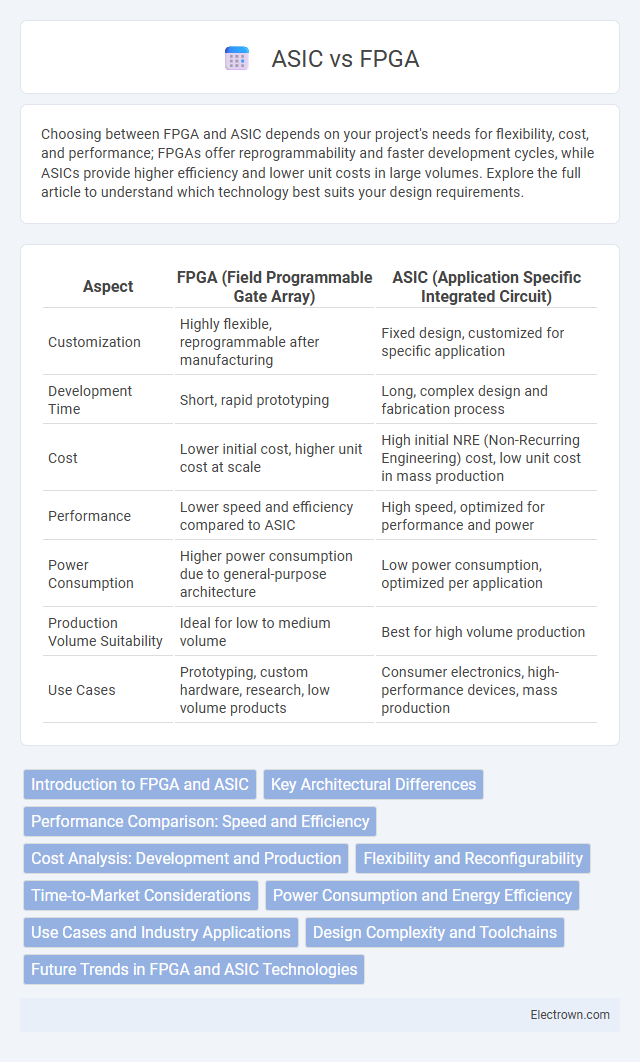

Choosing between FPGA and ASIC depends on your project's needs for flexibility, cost, and performance; FPGAs offer reprogrammability and faster development cycles, while ASICs provide higher efficiency and lower unit costs in large volumes. Explore the full article to understand which technology best suits your design requirements.

Table of Comparison

| Aspect | FPGA (Field Programmable Gate Array) | ASIC (Application Specific Integrated Circuit) |

|---|---|---|

| Customization | Highly flexible, reprogrammable after manufacturing | Fixed design, customized for specific application |

| Development Time | Short, rapid prototyping | Long, complex design and fabrication process |

| Cost | Lower initial cost, higher unit cost at scale | High initial NRE (Non-Recurring Engineering) cost, low unit cost in mass production |

| Performance | Lower speed and efficiency compared to ASIC | High speed, optimized for performance and power |

| Power Consumption | Higher power consumption due to general-purpose architecture | Low power consumption, optimized per application |

| Production Volume Suitability | Ideal for low to medium volume | Best for high volume production |

| Use Cases | Prototyping, custom hardware, research, low volume products | Consumer electronics, high-performance devices, mass production |

Introduction to FPGA and ASIC

Field-Programmable Gate Arrays (FPGAs) are integrated circuits designed for post-manufacturing configuration, enabling rapid prototyping and hardware customization. Application-Specific Integrated Circuits (ASICs) are custom-designed chips optimized for a specific task, offering superior performance and energy efficiency compared to general-purpose hardware. While FPGAs provide flexibility and shorter development cycles, ASICs deliver higher speed and lower unit cost in large-scale production.

Key Architectural Differences

FPGA architecture features a matrix of configurable logic blocks (CLBs) with programmable interconnects, allowing for flexible hardware customization, while ASICs are designed with fixed, application-specific logic circuits optimized for performance and power efficiency. FPGAs use lookup tables (LUTs) and flip-flops to implement diverse functions, enabling rapid prototyping and reprogramming, whereas ASICs rely on dedicated gates and standard cells tailored for a single optimized function. Your design choice impacts scalability, speed, and production costs due to these fundamental architectural differences.

Performance Comparison: Speed and Efficiency

FPGA and ASIC differ significantly in speed and efficiency, with ASICs offering superior performance due to their custom-designed hardware tailored for specific tasks, resulting in faster processing and lower power consumption. FPGAs provide flexibility and reconfigurability but generally exhibit slower speeds and higher energy usage compared to ASICs because of their programmable logic architecture. Your choice between FPGA and ASIC should weigh the need for peak performance against adaptability and development cost.

Cost Analysis: Development and Production

FPGA development costs are lower due to reusable hardware and faster prototyping, making them ideal for small to medium production runs. ASICs require significant upfront investment in design and manufacturing tools, with higher non-recurring engineering (NRE) costs that become cost-effective only at large-scale production volumes. Production expenses for FPGAs remain relatively stable per unit, whereas ASIC per-unit costs decrease substantially with volume, justifying the initial development expenditure.

Flexibility and Reconfigurability

FPGAs (Field-Programmable Gate Arrays) offer superior flexibility and reconfigurability compared to ASICs (Application-Specific Integrated Circuits) by allowing hardware designs to be updated and customized post-manufacturing. This adaptability makes FPGAs ideal for rapid prototyping, iterative development, and applications requiring frequent updates or modifications. In contrast, ASICs provide fixed functionality optimized for performance and power efficiency but lack the ability to be reprogrammed after fabrication.

Time-to-Market Considerations

FPGA offers significantly faster time-to-market compared to ASIC due to its reprogrammable nature, allowing rapid prototyping and design iterations without the lengthy fabrication process. ASIC development involves extensive design validation and fabrication cycles that can extend over several months, making it less suitable for projects with tight deadlines. Your choice between FPGA and ASIC should consider how critical speed-to-market is for your product deployment and competitive advantage.

Power Consumption and Energy Efficiency

FPGA devices typically consume more power than ASICs due to their reconfigurable architecture, which introduces additional overhead in logic and routing blocks. ASICs offer superior energy efficiency by tailoring circuits specifically for the intended application, minimizing dynamic and static power consumption. If power consumption is a critical factor in Your design, choosing an ASIC can significantly enhance energy efficiency and reduce operational costs.

Use Cases and Industry Applications

FPGA technology excels in prototyping, telecommunications, and adaptable computing environments where flexibility and rapid reconfiguration are crucial, whereas ASICs dominate high-volume consumer electronics, automotive, and medical devices due to their optimized performance and cost-efficiency. Industries like aerospace, defense, and data centers leverage FPGAs for customizable, real-time processing, while ASICs are preferred in smartphones and cryptocurrency mining for their speed and energy efficiency. Your choice between FPGA and ASIC hinges on application requirements, production scale, and the need for design flexibility versus tailored performance.

Design Complexity and Toolchains

FPGA design complexity centers on configuring pre-built logic blocks using hardware description languages (HDLs) and leveraging vendor-specific toolchains like Xilinx Vivado or Intel Quartus, which offer rapid prototyping and iterative development. ASIC design involves intricate custom circuit design requiring extensive verification, synthesis, and fabrication steps supported by comprehensive EDA toolchains such as Synopsys Design Compiler and Cadence Innovus, demanding higher expertise and longer development cycles. Toolchain selection impacts optimization capabilities, with FPGA tools emphasizing flexibility and reprogrammability, while ASIC toolchains focus on performance, power, and area efficiency through custom silicon implementation.

Future Trends in FPGA and ASIC Technologies

Future trends in FPGA technology emphasize increased integration of AI and machine learning capabilities, with advancements in heterogeneous computing combining FPGA fabric with dedicated processors to enhance performance and power efficiency. ASIC developments focus on specialized chips for high-performance applications such as 5G, autonomous vehicles, and blockchain, optimizing for speed, energy efficiency, and miniaturization through advanced CMOS process nodes below 5nm. The convergence of FPGA and ASIC technologies is emerging, with adaptive SoCs blending programmable logic with fixed-function ASIC blocks to deliver flexible yet high-efficiency solutions across diverse industries.

FPGA vs ASIC Infographic

electrown.com

electrown.com