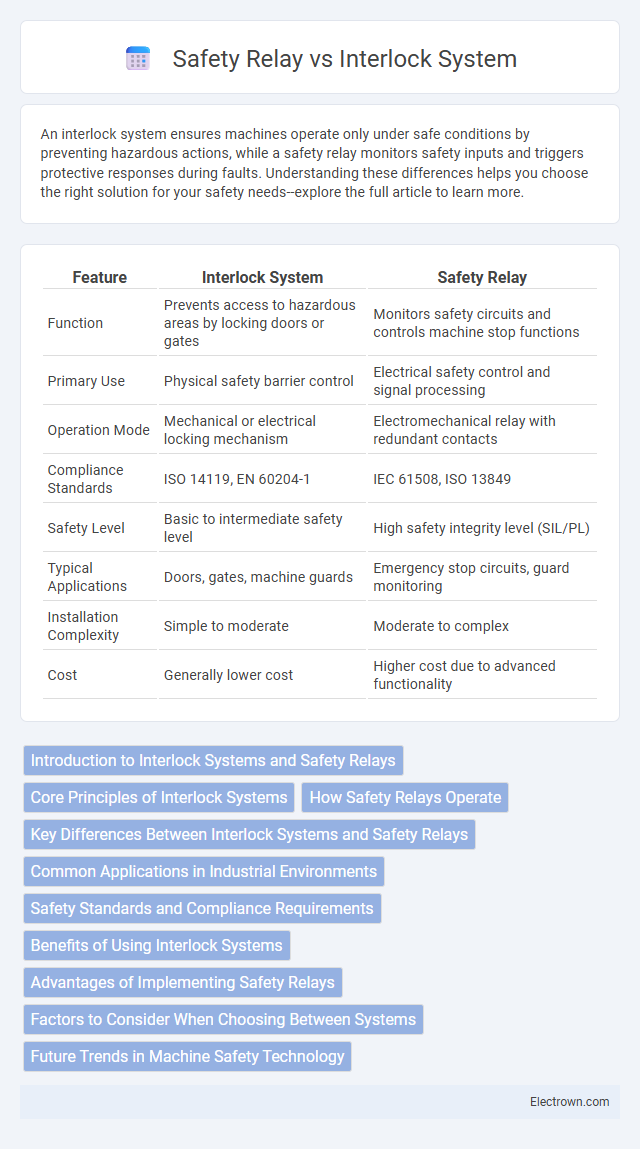

An interlock system ensures machines operate only under safe conditions by preventing hazardous actions, while a safety relay monitors safety inputs and triggers protective responses during faults. Understanding these differences helps you choose the right solution for your safety needs--explore the full article to learn more.

Table of Comparison

| Feature | Interlock System | Safety Relay |

|---|---|---|

| Function | Prevents access to hazardous areas by locking doors or gates | Monitors safety circuits and controls machine stop functions |

| Primary Use | Physical safety barrier control | Electrical safety control and signal processing |

| Operation Mode | Mechanical or electrical locking mechanism | Electromechanical relay with redundant contacts |

| Compliance Standards | ISO 14119, EN 60204-1 | IEC 61508, ISO 13849 |

| Safety Level | Basic to intermediate safety level | High safety integrity level (SIL/PL) |

| Typical Applications | Doors, gates, machine guards | Emergency stop circuits, guard monitoring |

| Installation Complexity | Simple to moderate | Moderate to complex |

| Cost | Generally lower cost | Higher cost due to advanced functionality |

Introduction to Interlock Systems and Safety Relays

Interlock systems and safety relays are critical components in industrial automation to ensure machine safety and prevent accidents. Interlock systems restrict access or operation until dangerous conditions are resolved, while safety relays monitor inputs from sensors and emergency stops to initiate safe shutdowns. Your choice between these depends on the complexity of safety requirements and the need for reliable fault detection and response.

Core Principles of Interlock Systems

Interlock systems operate on the core principle of preventing hazardous machine operations by ensuring that specific conditions are met before allowing equipment to function, typically using mechanical or electrical means to enforce safety protocols. These systems rely on real-time monitoring of safety gates, access panels, or sensor feedback to interrupt power or control signals if unsafe conditions arise. Safety relays complement interlock systems by providing fail-safe circuitry that monitors input signals and triggers immediate shutdowns or alerts when a fault or unauthorized access is detected, ensuring redundant protection.

How Safety Relays Operate

Safety relays operate by continuously monitoring input signals from safety devices such as emergency stops, safety gates, and light curtains to detect faults or hazardous conditions. They use redundant internal circuits and self-checking mechanisms to ensure the reliability and integrity of safety functions, immediately triggering a controlled shutdown if an unsafe state is detected. Unlike basic interlock systems, safety relays provide failsafe responses that comply with international safety standards like ISO 13849-1 and IEC 62061.

Key Differences Between Interlock Systems and Safety Relays

Interlock systems primarily function as mechanical or electrical devices designed to prevent access to hazardous areas, ensuring operator safety by physically restricting machine operations. Safety relays are specialized control components that monitor and manage safety functions by processing signals from multiple sensors to initiate machine shutdowns in dangerous conditions. The key difference lies in interlock systems focusing on access prevention through physical or switch-based means, while safety relays emphasize reliable electronic monitoring and control to enhance system-wide safety compliance.

Common Applications in Industrial Environments

Interlock systems are primarily used in industrial environments to prevent access to hazardous areas by ensuring machines remain off until safety conditions are met, commonly found in access doors and guard enclosures. Safety relays are frequently deployed to monitor emergency stop circuits and safety sensors, providing reliable shutdown of machinery in applications like conveyor systems and robotic cells. Both systems enhance workplace safety by controlling machine operation, but safety relays offer more comprehensive fault detection and diagnostic capabilities essential for complex automation processes.

Safety Standards and Compliance Requirements

Interlock systems and safety relays must comply with stringent safety standards such as IEC 61508 and ISO 13849 to ensure reliable machine safeguarding. Interlock systems often integrate directly with mechanical guards and access points, meeting compliance through physical access control, while safety relays provide certified electronic monitoring and fault detection for control circuits. Understanding the specific standard requirements and risk assessments ensures the correct selection and implementation for workplace safety and regulatory compliance.

Benefits of Using Interlock Systems

Interlock systems enhance operational safety by automatically preventing equipment from functioning under hazardous conditions, reducing the risk of accidents and equipment damage. They provide precise control and monitoring capabilities, ensuring compliance with safety standards and minimizing downtime. Integrating interlock systems streamlines maintenance processes and increases overall system reliability compared to traditional safety relays.

Advantages of Implementing Safety Relays

Safety relays provide enhanced reliability and fail-safe operation by continuously monitoring control signals and ensuring immediate system shutdown during faults, reducing the risk of equipment damage and operator injury. They are designed with redundant internal components and self-monitoring features that detect wiring faults, improving overall safety compliance and reducing downtime. Compared to basic interlock systems, safety relays support complex applications with flexible configurations and integration into safety control networks, facilitating easier diagnostics and maintenance.

Factors to Consider When Choosing Between Systems

When choosing between an interlock system and a safety relay, key factors include the complexity of the application, required response time, and the level of safety integrity needed. Interlock systems offer straightforward mechanical or electronic solutions suitable for simple safety tasks, while safety relays provide advanced diagnostics and redundancy for higher-risk environments. Your decision should also consider compliance with safety standards like ISO 13849 or IEC 62061 to ensure optimal protection.

Future Trends in Machine Safety Technology

Future trends in machine safety technology emphasize advanced interlock systems featuring IoT connectivity and predictive diagnostics, enhancing real-time hazard detection and maintenance alerts. Safety relays are evolving with integrated smart functions and fail-safe communication protocols, ensuring higher reliability and compliance with stringent industry standards. Your machinery benefits from these innovations through improved operational safety and minimized downtime, driving efficient and secure manufacturing processes.

interlock system vs safety relay Infographic

electrown.com

electrown.com