In-circuit programming (ICP) involves programming a microcontroller while it is placed on the circuit board, allowing direct access to the microcontroller's pins through a dedicated programming interface. Understanding the differences between ICP and in-system programming (ISP) can help you choose the best method for your development needs, so explore the rest of this article for a detailed comparison.

Table of Comparison

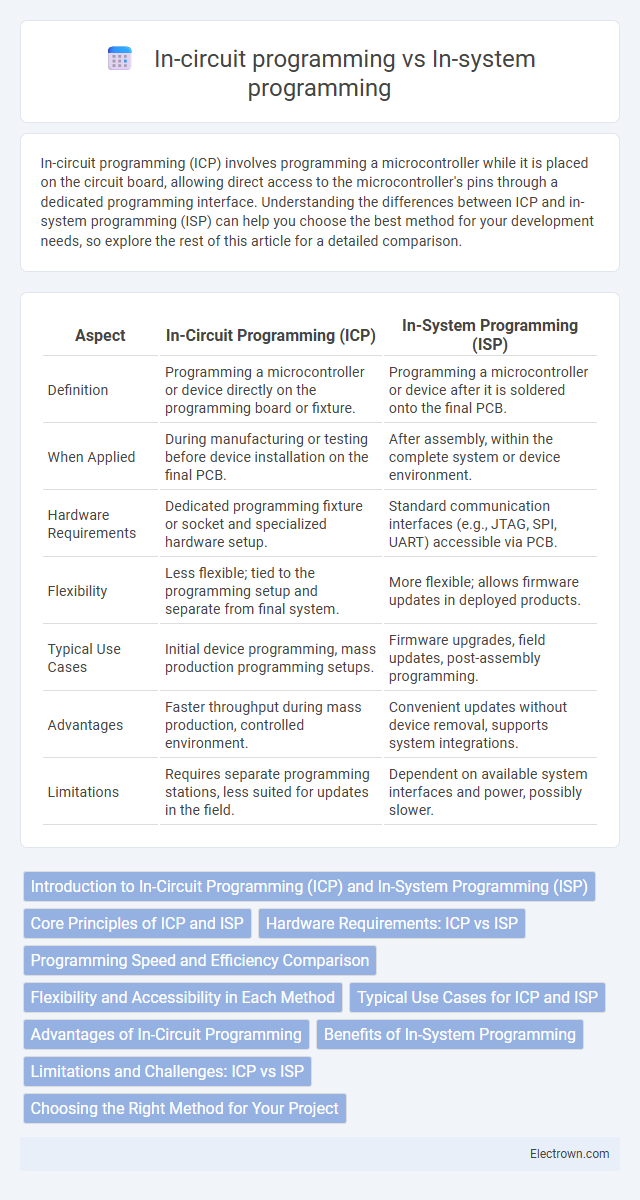

| Aspect | In-Circuit Programming (ICP) | In-System Programming (ISP) |

|---|---|---|

| Definition | Programming a microcontroller or device directly on the programming board or fixture. | Programming a microcontroller or device after it is soldered onto the final PCB. |

| When Applied | During manufacturing or testing before device installation on the final PCB. | After assembly, within the complete system or device environment. |

| Hardware Requirements | Dedicated programming fixture or socket and specialized hardware setup. | Standard communication interfaces (e.g., JTAG, SPI, UART) accessible via PCB. |

| Flexibility | Less flexible; tied to the programming setup and separate from final system. | More flexible; allows firmware updates in deployed products. |

| Typical Use Cases | Initial device programming, mass production programming setups. | Firmware upgrades, field updates, post-assembly programming. |

| Advantages | Faster throughput during mass production, controlled environment. | Convenient updates without device removal, supports system integrations. |

| Limitations | Requires separate programming stations, less suited for updates in the field. | Dependent on available system interfaces and power, possibly slower. |

Introduction to In-Circuit Programming (ICP) and In-System Programming (ISP)

In-Circuit Programming (ICP) refers to the method of programming microcontrollers or integrated circuits directly on the circuit board using dedicated programming interfaces and tools, enabling firmware updates without removing the chip. In-System Programming (ISP) allows programming or reprogramming of microcontrollers embedded within a system through standardized communication protocols like JTAG or SPI, which facilitates debugging and firmware enhancement during system operation. Both ICP and ISP technologies are essential for efficient firmware development and maintenance in embedded systems, with ICP emphasizing physical connection methods and ISP focusing on in-built communication channels.

Core Principles of ICP and ISP

In-circuit programming (ICP) involves directly connecting the programming device to the microcontroller's programming pins while the chip is still mounted on the PCB, enabling code upload without socketing. In-system programming (ISP) expands on this by allowing firmware updates through a communication interface such as SPI, JTAG, or UART, facilitating flexible and remote programming within the operational system. Understanding these core principles helps you choose the right method for efficient firmware deployment and debugging in embedded system development.

Hardware Requirements: ICP vs ISP

In-circuit programming (ICP) requires a dedicated programmer device connected to the microcontroller's programming pins, often involving socket adapters or specialized hardware for direct access during manufacturing or development. In-system programming (ISP) enables programming of microcontrollers or devices directly on the final circuit board using standard communication interfaces like SPI, JTAG, or UART without removing the chip. ISP hardware requirements are typically simpler, relying on existing interfaces and minimal additional circuitry, making it more flexible and cost-effective for field updates and mass production.

Programming Speed and Efficiency Comparison

In-circuit programming (ICP) typically offers faster programming speeds due to direct access to the microcontroller's pins without the need for additional interface circuitry, enhancing your development efficiency. In-system programming (ISP) provides greater flexibility by allowing programming through a standard communication interface such as UART or SPI, which may introduce slightly slower speeds but supports easier updates and debugging in deployed systems. Choosing between ICP and ISP depends on balancing your priority for programming speed against the convenience of on-site device programming and reconfiguration.

Flexibility and Accessibility in Each Method

In-circuit programming (ICP) offers greater flexibility by allowing direct access to a microcontroller's pins on a dedicated programming interface, facilitating easier debugging and rapid firmware updates during development. In-system programming (ISP) enhances accessibility by enabling firmware updates without removing the chip from the end product, supporting remote and field firmware modifications through standard communication protocols like UART, SPI, or JTAG. ICP is preferred for prototyping due to precise control and signal integrity, whereas ISP excels in production and maintenance environments by reducing handling risks and improving update convenience.

Typical Use Cases for ICP and ISP

In-circuit programming (ICP) is commonly used during the manufacturing phase to program microcontrollers directly on the PCB, enabling rapid firmware updates without removing the chip. In-system programming (ISP) offers flexibility for field updates and debugging, allowing You to reprogram devices already installed within a system or product without specialized equipment. Both methods optimize development and maintenance workflows but are chosen based on whether programming occurs pre- or post-deployment.

Advantages of In-Circuit Programming

In-circuit programming (ICP) offers significant advantages such as real-time debugging and immediate firmware updates without removing the microcontroller from the board. It enables precise control over the programming process, reducing development cycle times and minimizing the risk of hardware damage during firmware installation. ICP also supports boundary-scan testing, improving overall system reliability and simplifying fault diagnosis.

Benefits of In-System Programming

In-system programming (ISP) enables firmware updates directly on a microcontroller within a fully assembled device, eliminating the need for chip removal or specialized programming hardware. This method reduces production costs and time by allowing rapid deployment of software patches and functional improvements during manufacturing or field servicing. Enhanced flexibility and convenience in ISP significantly improve product lifecycle management and support dynamic development cycles.

Limitations and Challenges: ICP vs ISP

In-circuit programming (ICP) faces limitations such as the need for physical access to specific programming pins, which can be difficult in densely packed PCBs, while in-system programming (ISP) allows programming through standard interfaces without removing the chip from the system. ICP challenges include potential damage during contact and signal interference, whereas ISP struggles with firmware security restrictions and power supply dependencies. Your choice between ICP and ISP hinges on balancing ease of access, risk of hardware damage, and the flexibility of remote firmware updates within your development environment.

Choosing the Right Method for Your Project

In-circuit programming (ICP) offers direct access to microcontrollers on the development board, enabling fast debugging and firmware updates without removing chips, ideal for prototypes and small-scale projects. In-system programming (ISP) allows programming devices within the final hardware setup, essential for mass production and embedded systems with limited physical access. Evaluating your project's scale, hardware configuration, and update frequency helps determine whether ICP's flexibility or ISP's convenience better suits your development needs.

In-circuit programming vs in-system programming Infographic

electrown.com

electrown.com