SPI offers higher data transfer rates and simpler hardware implementation, making it ideal for applications requiring fast communication and full-duplex data exchange. Understanding the differences and advantages of SPI versus I2C can help optimize your device connectivity; explore the full article to learn which protocol suits your project best.

Table of Comparison

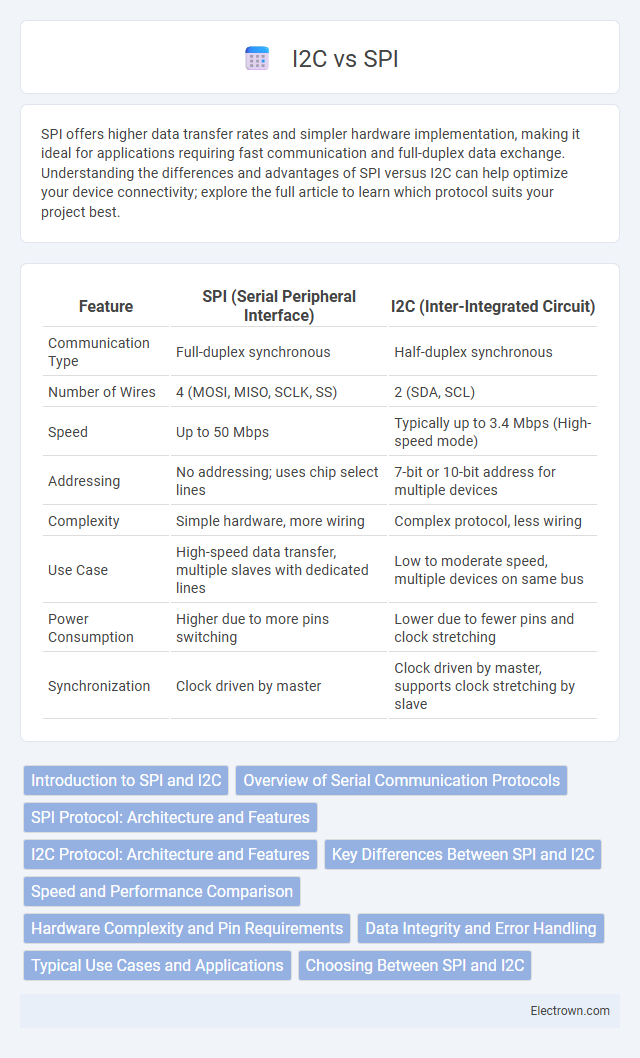

| Feature | SPI (Serial Peripheral Interface) | I2C (Inter-Integrated Circuit) |

|---|---|---|

| Communication Type | Full-duplex synchronous | Half-duplex synchronous |

| Number of Wires | 4 (MOSI, MISO, SCLK, SS) | 2 (SDA, SCL) |

| Speed | Up to 50 Mbps | Typically up to 3.4 Mbps (High-speed mode) |

| Addressing | No addressing; uses chip select lines | 7-bit or 10-bit address for multiple devices |

| Complexity | Simple hardware, more wiring | Complex protocol, less wiring |

| Use Case | High-speed data transfer, multiple slaves with dedicated lines | Low to moderate speed, multiple devices on same bus |

| Power Consumption | Higher due to more pins switching | Lower due to fewer pins and clock stretching |

| Synchronization | Clock driven by master | Clock driven by master, supports clock stretching by slave |

Introduction to SPI and I2C

SPI (Serial Peripheral Interface) and I2C (Inter-Integrated Circuit) are two widely-used communication protocols in embedded systems designed for connecting microcontrollers to peripherals. SPI operates with a master-slave architecture using separate lines for data transmission, clock, and chip select, providing high-speed data exchange ideal for applications needing fast and reliable communication. I2C uses a multi-master, multi-slave setup with only two bidirectional lines (SDA and SCL), efficient for simpler, lower-speed connections where reducing wiring complexity and supporting multiple devices on the same bus is essential for your design.

Overview of Serial Communication Protocols

SPI (Serial Peripheral Interface) and I2C (Inter-Integrated Circuit) are widely used serial communication protocols in embedded systems, enabling efficient data exchange between microcontrollers and peripheral devices. SPI operates with a full-duplex master-slave architecture using separate clock, data input, and data output lines, offering high-speed data transfer with low latency. I2C employs a multi-master, multi-slave single-wire bus design with two lines (SDA and SCL), supporting addressable communication and simplicity for connecting multiple devices with moderate speed.

SPI Protocol: Architecture and Features

The SPI protocol employs a master-slave architecture featuring separate lines for data transmission (MOSI), data reception (MISO), clock (SCLK), and chip select (CS), enabling full-duplex communication and faster data transfer rates than I2C. Characterized by simplicity and high-speed capabilities, SPI supports multiple slave devices through individual chip select signals without requiring address arbitration. This architecture eliminates bus contention and reduces latency, making SPI ideal for applications demanding rapid, reliable data exchange such as memory cards and display controllers.

I2C Protocol: Architecture and Features

The I2C protocol features a two-wire serial communication architecture consisting of a Serial Data Line (SDA) and a Serial Clock Line (SCL), enabling multiple master and slave devices on the same bus. It employs addressing to identify slave devices uniquely, supporting 7-bit and 10-bit address modes for flexible device communication. I2C supports multi-master arbitration, clock stretching, and bidirectional data flow, making it ideal for short-distance intra-board communication with moderate speed requirements ranging from 100 kbps (Standard mode) to 3.4 Mbps (High-Speed mode).

Key Differences Between SPI and I2C

SPI (Serial Peripheral Interface) offers higher data transfer speeds with full-duplex communication and uses multiple wires, typically including separate lines for clock, data in, data out, and chip select. I2C (Inter-Integrated Circuit) operates with a two-wire interface using serial data (SDA) and serial clock (SCL) lines, supporting multiple devices with unique addresses over a simpler bus topology. SPI requires more pins and does not include built-in addressing, while I2C allows multiple masters and slaves through addressing but has slower data rates and half-duplex communication.

Speed and Performance Comparison

SPI offers significantly higher data transfer rates, typically reaching speeds up to 50 Mbps or more, compared to I2C's maximum standard speed of 3.4 Mbps in High-Speed mode. The full-duplex capability of SPI enables simultaneous sending and receiving of data, enhancing overall system performance, while I2C operates in half-duplex mode, which can introduce communication delays. Your choice between SPI and I2C depends on whether speed and real-time data throughput are critical for your application or if simpler wiring and addressing take precedence.

Hardware Complexity and Pin Requirements

SPI communication requires more pins than I2C, typically using four lines: MOSI, MISO, SCLK, and SS, which increases hardware complexity but allows for faster data transfer and full duplex communication. I2C uses only two wires, SDA and SCL, minimizing pin count and simplifying hardware design, making it ideal for devices with limited pin availability. The lower pin requirements of I2C come at the cost of slower speeds and half-duplex communication compared to SPI.

Data Integrity and Error Handling

SPI offers higher data integrity due to its full-duplex communication and dedicated clock line, reducing the likelihood of data corruption compared to I2C's half-duplex and shared bus architecture. Error detection in I2C is facilitated by the acknowledgment (ACK) and not-acknowledgment (NACK) bits after each byte, enabling basic error handling, whereas SPI lacks inherent error checking mechanisms, relying on external protocols for validation. The simplicity of SPI enhances speed and reliability in environments demanding robust data integrity, while I2C's built-in acknowledgment provides minimal error feedback suitable for less critical applications.

Typical Use Cases and Applications

SPI is typically used in applications requiring high-speed data transfer and precise synchronization, such as flash memory, sensors, and display modules. I2C is favored for multi-device communication on short-distance, low-speed buses in embedded systems, including temperature sensors, EEPROMs, and real-time clocks. Your choice depends on the need for speed, complexity of wiring, and the number of connected peripherals.

Choosing Between SPI and I2C

Choosing between SPI and I2C depends on specific project requirements such as speed, complexity, and device count. SPI offers higher data transfer speeds and full-duplex communication, making it ideal for applications needing fast and continuous data exchange. I2C provides a simpler two-wire interface with multi-master support and easy device addressing, which is better suited for complex networks with multiple devices at lower speeds.

SPI vs I2C Infographic

electrown.com

electrown.com