Planar transformers feature a flat, compact design ideal for high-frequency applications, offering better thermal management and lower electromagnetic interference compared to the bulkier, traditional toroidal transformers known for their efficient magnetic flux containment and low core losses. Discover which transformer suits Your specific needs by exploring the detailed comparison in the rest of this article.

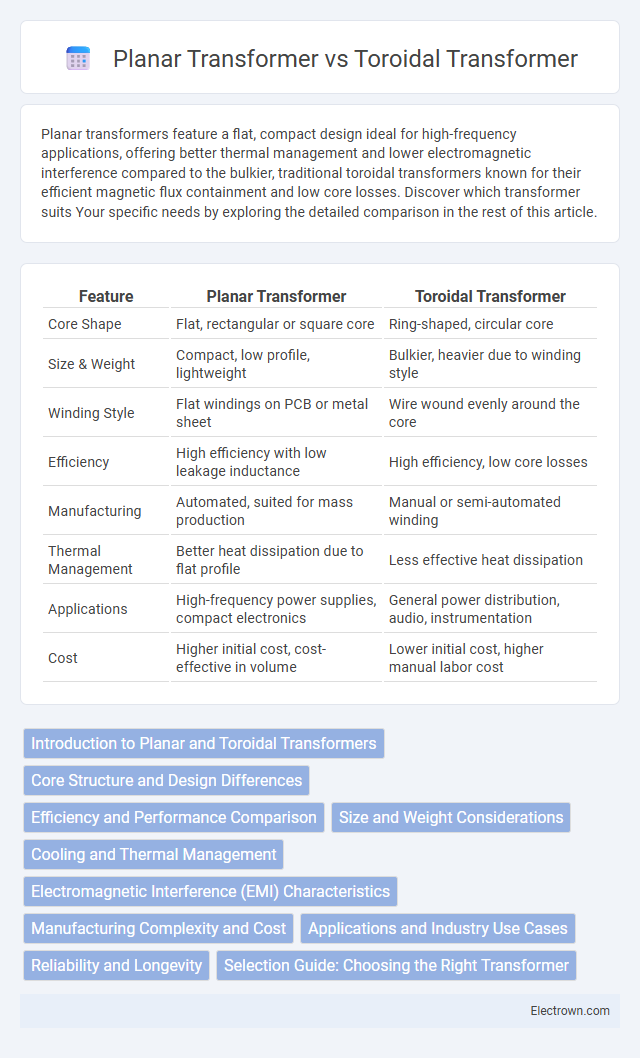

Table of Comparison

| Feature | Planar Transformer | Toroidal Transformer |

|---|---|---|

| Core Shape | Flat, rectangular or square core | Ring-shaped, circular core |

| Size & Weight | Compact, low profile, lightweight | Bulkier, heavier due to winding style |

| Winding Style | Flat windings on PCB or metal sheet | Wire wound evenly around the core |

| Efficiency | High efficiency with low leakage inductance | High efficiency, low core losses |

| Manufacturing | Automated, suited for mass production | Manual or semi-automated winding |

| Thermal Management | Better heat dissipation due to flat profile | Less effective heat dissipation |

| Applications | High-frequency power supplies, compact electronics | General power distribution, audio, instrumentation |

| Cost | Higher initial cost, cost-effective in volume | Lower initial cost, higher manual labor cost |

Introduction to Planar and Toroidal Transformers

Planar transformers use flat, layered windings on printed circuit boards, offering compact size and improved thermal performance compared to traditional wound coils. Toroidal transformers feature a doughnut-shaped magnetic core that provides high efficiency, low electromagnetic interference, and reduced audible noise. Your choice between these transformers depends on application requirements such as space constraints, power density, and electromagnetic compatibility.

Core Structure and Design Differences

Planar transformers feature a flat, layered core structure typically made from ferrite or laminated steel, optimizing space and heat dissipation for high-frequency applications. Toroidal transformers use a continuous ring-shaped core, usually constructed from grain-oriented silicon steel, which minimizes core losses and electromagnetic interference due to its closed-loop magnetic path. The planar design enables compact, low-profile integration on printed circuit boards, whereas the toroidal design offers superior efficiency and reduced audible noise in power conversion systems.

Efficiency and Performance Comparison

Planar transformers offer higher efficiency and better performance than traditional toroidal transformers due to their low profile, reduced winding resistance, and improved thermal management. Their compact design enables faster switching speeds and lower leakage inductance, which enhances overall power conversion efficiency in high-frequency applications. Your choice of a planar transformer can lead to significant energy savings and improved reliability in compact electronic devices.

Size and Weight Considerations

Planar transformers typically offer a smaller footprint and reduced weight compared to toroidal transformers due to their flat, layered construction that enables compact integration within PCB assemblies. Toroidal transformers, while efficient, tend to be bulkier and heavier because of their wound coil design on a doughnut-shaped core, which increases volume and mass. These size and weight differences make planar transformers preferable for applications requiring high power density and space savings, such as in modern power supplies and medical devices.

Cooling and Thermal Management

Planar transformers offer superior cooling and thermal management due to their flat, compact design, which allows for better heat dissipation across a larger surface area compared to toroidal transformers. Toroidal transformers rely on their doughnut-shaped core, which can concentrate heat and require additional cooling measures such as heat sinks or forced air. Optimizing your device's efficiency and lifespan becomes easier with planar transformers because their enhanced thermal performance reduces hotspots and the risk of overheating.

Electromagnetic Interference (EMI) Characteristics

Planar transformers typically exhibit lower Electromagnetic Interference (EMI) due to their flat, layered design that minimizes parasitic inductance and capacitance, resulting in reduced noise emissions. Toroidal transformers, while compact and efficient with a closed magnetic path, can generate higher EMI levels because their wire winding can produce stray magnetic fields. Your choice between these types should consider EMI sensitivity requirements in your application, with planar transformers offering superior EMI performance for high-frequency switching environments.

Manufacturing Complexity and Cost

Planar transformers exhibit lower manufacturing complexity due to their flat, laminated construction that allows for automated production and integration into printed circuit boards, significantly reducing assembly time and labor costs. In contrast, toroidal transformers require intricate winding processes around a doughnut-shaped core, involving more manual labor and specialized equipment, resulting in higher production costs. The streamlined design of planar transformers also promotes miniaturization and consistent quality, making them more cost-effective for high-volume electronic applications compared to the traditional toroidal models.

Applications and Industry Use Cases

Planar transformers are extensively used in high-frequency, compact power supplies for telecommunications, aerospace, and medical devices, offering efficient thermal management and reduced electromagnetic interference. Toroidal transformers find primary applications in audio equipment, power conditioning, and renewable energy systems due to their low magnetic leakage and high efficiency in handling high power loads. Industries such as automotive and industrial automation prefer planar transformers for space-constrained designs, while toroidal transformers dominate in energy-sensitive applications requiring minimal noise and high reliability.

Reliability and Longevity

Planar transformers offer enhanced reliability and longevity due to their compact, low-profile design, which reduces thermal and mechanical stress compared to traditional toroidal transformers. Their advanced manufacturing process ensures consistent winding precision and superior heat dissipation, extending the operational lifespan. Choosing a planar transformer for your application can result in improved durability and reduced maintenance costs over time.

Selection Guide: Choosing the Right Transformer

Planar transformers offer a compact, low-profile design ideal for high-frequency applications and automated manufacturing, making them suitable for modern power electronics where space and efficiency are critical. Toroidal transformers excel in low-noise, high-efficiency power delivery with superior magnetic flux containment, preferred in audio equipment and industrial power supplies requiring minimal electromagnetic interference. Selection depends on application-specific requirements such as size constraints, thermal management, frequency range, and electromagnetic compatibility to optimize performance and reliability.

Planar transformer vs toroidal transformer Infographic

electrown.com

electrown.com