IEPE sensors provide built-in signal conditioning with constant current excitation, offering high sensitivity and low noise for dynamic measurements. Understanding the differences between IEPE and charge output sensors will help you choose the right sensor for your application; continue reading to explore their advantages and ideal use cases.

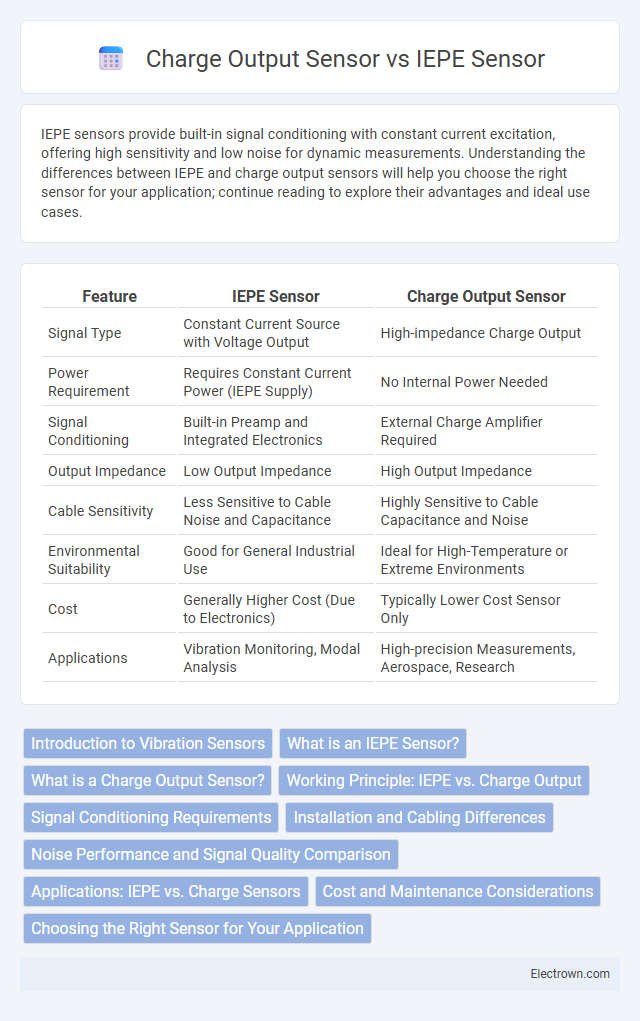

Table of Comparison

| Feature | IEPE Sensor | Charge Output Sensor |

|---|---|---|

| Signal Type | Constant Current Source with Voltage Output | High-impedance Charge Output |

| Power Requirement | Requires Constant Current Power (IEPE Supply) | No Internal Power Needed |

| Signal Conditioning | Built-in Preamp and Integrated Electronics | External Charge Amplifier Required |

| Output Impedance | Low Output Impedance | High Output Impedance |

| Cable Sensitivity | Less Sensitive to Cable Noise and Capacitance | Highly Sensitive to Cable Capacitance and Noise |

| Environmental Suitability | Good for General Industrial Use | Ideal for High-Temperature or Extreme Environments |

| Cost | Generally Higher Cost (Due to Electronics) | Typically Lower Cost Sensor Only |

| Applications | Vibration Monitoring, Modal Analysis | High-precision Measurements, Aerospace, Research |

Introduction to Vibration Sensors

Vibration sensors are critical for monitoring mechanical systems, with IEPE sensors and charge output sensors being two primary types used for precise measurements. IEPE sensors contain built-in electronics that simplify signal processing and offer low impedance output, making them suitable for long cable runs and resistance to electromagnetic interference. Charge output sensors produce raw electrical charge directly from the piezoelectric element, requiring external charge amplifiers but offering excellent high-frequency response and stability in extreme environments, ensuring your vibration data remains accurate and reliable.

What is an IEPE Sensor?

An IEPE sensor (Integrated Electronics Piezo-Electric) incorporates built-in electronics that provide constant current excitation and convert the high impedance piezoelectric signal into a low impedance output, simplifying signal conditioning and improving noise immunity. It is commonly used in vibration, shock, and pressure measurements due to its ease of integration with standard data acquisition systems. Compared to charge output sensors, IEPE sensors eliminate the need for external charge amplifiers, offering a more convenient and reliable solution for dynamic measurement applications.

What is a Charge Output Sensor?

A Charge Output Sensor generates an electrical charge proportional to the mechanical stress or vibration it detects, making it ideal for high-impedance, low-noise environments. Unlike IEPE sensors that require constant current power and output a voltage signal, charge sensors need a specialized charge amplifier to convert the generated charge into a usable voltage output. Your choice between IEPE and charge output sensors depends on application conditions such as temperature range, cable length, and signal sensitivity.

Working Principle: IEPE vs. Charge Output

IEPE sensors operate by supplying a constant current to an internal preamplifier, converting the sensor's capacitance changes into a low-impedance voltage signal, facilitating immediate signal conditioning and noise reduction. Charge output sensors generate an electrical charge proportional to the mechanical stress, requiring a high-impedance charge amplifier for signal conversion and buffering due to their high-impedance output. The fundamental difference lies in IEPE sensors delivering conditioned, low-impedance voltage signals directly, while charge output sensors produce raw charge signals necessitating external amplification and signal processing.

Signal Conditioning Requirements

IEPE sensors require constant current excitation and integrate built-in signal conditioning, simplifying installation and reducing susceptibility to electrical noise. Charge output sensors generate high-impedance signals that need external charge amplifiers or conditioners to convert charge to voltage, making them sensitive to cable noise and requiring careful shielding. Your choice impacts ease of setup and signal integrity, especially in environments with high electromagnetic interference.

Installation and Cabling Differences

IEPE sensors utilize built-in electronics that require constant current excitation, allowing for simpler two-wire cabling with integrated power and signal transmission, which reduces installation complexity and susceptibility to electrical noise. Charge output sensors lack internal electronics and require separate, low-noise charge amplifiers with shielded cables to prevent signal loss and interference, leading to more complex installation and cabling requirements. The distinct cabling approaches directly influence sensor placement flexibility, signal integrity, and overall system design in vibration and acoustic measurement applications.

Noise Performance and Signal Quality Comparison

IEPE sensors exhibit lower noise floors and improved signal quality compared to charge output sensors due to their built-in electronics that condition the signal at the source. Charge output sensors require external charge amplifiers, which can introduce additional noise and are more susceptible to signal degradation over long cable runs. As a result, IEPE sensors are preferred in applications demanding high fidelity vibration measurements and minimal noise interference.

Applications: IEPE vs. Charge Sensors

IEPE sensors are widely used in industrial machinery monitoring, automotive testing, and aerospace applications thanks to their built-in signal conditioning and ease of integration with data acquisition systems. Charge output sensors excel in high-temperature environments, structural health monitoring, and research laboratories where long cable runs and low noise performance are critical. The choice between IEPE and charge sensors depends on factors such as environmental conditions, signal processing capabilities, and system compatibility requirements.

Cost and Maintenance Considerations

IEPE sensors generally offer lower initial costs and simplified maintenance due to built-in signal conditioning, reducing the need for external equipment and regular calibration. Charge output sensors often require more expensive charge amplifiers and frequent recalibration, leading to higher long-term maintenance expenses. The integrated electronics in IEPE sensors also enhance durability and reduce downtime compared to the more delicate charge sensors.

Choosing the Right Sensor for Your Application

Selecting the appropriate sensor depends on application requirements such as frequency range, sensitivity, and environmental conditions. IEPE sensors offer built-in electronics for low-noise signals and ease of integration, making them ideal for high-frequency vibration measurements in industrial settings. Charge output sensors excel in high-voltage, extreme temperature environments and are preferred when cable lengths are long or when absolute signal stability is critical.

IEPE sensor vs Charge output sensor Infographic

electrown.com

electrown.com