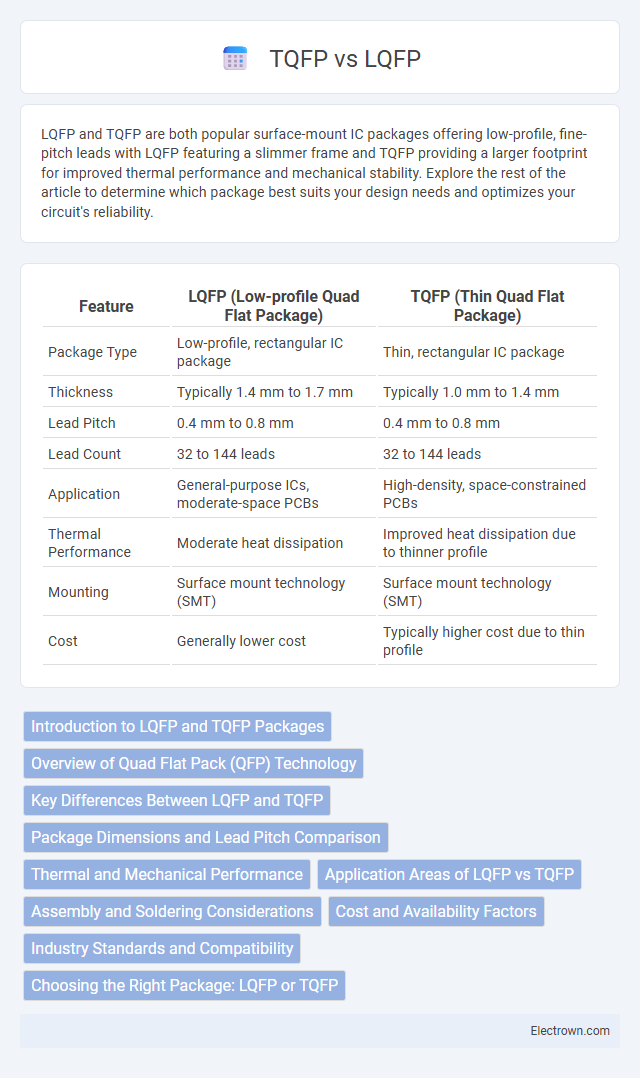

LQFP and TQFP are both popular surface-mount IC packages offering low-profile, fine-pitch leads with LQFP featuring a slimmer frame and TQFP providing a larger footprint for improved thermal performance and mechanical stability. Explore the rest of the article to determine which package best suits your design needs and optimizes your circuit's reliability.

Table of Comparison

| Feature | LQFP (Low-profile Quad Flat Package) | TQFP (Thin Quad Flat Package) |

|---|---|---|

| Package Type | Low-profile, rectangular IC package | Thin, rectangular IC package |

| Thickness | Typically 1.4 mm to 1.7 mm | Typically 1.0 mm to 1.4 mm |

| Lead Pitch | 0.4 mm to 0.8 mm | 0.4 mm to 0.8 mm |

| Lead Count | 32 to 144 leads | 32 to 144 leads |

| Application | General-purpose ICs, moderate-space PCBs | High-density, space-constrained PCBs |

| Thermal Performance | Moderate heat dissipation | Improved heat dissipation due to thinner profile |

| Mounting | Surface mount technology (SMT) | Surface mount technology (SMT) |

| Cost | Generally lower cost | Typically higher cost due to thin profile |

Introduction to LQFP and TQFP Packages

LQFP (Low-Profile Quad Flat Package) and TQFP (Thin Quad Flat Package) are popular surface-mount IC packaging types designed for high-density PCB layouts. LQFP features a low-profile design with lead pitches typically ranging from 0.5mm to 1.0mm, making it suitable for applications requiring compact size and thermal efficiency. TQFP offers a thinner, lightweight package with finer lead pitches, often used in devices where space saving and weight reduction are critical to your electronic design.

Overview of Quad Flat Pack (QFP) Technology

Quad Flat Pack (QFP) technology features surface-mount IC packages with leads extending from all four sides, optimizing board space and improving thermal performance. Low-profile Quad Flat Package (LQFP) variants offer a thinner profile compared to standard Thin Quad Flat Package (TQFP), making LQFP ideal for applications requiring compact and lightweight designs. Both LQFP and TQFP maintain consistent pin pitches typically ranging from 0.4mm to 0.8mm, supporting high pin counts and precise soldering processes in advanced PCB assemblies.

Key Differences Between LQFP and TQFP

LQFP (Low-profile Quad Flat Package) features a thinner body height compared to TQFP (Thin Quad Flat Package), making it ideal for space-constrained applications where a low profile is critical. While both packages offer similar lead pitch and pin counts, TQFP generally provides better thermal dissipation due to its slightly thicker substrate, enhancing heat management in high-power circuits. Your choice between LQFP and TQFP depends on the balance needed between component height constraints and thermal performance requirements.

Package Dimensions and Lead Pitch Comparison

LQFP (Low-profile Quad Flat Package) typically features smaller package dimensions and a tighter lead pitch, often around 0.4mm, compared to TQFP's (Thin Quad Flat Package) lead pitch of 0.5mm or greater, resulting in a more compact footprint for high-density applications. The reduced height of LQFP makes it suitable for space-constrained designs, whereas TQFP packages generally offer easier soldering and repair due to their slightly larger lead spacing. Your choice between LQFP and TQFP depends on balancing board space efficiency with manufacturing and assembly considerations.

Thermal and Mechanical Performance

LQFP (Low-profile Quad Flat Package) and TQFP (Thin Quad Flat Package) differ significantly in thermal and mechanical performance, with LQFP providing enhanced heat dissipation due to its thicker body and larger thermal pad area. TQFP offers better mechanical resilience in compact designs thanks to its thinner profile, reducing stress on PCB solder joints during thermal cycling. Thermal resistance in LQFP packages typically ranges between 30-50 degC/W, while TQFP may exhibit slightly higher values, influencing their suitability for high-power applications and thermal management strategies.

Application Areas of LQFP vs TQFP

LQFP packages are commonly used in consumer electronics, automotive control systems, and communication devices where moderate pin counts and compact size are essential for efficient circuit design. TQFP packages find their application in high-performance microcontrollers, FPGA modules, and industrial automation due to their enhanced thermal dissipation and reliability in complex circuit environments. Choosing between LQFP and TQFP depends on your project's requirements for pin density, thermal management, and mechanical robustness.

Assembly and Soldering Considerations

LQFP (Low-Profile Quad Flat Package) and TQFP (Thin Quad Flat Package) differ primarily in thickness, impacting assembly and soldering processes. LQFP's lower profile reduces the risk of solder bridging during reflow, making it suitable for automated soldering on PCBs with tight vertical space constraints. Your choice between LQFP and TQFP affects thermal management and inspection ease, with TQFP generally allowing better heat dissipation but requiring careful alignment to prevent tombstoning during soldering.

Cost and Availability Factors

LQFP (Low-Profile Quad Flat Package) generally offers lower manufacturing costs due to its simpler package structure and smaller size, making it suitable for high-volume, cost-sensitive applications. TQFP (Thin Quad Flat Package) often incurs higher costs because of its thinner and more complex design, which can improve thermal performance and signal integrity but requires more advanced fabrication processes. Availability tends to be broader for LQFP components, as they are widely used in consumer electronics, whereas TQFP variants may have more limited options but are preferred in applications demanding better electrical characteristics.

Industry Standards and Compatibility

LQFP (Low-profile Quad Flat Package) and TQFP (Thin Quad Flat Package) are widely accepted industry standards for surface-mount integrated circuits, ensuring broad compatibility with automated assembly processes and PCB layouts. Differences in body thickness and lead pitch influence the choice between LQFP and TQFP based on space constraints and thermal performance in your electronic designs. Compatibility with existing manufacturing equipment and component footprints makes both packages versatile options in embedded systems and consumer electronics.

Choosing the Right Package: LQFP or TQFP

Choosing between LQFP (Low-profile Quad Flat Package) and TQFP (Thin Quad Flat Package) depends on the specific application requirements such as PCB space constraints, thermal management, and assembly complexity. LQFP offers a lower profile and easier handling in automated assembly while TQFP provides thinner dimensions suitable for space-limited designs requiring minimal height. Careful evaluation of device pin count, heat dissipation, and manufacturing capabilities ensures optimal package selection for improved performance and reliability.

LQFP vs TQFP Infographic

electrown.com

electrown.com