Steel diaphragms offer greater durability and flexibility in high-pressure applications, while ceramic diaphragms excel in chemical resistance and precision measurement due to their rigidity and corrosion resistance. Discover which diaphragm type best suits your specific industrial needs by exploring the detailed comparison in the following article.

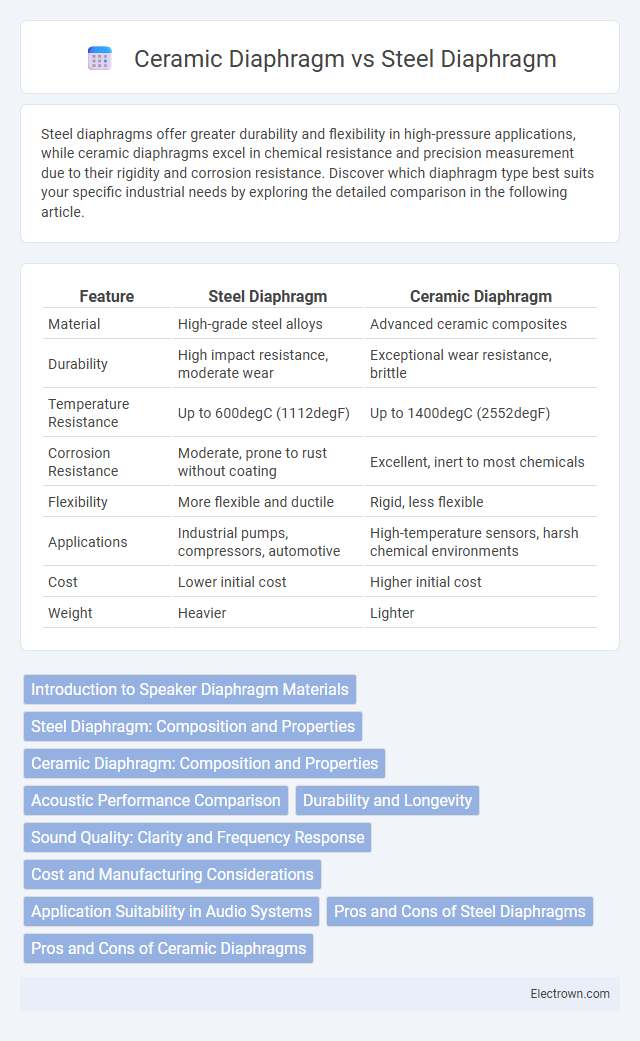

Table of Comparison

| Feature | Steel Diaphragm | Ceramic Diaphragm |

|---|---|---|

| Material | High-grade steel alloys | Advanced ceramic composites |

| Durability | High impact resistance, moderate wear | Exceptional wear resistance, brittle |

| Temperature Resistance | Up to 600degC (1112degF) | Up to 1400degC (2552degF) |

| Corrosion Resistance | Moderate, prone to rust without coating | Excellent, inert to most chemicals |

| Flexibility | More flexible and ductile | Rigid, less flexible |

| Applications | Industrial pumps, compressors, automotive | High-temperature sensors, harsh chemical environments |

| Cost | Lower initial cost | Higher initial cost |

| Weight | Heavier | Lighter |

Introduction to Speaker Diaphragm Materials

Steel diaphragms in speakers offer high durability and excellent magnetic conductivity, which enhances sound sensitivity and overall efficiency. Ceramic diaphragms, known for their rigidity and lightweight properties, provide superior acoustic precision with minimal distortion, ideal for high-frequency sound reproduction. Choosing the right diaphragm material impacts Your speaker's performance, balancing factors like sound clarity, durability, and responsiveness.

Steel Diaphragm: Composition and Properties

Steel diaphragms are composed primarily of high-grade stainless steel, offering exceptional strength, durability, and resistance to corrosion and high temperatures. Their metallic properties enable superior flexibility and structural integrity under pressure, making them suitable for demanding industrial applications. Your choice of a steel diaphragm ensures reliable performance and longevity in environments where chemical and mechanical stresses are prevalent.

Ceramic Diaphragm: Composition and Properties

Ceramic diaphragms are primarily composed of advanced ceramics such as alumina, zirconia, or piezoelectric materials, offering exceptional hardness, chemical inertness, and high thermal stability. These properties enable superior wear resistance, corrosion resistance, and the ability to operate under extreme temperature and pressure conditions. The inherent brittleness of ceramic materials is offset by their enhanced sensitivity and durability in applications like sensors, actuators, and precision measurement devices.

Acoustic Performance Comparison

Steel diaphragms offer high durability and excellent transient response, producing a bright and detailed sound signature ideal for clear midrange and treble frequencies. Ceramic diaphragms provide superior stiffness and low distortion, resulting in precise sound reproduction with enhanced clarity and controlled resonance in high-frequency ranges. The choice between steel and ceramic diaphragms depends on the desired balance between durability, transient accuracy, and tonal characteristics in audio applications.

Durability and Longevity

Steel diaphragms offer superior durability due to their high tensile strength and resistance to wear, making them ideal for applications requiring long service life under heavy stress. Ceramic diaphragms provide excellent longevity in corrosive environments because of their chemical inertness and hardness, ensuring minimal degradation over time. Choosing between steel and ceramic diaphragms depends on whether your priority is mechanical toughness or chemical resistance for prolonged use.

Sound Quality: Clarity and Frequency Response

Steel diaphragms deliver crisp sound clarity and a wider frequency response, enhancing treble precision and midrange detail for a dynamic listening experience. Ceramic diaphragms tend to produce a warmer, more mellow tone but may sacrifice some high-frequency extension and sharpness. The choice between steel and ceramic diaphragms significantly impacts audio fidelity, particularly in genres requiring detailed high-end articulation.

Cost and Manufacturing Considerations

Steel diaphragms generally have lower manufacturing costs due to the abundance of raw materials and streamlined fabrication processes such as stamping and welding. Ceramic diaphragms demand higher expenses driven by specialized materials, precision machining, and sintering processes required to achieve durability and performance in high-temperature or corrosive environments. Cost considerations often favor steel diaphragms for large-scale production, while ceramic diaphragms justify the premium in applications needing superior chemical resistance and thermal stability.

Application Suitability in Audio Systems

Steel diaphragms excel in audio systems requiring high durability and resistance to moisture, making them ideal for portable speakers and outdoor applications. Ceramic diaphragms offer superior rigidity and thermal stability, enhancing audio clarity and precision in high-fidelity headphones and professional studio monitors. Choosing between steel and ceramic diaphragms depends on balancing durability needs with the desired sound accuracy and environmental conditions.

Pros and Cons of Steel Diaphragms

Steel diaphragms offer high strength, durability, and excellent resistance to wear and corrosion, making them ideal for heavy-duty industrial applications. However, they tend to be heavier and less flexible than ceramic diaphragms, which can limit their performance in precision or high-frequency settings. Your choice should balance the need for toughness and longevity against requirements for sensitivity and weight in specific applications.

Pros and Cons of Ceramic Diaphragms

Ceramic diaphragms offer excellent chemical resistance and durability, making them ideal for harsh environments where corrosion is a concern. However, their brittleness can lead to cracking under mechanical stress, reducing long-term reliability compared to steel diaphragms. You benefit from precise performance and low hysteresis, but must consider the higher risk of physical damage when selecting ceramic diaphragm components.

Steel diaphragm vs Ceramic diaphragm Infographic

electrown.com

electrown.com