Bulkhead connectors provide secure, pass-through connections by mounting directly through a panel or enclosure, ensuring robust mechanical stability and ease of access from both sides. Understanding the differences and appropriate applications for bulkhead connectors versus panel mount connectors can help you choose the best component for your device's connectivity needs; explore the detailed comparison in the rest of this article.

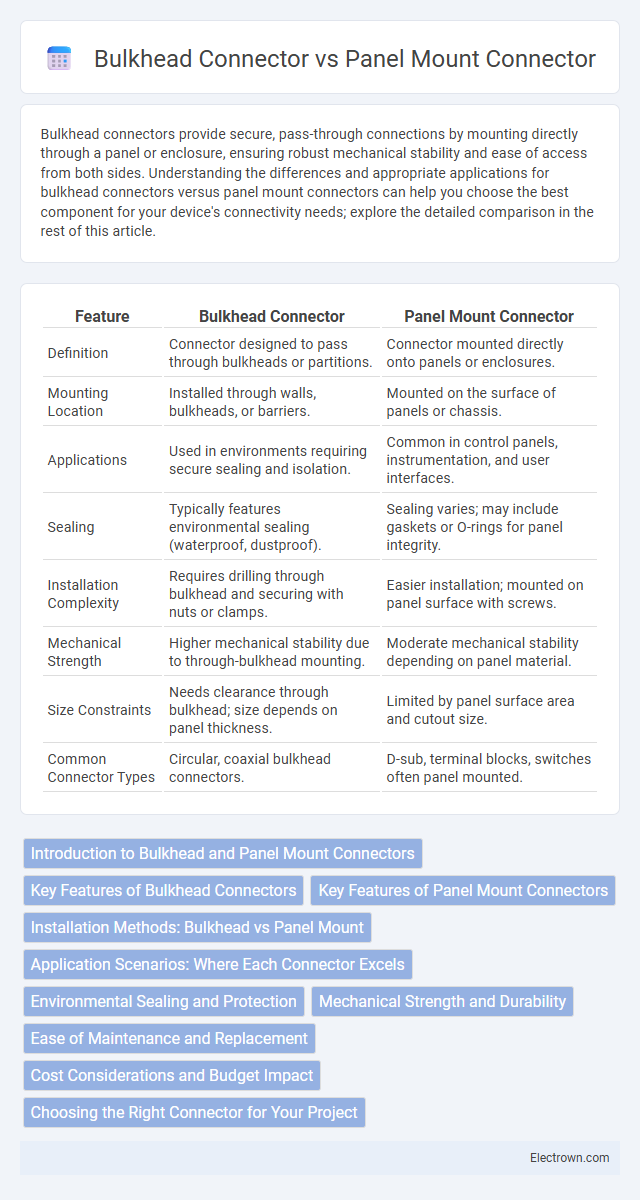

Table of Comparison

| Feature | Bulkhead Connector | Panel Mount Connector |

|---|---|---|

| Definition | Connector designed to pass through bulkheads or partitions. | Connector mounted directly onto panels or enclosures. |

| Mounting Location | Installed through walls, bulkheads, or barriers. | Mounted on the surface of panels or chassis. |

| Applications | Used in environments requiring secure sealing and isolation. | Common in control panels, instrumentation, and user interfaces. |

| Sealing | Typically features environmental sealing (waterproof, dustproof). | Sealing varies; may include gaskets or O-rings for panel integrity. |

| Installation Complexity | Requires drilling through bulkhead and securing with nuts or clamps. | Easier installation; mounted on panel surface with screws. |

| Mechanical Strength | Higher mechanical stability due to through-bulkhead mounting. | Moderate mechanical stability depending on panel material. |

| Size Constraints | Needs clearance through bulkhead; size depends on panel thickness. | Limited by panel surface area and cutout size. |

| Common Connector Types | Circular, coaxial bulkhead connectors. | D-sub, terminal blocks, switches often panel mounted. |

Introduction to Bulkhead and Panel Mount Connectors

Bulkhead connectors are designed to pass through a bulkhead or enclosure wall, providing a secure and sealed interface for electrical or data connections, ideal for maintaining environmental protection. Panel mount connectors attach directly to a panel's surface, offering easy access and streamlined installation for external device connections. Choosing the right connector depends on your application's need for durability, space optimization, and accessibility.

Key Features of Bulkhead Connectors

Bulkhead connectors are designed for secure and robust connections through panel walls, featuring a threaded or flange mounting system that ensures a tight fit and environmental sealing. They offer enhanced durability and protection against dust, moisture, and mechanical stress, making them ideal for industrial and outdoor applications. Their key features include easy installation, reliable electrical performance, and resistance to vibration and corrosion, which distinguishes them from typical panel mount connectors.

Key Features of Panel Mount Connectors

Panel mount connectors feature a robust design that ensures secure attachment to a chassis or enclosure, providing reliable mechanical stability and easy access for connection and disconnection. They often include mounting flanges or threaded collars for firm installation, enhancing durability in harsh environments. These connectors support a wide variety of configurations, making them ideal for applications requiring fixed, accessible interface points on equipment panels.

Installation Methods: Bulkhead vs Panel Mount

Bulkhead connectors secure through a chassis or enclosure wall using threaded coupling nuts or flange mounting, offering robust mechanical stability and sealed connections ideal for harsh environments. Panel mount connectors attach directly to a device's front panel with screws or snap-in mechanisms, enabling easy access for frequent connectivity changes and streamlined front-panel integration. Your choice depends on installation environment and accessibility requirements, with bulkhead connectors favored for rugged, permanent setups and panel mounts suited for user-friendly, accessible interfaces.

Application Scenarios: Where Each Connector Excels

Bulkhead connectors excel in applications requiring secure, sealed connections through enclosures or bulkheads, making them ideal for rugged environments like aerospace, marine, and industrial machinery. Panel mount connectors are designed for easy installation on equipment front panels, offering accessible and durable interfaces perfect for consumer electronics, telecommunications, and control panels. Your choice depends on whether you need robust environmental sealing or convenient user access in your connectivity solution.

Environmental Sealing and Protection

Bulkhead connectors provide superior environmental sealing by integrating a robust housing that prevents dust, moisture, and contaminants from penetrating through panel openings, ensuring reliable protection in harsh conditions. Panel mount connectors typically rely on gaskets and sealing washers to maintain protection, but may offer less comprehensive sealing compared to bulkhead designs due to potential gaps around the mounting surfaces. The enhanced sealing and rugged construction of bulkhead connectors make them ideal for use in outdoor, industrial, or military applications where environmental exposure is a significant concern.

Mechanical Strength and Durability

Bulkhead connectors provide superior mechanical strength and durability due to their robust mounting method through a panel or enclosure, which distributes stress evenly and resists vibration and mechanical shocks. Panel mount connectors, while also designed for secure installation, typically offer less reinforcement compared to bulkhead types as they are usually attached only to the surface, making them more susceptible to wear under heavy mechanical stress. The choice between bulkhead and panel mount connectors largely depends on application requirements for structural support and long-term durability in harsh operating environments.

Ease of Maintenance and Replacement

Bulkhead connectors offer superior ease of maintenance and replacement by allowing quick disconnection without disturbing internal components, making them ideal for systems requiring frequent access. Panel mount connectors provide secure attachment but often necessitate removing the entire panel or dismantling surrounding hardware for replacement, increasing downtime. Their design differences significantly impact serviceability, with bulkhead connectors preferred in applications prioritizing rapid maintenance cycles.

Cost Considerations and Budget Impact

Bulkhead connectors typically offer cost savings in large-scale production due to easier installation and standardization, reducing labor and assembly expenses. Panel mount connectors may have higher upfront costs because of more complex mounting requirements but can provide durability and better sealing, potentially lowering long-term maintenance costs. Evaluating your project's volume and environmental needs will help determine which connector type optimizes your budget effectively.

Choosing the Right Connector for Your Project

Selecting the right connector for your project involves understanding the key differences between bulkhead connectors and panel mount connectors. Bulkhead connectors are designed to pass through a panel or enclosure, providing a secure and robust connection point with enhanced environmental protection, making them ideal for industrial or rugged applications. Panel mount connectors, which are mounted directly onto a device's front panel, offer easy access and streamlined aesthetics, perfect for user interfaces or control panels where convenience and appearance matter.

bulkhead connector vs panel mount connector Infographic

electrown.com

electrown.com