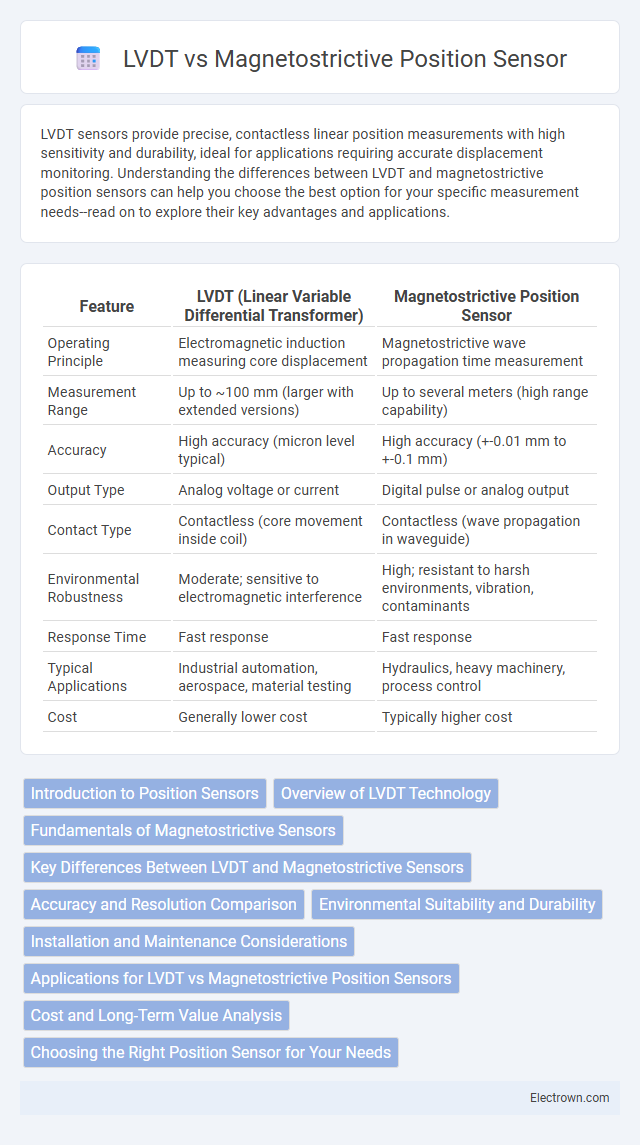

LVDT sensors provide precise, contactless linear position measurements with high sensitivity and durability, ideal for applications requiring accurate displacement monitoring. Understanding the differences between LVDT and magnetostrictive position sensors can help you choose the best option for your specific measurement needs--read on to explore their key advantages and applications.

Table of Comparison

| Feature | LVDT (Linear Variable Differential Transformer) | Magnetostrictive Position Sensor |

|---|---|---|

| Operating Principle | Electromagnetic induction measuring core displacement | Magnetostrictive wave propagation time measurement |

| Measurement Range | Up to ~100 mm (larger with extended versions) | Up to several meters (high range capability) |

| Accuracy | High accuracy (micron level typical) | High accuracy (+-0.01 mm to +-0.1 mm) |

| Output Type | Analog voltage or current | Digital pulse or analog output |

| Contact Type | Contactless (core movement inside coil) | Contactless (wave propagation in waveguide) |

| Environmental Robustness | Moderate; sensitive to electromagnetic interference | High; resistant to harsh environments, vibration, contaminants |

| Response Time | Fast response | Fast response |

| Typical Applications | Industrial automation, aerospace, material testing | Hydraulics, heavy machinery, process control |

| Cost | Generally lower cost | Typically higher cost |

Introduction to Position Sensors

Position sensors measure the displacement or position of an object with high precision, essential for automation and control systems. LVDT (Linear Variable Differential Transformer) sensors use electromagnetic induction to detect linear position changes, offering excellent accuracy and durability in harsh environments. Magnetostrictive position sensors rely on the time delay of torsional waves in a magnetostrictive wire, providing non-contact measurement with high resolution and fast response, ideal for dynamic industrial applications.

Overview of LVDT Technology

LVDT technology utilizes a movable ferromagnetic core inside a cylindrical coil assembly to produce an AC output voltage proportional to linear displacement, offering high accuracy and repeatability in position sensing. These sensors are widely used in industrial automation due to their frictionless design and excellent durability in harsh environments. Your choice of LVDT ensures reliable measurements with minimal wear, making them ideal for applications demanding precise position feedback.

Fundamentals of Magnetostrictive Sensors

Magnetostrictive position sensors utilize the principle of magnetostriction, where ferromagnetic materials change shape or dimension in response to magnetic fields, generating ultrasonic pulses along a waveguide. These sensors measure the time delay of the mechanical pulse reflected by a movable magnet, enabling highly precise, non-contact position detection. Compared to LVDTs, magnetostrictive sensors offer superior durability, longer measuring ranges, and immunity to environmental contaminants, making them suited for industrial automation and heavy machinery.

Key Differences Between LVDT and Magnetostrictive Sensors

LVDT sensors measure linear displacement using a movable core inside a transformer coil, providing high accuracy and frictionless operation ideal for precise position feedback. Magnetostrictive sensors determine position based on the time delay of a torsional strain wave generated by a magnetic pulse interacting with a ferromagnetic waveguide, offering robust performance in harsh industrial environments. The key differences include LVDTs' reliance on electromagnetic induction for displacement measurement versus magnetostrictive sensors' use of time-of-flight measurement for position, with LVDTs excelling in precision and magnetostrictive sensors favored for long stroke lengths and durability.

Accuracy and Resolution Comparison

LVDT (Linear Variable Differential Transformer) sensors typically offer high accuracy with resolutions down to microns, making them ideal for precise displacement measurements. Magnetostrictive position sensors provide robust accuracy in harsh environments, with resolutions often ranging from sub-millimeter to a few microns, depending on the design and signal processing. The choice between LVDT and magnetostrictive sensors depends on the required accuracy, resolution, and environmental conditions, with LVDTs generally excelling in ultra-precise laboratory settings.

Environmental Suitability and Durability

LVDT sensors offer excellent environmental suitability with robust performance in harsh conditions such as extreme temperatures, dust, and moisture due to their sealed, non-contact design. Magnetostrictive position sensors provide superior durability and resistance to shock, vibration, and electromagnetic interference, making them ideal for heavy machinery and industrial automation. Your choice depends on the specific environmental challenges and longevity required for accurate position sensing in your application.

Installation and Maintenance Considerations

LVDT sensors require precise alignment to avoid measurement errors, with simple mechanical mounting and no contact wear, resulting in low maintenance needs. Magnetostrictive position sensors offer non-contact measurement with flexible installation options, but demand care in cable routing and protection to ensure long-term reliability. Both sensor types benefit from stable environmental conditions to maintain accuracy and minimize calibration frequency.

Applications for LVDT vs Magnetostrictive Position Sensors

LVDT sensors are widely used in aerospace, automotive testing, and industrial automation for precise displacement measurement under harsh environments. Magnetostrictive position sensors find extensive application in hydraulic cylinder position feedback, mobile machinery, and fluid power systems due to their non-contact measurement and high durability. Both sensor types excel in linear position sensing but differ in integration complexity and suitability for dynamic or static environments.

Cost and Long-Term Value Analysis

LVDT sensors typically have lower upfront costs and simpler construction, making them a cost-effective choice for many applications. Magnetostrictive position sensors, though more expensive initially, offer superior durability and longer operational life with minimal maintenance, resulting in better long-term value. The higher precision and robustness of magnetostrictive sensors often justify their increased investment for critical and continuous monitoring systems.

Choosing the Right Position Sensor for Your Needs

Choosing the right position sensor depends on factors like measurement range, accuracy, and environmental conditions. LVDT sensors offer high precision, durability, and are ideal for applications requiring frictionless measurement, while magnetostrictive sensors provide non-contact sensing with long stroke lengths and robust performance in harsh environments. Understanding your specific application requirements ensures you select the sensor that delivers optimal reliability and measurement accuracy.

LVDT vs Magnetostrictive position sensor Infographic

electrown.com

electrown.com