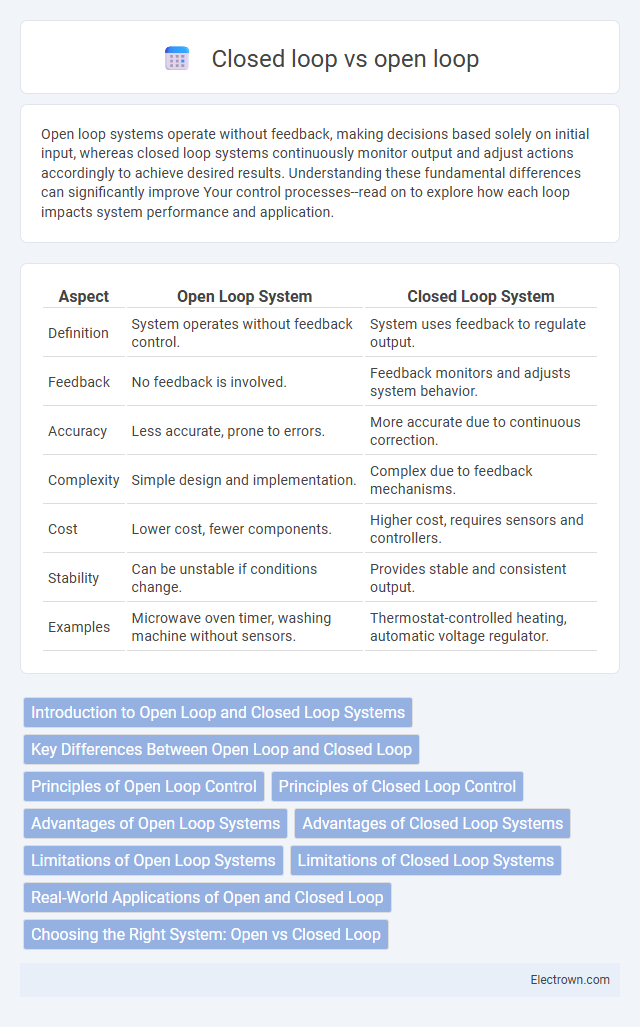

Open loop systems operate without feedback, making decisions based solely on initial input, whereas closed loop systems continuously monitor output and adjust actions accordingly to achieve desired results. Understanding these fundamental differences can significantly improve Your control processes--read on to explore how each loop impacts system performance and application.

Table of Comparison

| Aspect | Open Loop System | Closed Loop System |

|---|---|---|

| Definition | System operates without feedback control. | System uses feedback to regulate output. |

| Feedback | No feedback is involved. | Feedback monitors and adjusts system behavior. |

| Accuracy | Less accurate, prone to errors. | More accurate due to continuous correction. |

| Complexity | Simple design and implementation. | Complex due to feedback mechanisms. |

| Cost | Lower cost, fewer components. | Higher cost, requires sensors and controllers. |

| Stability | Can be unstable if conditions change. | Provides stable and consistent output. |

| Examples | Microwave oven timer, washing machine without sensors. | Thermostat-controlled heating, automatic voltage regulator. |

Introduction to Open Loop and Closed Loop Systems

Open loop systems operate without feedback, executing predetermined instructions regardless of output variations, making them simpler but less adaptive. Closed loop systems continuously monitor output through feedback to adjust inputs, enhancing accuracy and stability in processes such as temperature control or automated machinery. Understanding whether your application benefits from real-time adjustments or straightforward control determines the optimal system choice.

Key Differences Between Open Loop and Closed Loop

Open loop systems operate without feedback, executing predefined commands regardless of output changes, whereas closed loop systems continuously monitor output and adjust inputs to maintain desired performance. Open loop designs are simpler and cost-effective but less accurate, while closed loop designs provide higher precision and stability through feedback control. Key differences include responsiveness, complexity, and error correction capabilities, with closed loop systems excelling in dynamic environments requiring consistent adjustment.

Principles of Open Loop Control

Open loop control operates on predetermined input signals without feedback from the system's output, relying solely on the initial control action for functionality. It is commonly used in applications where the relationship between input and output is well-defined and disturbances are minimal, such as simple heating systems or timed motors. The principle centers on executing commands without adjustment based on system response, leading to faster operation but less accuracy compared to closed loop control.

Principles of Closed Loop Control

Closed loop control operates by continuously monitoring the output and comparing it to the desired setpoint, using feedback to adjust inputs and reduce errors. Key principles include feedback measurement, error detection, and corrective action, ensuring system stability and accuracy in dynamic environments. This method contrasts with open loop control, which lacks feedback and cannot self-correct deviations.

Advantages of Open Loop Systems

Open loop systems offer simplicity and cost-effectiveness by operating without feedback mechanisms, reducing complexity in design and maintenance. They provide faster response times since control actions are executed without waiting for system output measurements. These systems are ideal for processes where the relationship between input and output is well-understood and consistent, minimizing the risk of instability or oscillations.

Advantages of Closed Loop Systems

Closed loop systems offer superior accuracy and stability by continuously monitoring output and adjusting inputs to maintain desired performance. These systems reduce errors and improve efficiency, making them ideal for applications requiring precise control such as automation and robotics. You benefit from enhanced reliability and responsiveness compared to open loop systems that operate without feedback.

Limitations of Open Loop Systems

Open loop systems lack feedback mechanisms, which causes them to be unable to correct errors or adapt to changing environmental conditions, leading to lower accuracy and reliability. These systems are limited in dynamic environments because they cannot compensate for disturbances or variations in system parameters. Consequently, open loop control is often unsuitable for applications requiring precision and real-time adjustments.

Limitations of Closed Loop Systems

Closed loop systems face limitations such as complexity in design and higher costs due to the need for sensors and feedback components. They may experience stability issues and delayed responses when the feedback loop introduces lag. Your control applications might also suffer from reduced performance in noisy or unpredictable environments where sensor accuracy is compromised.

Real-World Applications of Open and Closed Loop

Open loop systems are widely used in applications such as microwave ovens and washing machines, where the input commands drive preset operations without feedback monitoring. Closed loop systems dominate in automotive cruise control and industrial robotics, utilizing sensors to continuously adjust processes for precision and adaptability. This feedback mechanism in closed loop systems enhances performance and responsiveness in dynamic real-world environments.

Choosing the Right System: Open vs Closed Loop

Choosing the right control system depends on the application's precision and feedback requirements. Open loop systems operate without feedback, making them simpler and cost-effective but less accurate in dynamic environments. Closed loop systems use real-time feedback to adjust operations, offering higher accuracy and adaptability, ideal for processes where precision and error correction are critical.

Open loop vs closed loop Infographic

electrown.com

electrown.com