Capacitive loads store energy in an electric field and cause current to lead voltage, while inductive loads store energy in a magnetic field and cause current to lag voltage, affecting power factor and system efficiency. Understanding these differences is crucial for optimizing Your electrical system performance; continue reading to explore their impacts in detail.

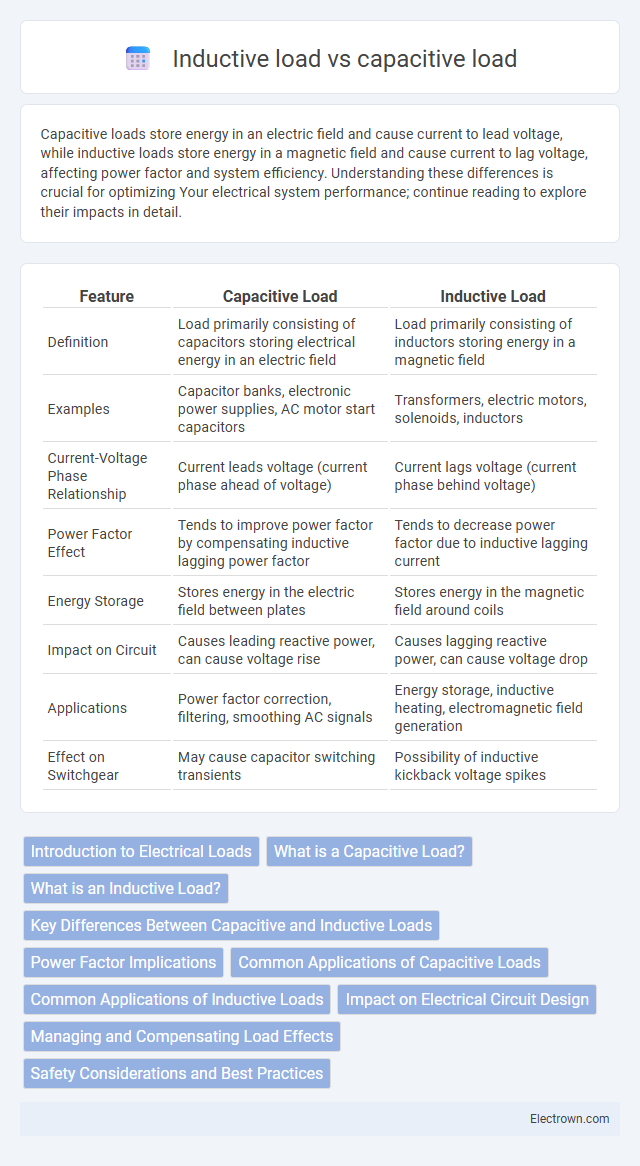

Table of Comparison

| Feature | Capacitive Load | Inductive Load |

|---|---|---|

| Definition | Load primarily consisting of capacitors storing electrical energy in an electric field | Load primarily consisting of inductors storing energy in a magnetic field |

| Examples | Capacitor banks, electronic power supplies, AC motor start capacitors | Transformers, electric motors, solenoids, inductors |

| Current-Voltage Phase Relationship | Current leads voltage (current phase ahead of voltage) | Current lags voltage (current phase behind voltage) |

| Power Factor Effect | Tends to improve power factor by compensating inductive lagging power factor | Tends to decrease power factor due to inductive lagging current |

| Energy Storage | Stores energy in the electric field between plates | Stores energy in the magnetic field around coils |

| Impact on Circuit | Causes leading reactive power, can cause voltage rise | Causes lagging reactive power, can cause voltage drop |

| Applications | Power factor correction, filtering, smoothing AC signals | Energy storage, inductive heating, electromagnetic field generation |

| Effect on Switchgear | May cause capacitor switching transients | Possibility of inductive kickback voltage spikes |

Introduction to Electrical Loads

Electrical loads are classified based on their impedance characteristics, with capacitive loads storing energy in an electric field and inductive loads storing energy in a magnetic field. Capacitive loads, such as capacitor banks and certain electronic devices, cause current to lead voltage, improving power factor in AC circuits. Inductive loads, including transformers, motors, and reactors, cause current to lag voltage, often resulting in decreased power factor and increased reactive power demand.

What is a Capacitive Load?

A capacitive load stores energy in an electric field created between its plates, causing current to lead voltage in the circuit. Common examples include capacitor banks and certain types of power factor correction devices. Understanding your capacitive load is essential for accurate power management and minimizing reactive power issues in electrical systems.

What is an Inductive Load?

An inductive load is an electrical component that primarily stores energy in a magnetic field when current flows through it, typically found in devices such as motors, transformers, and coils. This type of load causes the current to lag behind the voltage, resulting in phase difference and reactive power consumption. Understanding inductive load characteristics is essential for accurate power factor correction and efficient energy management in AC circuits.

Key Differences Between Capacitive and Inductive Loads

Capacitive loads store energy in an electric field and cause current to lead voltage, while inductive loads store energy in a magnetic field and cause current to lag voltage. Key differences lie in their phase relationships, reactive power characteristics, and impact on power factor correction in your electrical systems. Understanding these distinctions helps optimize energy efficiency and equipment performance in circuits involving capacitive or inductive components.

Power Factor Implications

Capacitive loads cause leading power factors by supplying reactive power, which can offset the lagging reactive power from inductive loads and improve overall system efficiency. Inductive loads, such as motors and transformers, create lagging power factors that reduce the effective power available and increase losses in electrical systems. Understanding the power factor implications of capacitive versus inductive loads helps you optimize energy consumption and reduce utility penalties associated with poor power factor.

Common Applications of Capacitive Loads

Capacitive loads are widely used in applications such as power factor correction in electrical power systems, where capacitor banks help improve the efficiency of power delivery by offsetting inductive effects from motors and transformers. They are also common in electronic devices like timing circuits, oscillator circuits, and filters that require the storage and release of electric charge. Your equipment benefits from capacitive loads when precise voltage regulation and energy-saving power management are essential.

Common Applications of Inductive Loads

Inductive loads, such as electric motors, transformers, and solenoids, are commonly used in industrial machinery, HVAC systems, and power distribution networks. These loads generate magnetic fields and often cause phase shifts between voltage and current, impacting power factor and energy efficiency. Understanding how your inductive load affects your electrical system helps optimize performance and reduce potential issues related to reactive power.

Impact on Electrical Circuit Design

Capacitive loads cause leading current and voltage phase shifts, which affect power factor and may require power factor correction devices in electrical circuit design. Inductive loads generate lagging current and magnetic fields that necessitate considerations for voltage drops, reactive power compensation, and potential inrush currents to prevent circuit malfunction. Designing circuits must account for these differing effects to ensure stability, efficiency, and protection of components in alternating current (AC) power systems.

Managing and Compensating Load Effects

Managing capacitive load effects involves minimizing voltage rise and reducing power factor distortion through the use of reactive power compensators like capacitors or synchronous condensers. Inductive load compensation requires addressing voltage drop and lagging power factor by installing power factor correction equipment such as capacitor banks or active filters. Your effective load management strategy should balance these techniques to ensure system stability, improve efficiency, and reduce energy costs.

Safety Considerations and Best Practices

Capacitive loads can cause voltage spikes and resonance, requiring proper snubber circuits and surge protection devices to ensure safety. Inductive loads generate high inrush currents and back EMF, necessitating the use of flyback diodes or varistors to prevent damage to switching components. Implementing correct grounding, insulation, and adherence to manufacturer specifications minimizes risks associated with these loads in electrical systems.

Capacitive load vs inductive load Infographic

electrown.com

electrown.com