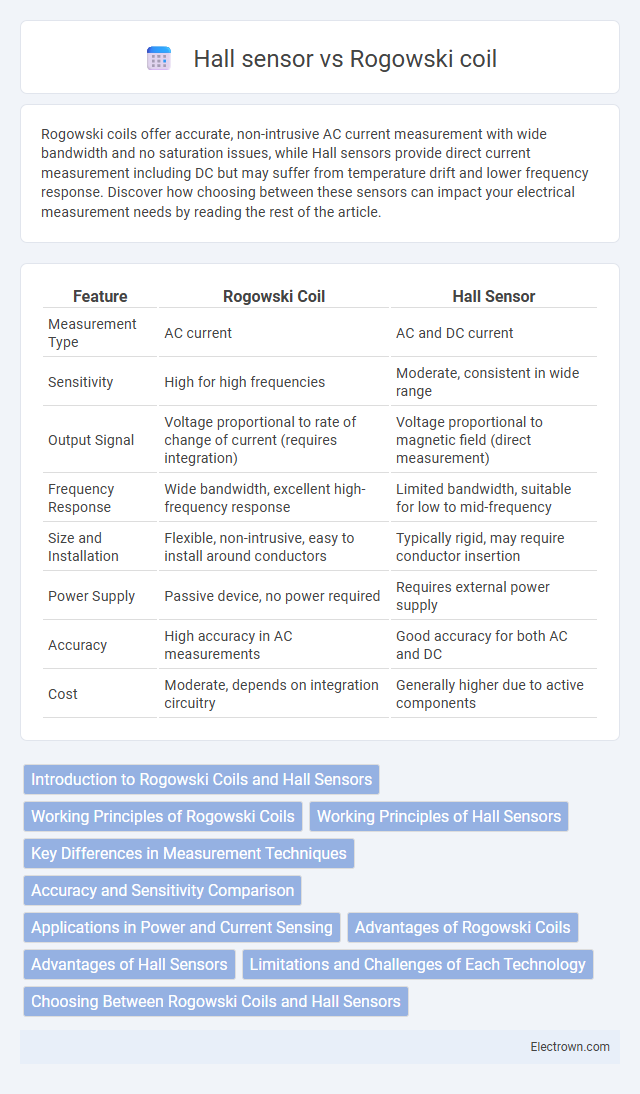

| Feature | Rogowski Coil | Hall Sensor |

|---|---|---|

| Measurement Type | AC current | AC and DC current |

| Sensitivity | High for high frequencies | Moderate, consistent in wide range |

| Output Signal | Voltage proportional to rate of change of current (requires integration) | Voltage proportional to magnetic field (direct measurement) |

| Frequency Response | Wide bandwidth, excellent high-frequency response | Limited bandwidth, suitable for low to mid-frequency |

| Size and Installation | Flexible, non-intrusive, easy to install around conductors | Typically rigid, may require conductor insertion |

| Power Supply | Passive device, no power required | Requires external power supply |

| Accuracy | High accuracy in AC measurements | Good accuracy for both AC and DC |

| Cost | Moderate, depends on integration circuitry | Generally higher due to active components |

Introduction to Rogowski Coils and Hall Sensors

Rogowski coils measure alternating current by detecting the magnetic field around a conductor with a flexible, air-cored coil, providing high accuracy and wide bandwidth without saturation. Hall sensors use the Hall effect to detect magnetic fields, offering direct current measurement and compact size ideal for low to medium current applications. Your choice between these sensors depends on factors such as current range, frequency response, and installation constraints.

Working Principles of Rogowski Coils

Rogowski coils operate based on the principle of electromagnetic induction, where a coil wrapped around a conductor detects the time-varying magnetic field generated by the alternating current flowing through the conductor. Unlike Hall sensors that measure magnetic fields directly via the Hall effect, Rogowski coils produce an output voltage proportional to the rate of change of current, requiring integration to obtain the actual current waveform. Your choice between these sensors depends on factors like frequency range, linearity, and ease of installation, with Rogowski coils excelling in high-frequency current measurement and non-intrusive applications.

Working Principles of Hall Sensors

Hall sensors operate based on the Hall effect, where a voltage is generated perpendicular to the current flow and magnetic field in a conductor. When exposed to a magnetic field, the Hall sensor produces a voltage proportional to the magnetic flux density, enabling accurate current measurement. This principle allows Hall sensors to measure both AC and DC currents without direct electrical contact, making them versatile for various applications.

Key Differences in Measurement Techniques

Rogowski coils measure alternating current by detecting the magnetic field generated around a conductor through a flexible, air-cored coil, providing accurate, non-intrusive current measurement without saturation. Hall sensors directly measure the magnetic flux density using a semiconductor element, enabling both AC and DC current detection with a compact form factor. Your choice depends on the application's need for frequency range, linearity, and installation constraints, with Rogowski coils excelling in high-frequency AC measurement and Hall sensors offering versatility for DC and low-frequency currents.

Accuracy and Sensitivity Comparison

Rogowski coils offer high accuracy in measuring alternating currents without saturation, making them ideal for large current ranges but are less sensitive to low-frequency signals compared to Hall sensors. Hall sensors provide high sensitivity and can detect both AC and DC currents, but their accuracy can be affected by temperature variations and magnetic interference. For applications demanding precise measurement of transient currents, Rogowski coils outperform in accuracy, whereas Hall sensors excel in sensitivity and versatility.

Applications in Power and Current Sensing

Rogowski coils excel in measuring high-frequency alternating currents and transient currents, making them ideal for power quality analysis and fault detection in electrical grids. Hall sensors provide accurate DC and low-frequency AC current measurements, widely used in battery management systems, electric vehicles, and industrial motor control. Your choice depends on whether accurate analysis of dynamic current waveforms or consistent DC current measurement is required.

Advantages of Rogowski Coils

Rogowski coils offer superior linearity and frequency response compared to Hall sensors, making them ideal for accurately measuring high-frequency and transient currents. Their lightweight and flexible design enables easy installation around conductors without interrupting the circuit, unlike rigid Hall sensors. Moreover, Rogowski coils do not saturate under high current conditions, ensuring reliable measurements in power monitoring and fault detection applications.

Advantages of Hall Sensors

Hall sensors offer direct measurement of magnetic fields with excellent linearity and sensitivity, making them ideal for precise current sensing in various applications. They provide galvanic isolation without the need for additional components, enhancing safety and integration in compact designs. Your system benefits from their ability to detect both AC and DC currents, unlike Rogowski coils, which are limited to AC measurements.

Limitations and Challenges of Each Technology

Rogowski coils face limitations in measuring low-frequency or DC currents due to their reliance on induced voltage that requires integration, which can introduce drift and noise errors. Hall sensors encounter challenges such as sensitivity to temperature variations and magnetic hysteresis, leading to reduced accuracy in fluctuating or harsh environmental conditions. Both technologies require careful calibration and compensation techniques to mitigate these issues for precise current measurement applications.

Choosing Between Rogowski Coils and Hall Sensors

Choosing between Rogowski coils and Hall sensors depends on your specific application requirements such as measurement range, accuracy, and installation constraints. Rogowski coils excel in measuring high AC currents with excellent linearity and no saturation but require integrators for signal processing. Hall sensors provide direct measurement of DC and AC currents with compact designs but may suffer from drift and limited bandwidth compared to Rogowski coils.

Rogowski coil vs Hall sensor Infographic

electrown.com

electrown.com