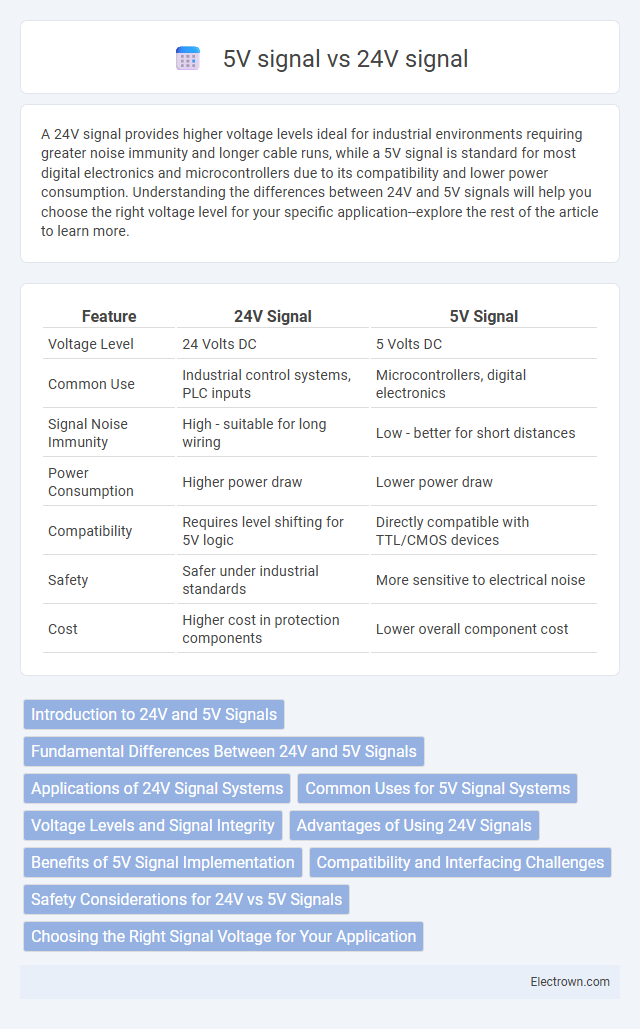

A 24V signal provides higher voltage levels ideal for industrial environments requiring greater noise immunity and longer cable runs, while a 5V signal is standard for most digital electronics and microcontrollers due to its compatibility and lower power consumption. Understanding the differences between 24V and 5V signals will help you choose the right voltage level for your specific application--explore the rest of the article to learn more.

Table of Comparison

| Feature | 24V Signal | 5V Signal |

|---|---|---|

| Voltage Level | 24 Volts DC | 5 Volts DC |

| Common Use | Industrial control systems, PLC inputs | Microcontrollers, digital electronics |

| Signal Noise Immunity | High - suitable for long wiring | Low - better for short distances |

| Power Consumption | Higher power draw | Lower power draw |

| Compatibility | Requires level shifting for 5V logic | Directly compatible with TTL/CMOS devices |

| Safety | Safer under industrial standards | More sensitive to electrical noise |

| Cost | Higher cost in protection components | Lower overall component cost |

Introduction to 24V and 5V Signals

24V signals typically power industrial automation systems, providing higher voltage levels suitable for long-distance transmission and noise resistance, while 5V signals are common in low-power electronics and microcontroller circuits due to their compatibility with digital logic levels. The choice between 24V and 5V signals impacts your device's design, influencing power consumption, signal integrity, and safety considerations. Understanding the operational context of each voltage level ensures optimal performance and reliable communication in your electronic or control system.

Fundamental Differences Between 24V and 5V Signals

A 24V signal operates at a higher voltage level compared to a 5V signal, providing greater noise immunity and longer transmission distances in industrial environments. The increased voltage allows 24V signals to drive more robust actuators and sensors, essential for reliable control in automation systems, whereas 5V signals are typically used in low-power digital electronics and microcontrollers. Understanding your system's voltage requirements ensures compatibility and prevents damage to components by matching signal levels to device specifications.

Applications of 24V Signal Systems

24V signal systems are widely used in industrial automation, PLCs, and machine control due to their higher noise immunity and ability to drive longer cable lengths compared to 5V signals. They are preferred in environments with electrical interference, as the increased voltage improves signal integrity and reduces errors. Applications include sensors, actuators, and communication interfaces within factory floors and process control systems.

Common Uses for 5V Signal Systems

5V signal systems are commonly used in low-power digital electronics, such as microcontrollers, sensors, and communication devices, due to their compatibility with TTL logic levels and widespread industry standards. These systems often power and control devices within consumer electronics, embedded systems, and computer peripherals where low voltage operation ensures energy efficiency and safety. Your electronic projects benefit from 5V signaling for reliable interfacing with a vast array of integrated circuits and development boards like Arduino.

Voltage Levels and Signal Integrity

A 24V signal offers higher voltage levels compared to a 5V signal, resulting in improved noise immunity and better signal integrity over longer distances. Your electronic system benefits from the increased voltage margin of 24V signals, which reduces susceptibility to interference and voltage drops in industrial environments. However, careful design considerations are necessary when interfacing 24V signals with 5V logic to maintain reliable communication and prevent damage.

Advantages of Using 24V Signals

Using 24V signals in industrial automation offers increased noise immunity and greater transmission distances compared to 5V signals, reducing signal degradation in harsh environments. The higher voltage level enables more reliable switching of relays and actuators, enhancing system robustness and operational stability. Moreover, 24V signals align with common industrial standards, simplifying integration with existing equipment and reducing wiring complexity.

Benefits of 5V Signal Implementation

5V signal implementation offers significant benefits such as lower power consumption and improved compatibility with modern digital devices and microcontrollers. The reduced voltage level decreases the risk of component damage and enhances signal integrity in sensitive circuits. Your electronic designs achieve greater efficiency and reliability when leveraging 5V signals over higher voltage alternatives like 24V.

Compatibility and Interfacing Challenges

24V signals often exceed the input voltage tolerance of standard 5V logic circuits, requiring level shifters or voltage dividers to ensure compatibility and prevent damage. Directly interfacing 24V signals with 5V microcontrollers without proper voltage regulation can lead to unreliable data transmission and hardware failure. Designing robust interfacing circuits mandates attention to voltage thresholds, input protection, and signal integrity to achieve seamless communication between the two voltage domains.

Safety Considerations for 24V vs 5V Signals

A 24V signal offers increased safety margins compared to a 5V signal by providing better noise immunity and reduced susceptibility to voltage drops over long cable runs. Higher voltage signals like 24V minimize the risk of false triggering in industrial control systems, ensuring reliable operation in electrically noisy environments. However, 24V circuits require proper insulation and protective measures to prevent electrical hazards, whereas 5V signals are generally safer for direct human interaction but more prone to interference.

Choosing the Right Signal Voltage for Your Application

Choosing the right signal voltage depends on the application's requirements for noise immunity, power consumption, and compatibility with control systems. A 24V signal offers stronger noise resistance and longer transmission distances, making it ideal for industrial environments, while a 5V signal suits low-power, short-distance applications like microcontroller interfacing. Evaluating device specifications and environmental factors ensures efficient, reliable communication in the chosen voltage level.

24V signal vs 5V signal Infographic

electrown.com

electrown.com