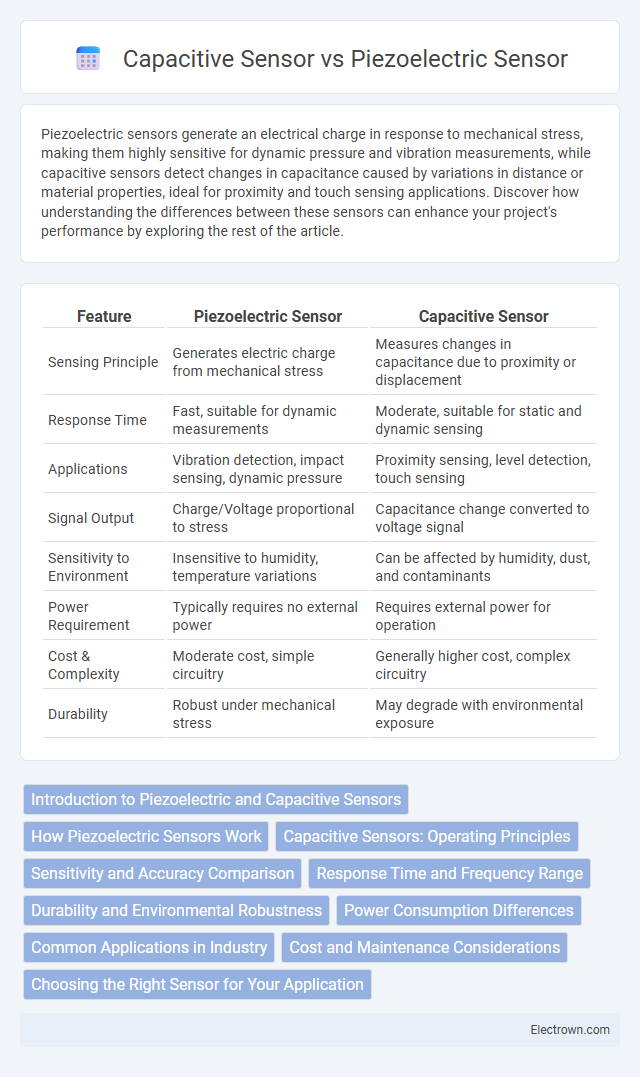

Piezoelectric sensors generate an electrical charge in response to mechanical stress, making them highly sensitive for dynamic pressure and vibration measurements, while capacitive sensors detect changes in capacitance caused by variations in distance or material properties, ideal for proximity and touch sensing applications. Discover how understanding the differences between these sensors can enhance your project's performance by exploring the rest of the article.

Table of Comparison

| Feature | Piezoelectric Sensor | Capacitive Sensor |

|---|---|---|

| Sensing Principle | Generates electric charge from mechanical stress | Measures changes in capacitance due to proximity or displacement |

| Response Time | Fast, suitable for dynamic measurements | Moderate, suitable for static and dynamic sensing |

| Applications | Vibration detection, impact sensing, dynamic pressure | Proximity sensing, level detection, touch sensing |

| Signal Output | Charge/Voltage proportional to stress | Capacitance change converted to voltage signal |

| Sensitivity to Environment | Insensitive to humidity, temperature variations | Can be affected by humidity, dust, and contaminants |

| Power Requirement | Typically requires no external power | Requires external power for operation |

| Cost & Complexity | Moderate cost, simple circuitry | Generally higher cost, complex circuitry |

| Durability | Robust under mechanical stress | May degrade with environmental exposure |

Introduction to Piezoelectric and Capacitive Sensors

Piezoelectric sensors generate an electric charge in response to mechanical stress, making them ideal for dynamic pressure, vibration, and force measurements. Capacitive sensors detect changes in capacitance caused by the displacement of a diaphragm or nearby object, commonly used for proximity, position, and humidity sensing. Your choice between piezoelectric and capacitive sensors depends on whether you need high-frequency response or precise low-frequency measurements with sensitivity to environmental changes.

How Piezoelectric Sensors Work

Piezoelectric sensors operate by converting mechanical stress or pressure into an electrical charge through the piezoelectric effect observed in certain crystalline materials. When these crystals deform under force, they generate a proportional voltage signal that can be measured and used for precise force, pressure, or vibration sensing. This direct conversion mechanism enables piezoelectric sensors to have high sensitivity, fast response times, and the ability to capture dynamic changes in physical parameters.

Capacitive Sensors: Operating Principles

Capacitive sensors operate by detecting changes in capacitance caused by variations in the dielectric material or distance between two conductive plates. They measure the electrical charge stored, which varies in response to proximity, pressure, or humidity changes. This principle enables high sensitivity and accuracy in applications such as touchscreens, proximity detection, and fluid level monitoring.

Sensitivity and Accuracy Comparison

Piezoelectric sensors exhibit high sensitivity to dynamic pressure changes, making them ideal for detecting vibrations and rapid force variations with excellent accuracy in transient measurements. Capacitive sensors offer superior accuracy in measuring static or slow-changing pressures due to their stable capacitance changes, providing precise readings in low-frequency applications. Sensitivity in piezoelectric sensors tends to decrease under static conditions, while capacitive sensors maintain consistent performance, highlighting a clear division in application suitability based on measurement type.

Response Time and Frequency Range

Piezoelectric sensors exhibit extremely fast response times typically in the microsecond range, making them ideal for high-frequency applications up to several megahertz. Capacitive sensors generally have slower response times, often in the millisecond range, with effective frequency ranges limited to kilohertz levels. The superior frequency response of piezoelectric sensors suits dynamic measurements, while capacitive sensors are preferred for static or low-frequency applications.

Durability and Environmental Robustness

Piezoelectric sensors offer high durability with their ability to withstand extreme temperatures and mechanical shocks, making them suitable for harsh industrial environments. Capacitive sensors, while generally robust, can be more sensitive to moisture, dust, and environmental contaminants, which may affect their performance and lifespan. The inherent material properties of piezoelectric crystals contribute to superior longevity in rugged conditions compared to the typically polymer-based dielectric layers in capacitive sensors.

Power Consumption Differences

Piezoelectric sensors typically consume less power than capacitive sensors because they generate an electrical charge directly from mechanical stress without requiring a continuous power supply. Capacitive sensors rely on an external power source to create an electric field and measure changes in capacitance, leading to higher power consumption during operation. If power efficiency is a critical factor for your sensor application, piezoelectric sensors often provide a more energy-efficient solution.

Common Applications in Industry

Piezoelectric sensors are widely used in industrial applications for vibration monitoring, machine condition analysis, and pressure measurement due to their high sensitivity and dynamic response. Capacitive sensors excel in non-contact position sensing, level detection, and proximity sensing within automated manufacturing and quality control systems. Your choice between these sensors depends on factors like measurement type, environmental conditions, and required sensitivity.

Cost and Maintenance Considerations

Piezoelectric sensors generally cost more upfront but offer lower maintenance due to their solid-state design and durability in harsh environments. Capacitive sensors tend to be less expensive initially but may require more frequent calibration and cleaning to maintain accuracy, increasing long-term maintenance costs. Your choice should weigh initial budget constraints against ongoing service needs to optimize overall expenditure.

Choosing the Right Sensor for Your Application

Choosing the right sensor for your application depends on the specific performance requirements and environmental conditions. Piezoelectric sensors excel in dynamic pressure and vibration measurement due to their high-frequency response and durability, making them ideal for industrial machinery and impact detection. Capacitive sensors offer superior sensitivity for detecting static or low-frequency changes, such as humidity or proximity, making them suitable for touch panels and precise position sensing in controlled environments.

Piezoelectric sensor vs Capacitive sensor Infographic

electrown.com

electrown.com