A cold solder joint occurs when the solder doesn't melt completely, resulting in a weak, unreliable connection prone to failure, while a hot solder joint is formed by properly heating the components to create a strong, durable bond essential for optimal electrical performance. Understanding the differences between these solder joints is crucial for maintaining the integrity of your electronic repairs and projects; continue reading to learn how to identify and fix each type.

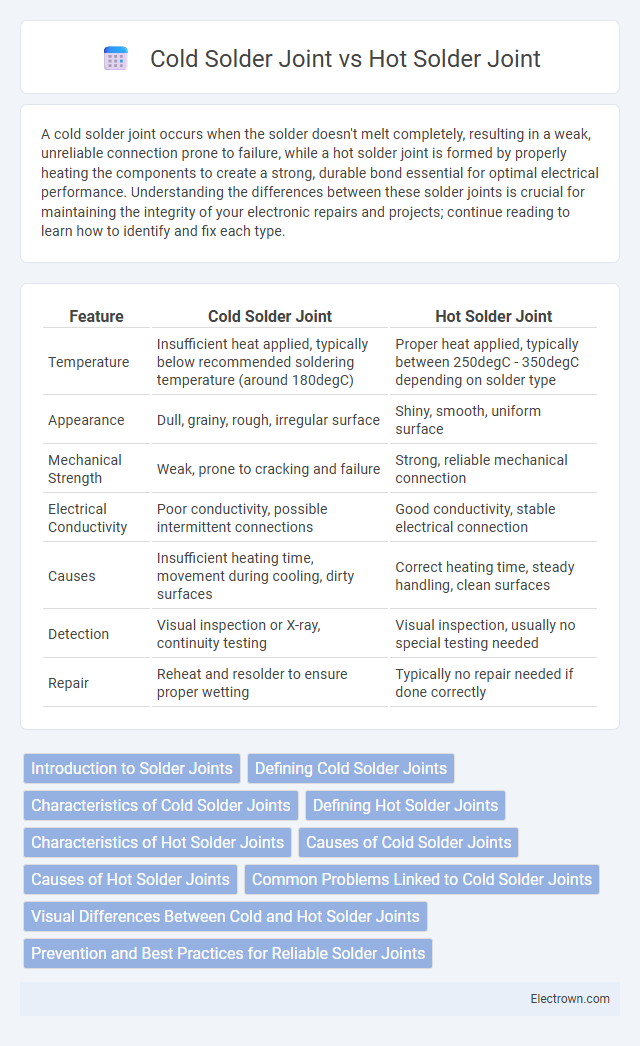

Table of Comparison

| Feature | Cold Solder Joint | Hot Solder Joint |

|---|---|---|

| Temperature | Insufficient heat applied, typically below recommended soldering temperature (around 180degC) | Proper heat applied, typically between 250degC - 350degC depending on solder type |

| Appearance | Dull, grainy, rough, irregular surface | Shiny, smooth, uniform surface |

| Mechanical Strength | Weak, prone to cracking and failure | Strong, reliable mechanical connection |

| Electrical Conductivity | Poor conductivity, possible intermittent connections | Good conductivity, stable electrical connection |

| Causes | Insufficient heating time, movement during cooling, dirty surfaces | Correct heating time, steady handling, clean surfaces |

| Detection | Visual inspection or X-ray, continuity testing | Visual inspection, usually no special testing needed |

| Repair | Reheat and resolder to ensure proper wetting | Typically no repair needed if done correctly |

Introduction to Solder Joints

Solder joints are critical electrical connections formed by melting solder to join metal components, ensuring mechanical stability and conductivity in electronic assemblies. Cold solder joints occur when the solder fails to properly melt or adhere, resulting in weak, brittle connections prone to failure. Hot solder joints, by contrast, are formed with adequate heat, creating strong, reliable bonds essential for optimal circuit performance.

Defining Cold Solder Joints

A cold solder joint occurs when the solder fails to melt completely, leading to a weak, unreliable electrical connection prone to cracking and intermittent failures. This defect is often caused by insufficient heat or poor technique during the soldering process, resulting in a grainy or dull appearance. Identifying and avoiding cold solder joints is essential to ensure the durability and conductivity of your electronic assemblies.

Characteristics of Cold Solder Joints

Cold solder joints are characterized by a dull, grainy, or cracked appearance, often resulting in poor electrical conductivity and mechanical strength. These joints typically occur when the solder fails to melt properly or when the components move before the solder solidifies. Your electronic device's reliability can be compromised due to intermittent connections caused by cold solder joints, leading to potential circuit failures.

Defining Hot Solder Joints

Hot solder joints occur when the soldering iron is applied at the correct temperature, allowing the solder to melt and flow smoothly for a reliable electrical connection. These joints are characterized by a shiny, smooth surface indicative of proper heat application and good wetting between the solder and components. Your electronic repairs benefit from hot solder joints as they ensure strong mechanical strength and optimal conductivity, reducing the risk of circuit failure.

Characteristics of Hot Solder Joints

Hot solder joints exhibit a smooth, shiny surface and strong mechanical strength due to proper heating during the soldering process. They ensure a reliable electrical connection with minimal resistance and enhance the durability of the joint under thermal and mechanical stress. These joints demonstrate excellent wetting on both the solder pad and component lead, preventing cold solder joint defects such as cracks and brittle bonds.

Causes of Cold Solder Joints

Cold solder joints occur primarily due to insufficient heat during the soldering process, causing poor metal bonding and resulting in a weak electrical connection. Factors such as using a low-temperature soldering iron, moving components before the solder solidifies, or applying solder to oxidized surfaces contribute to these defects. Ensuring proper temperature control and clean surfaces is essential to prevent cold solder joints and maintain reliable circuit performance.

Causes of Hot Solder Joints

Hot solder joints primarily result from excessive heat applied during soldering, causing the solder to become oxidized and form a dull, brittle connection. Prolonged contact with a high-temperature soldering iron can degrade the flux, reducing its ability to clean and bond the metals effectively. Inconsistent heating or using a soldering iron with a temperature above the recommended range also contributes to poor wetting and weak mechanical strength in hot solder joints.

Common Problems Linked to Cold Solder Joints

Cold solder joints often cause poor electrical conductivity and intermittent connections due to insufficient heating during the soldering process. These joints may appear dull or grainy and are prone to cracking, which can lead to circuit failures and unreliable performance in electronic devices. Ensuring proper soldering temperature and technique helps you avoid the common problems associated with cold solder joints.

Visual Differences Between Cold and Hot Solder Joints

Cold solder joints typically display a dull, grainy, or cracked surface with gaps or unevenness, indicating poor metal-to-metal bonding. Hot solder joints, in contrast, exhibit a shiny, smooth, and uniform appearance, reflecting proper heat application and strong electrical connection. Visual inspection of these characteristics is crucial for identifying solder joint quality and ensuring reliable electronic performance.

Prevention and Best Practices for Reliable Solder Joints

Preventing cold solder joints involves maintaining proper soldering iron temperature between 350degC and 400degC to ensure adequate heat transfer and thorough wetting of the components. Best practices include using quality solder with appropriate flux, cleaning surfaces before soldering, and applying consistent pressure during soldering to avoid poor electrical connections and mechanical failure. Regular inspection with magnification and testing for continuity help ensure reliable solder joints, reducing the risk of intermittent faults and enhancing circuit durability.

Cold Solder Joint vs Hot Solder Joint Infographic

electrown.com

electrown.com