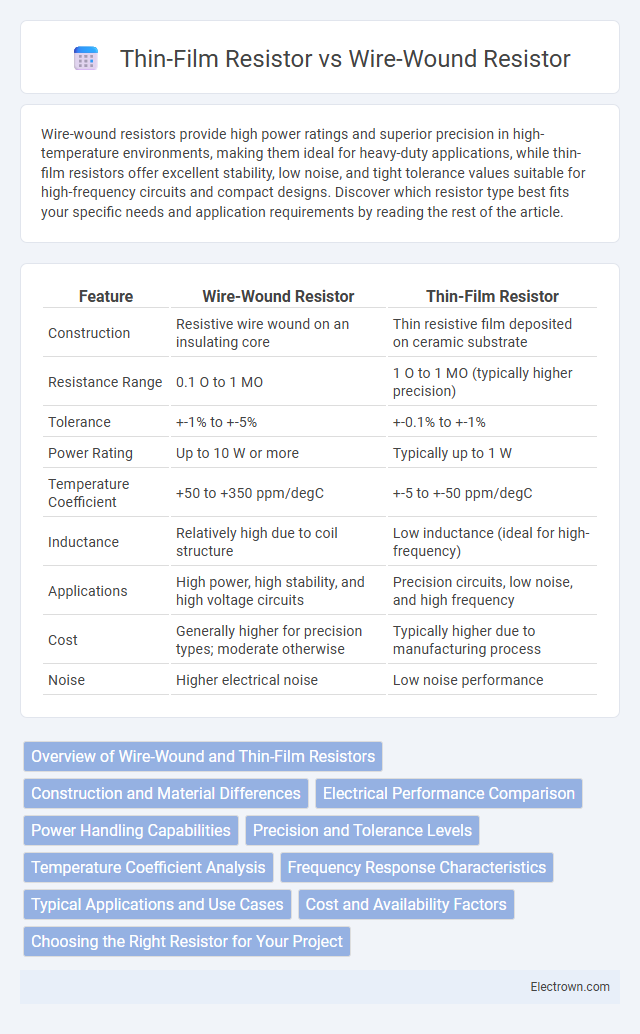

Wire-wound resistors provide high power ratings and superior precision in high-temperature environments, making them ideal for heavy-duty applications, while thin-film resistors offer excellent stability, low noise, and tight tolerance values suitable for high-frequency circuits and compact designs. Discover which resistor type best fits your specific needs and application requirements by reading the rest of the article.

Table of Comparison

| Feature | Wire-Wound Resistor | Thin-Film Resistor |

|---|---|---|

| Construction | Resistive wire wound on an insulating core | Thin resistive film deposited on ceramic substrate |

| Resistance Range | 0.1 O to 1 MO | 1 O to 1 MO (typically higher precision) |

| Tolerance | +-1% to +-5% | +-0.1% to +-1% |

| Power Rating | Up to 10 W or more | Typically up to 1 W |

| Temperature Coefficient | +50 to +350 ppm/degC | +-5 to +-50 ppm/degC |

| Inductance | Relatively high due to coil structure | Low inductance (ideal for high-frequency) |

| Applications | High power, high stability, and high voltage circuits | Precision circuits, low noise, and high frequency |

| Cost | Generally higher for precision types; moderate otherwise | Typically higher due to manufacturing process |

| Noise | Higher electrical noise | Low noise performance |

Overview of Wire-Wound and Thin-Film Resistors

Wire-wound resistors consist of a metal wire coil wrapped around an insulating core, offering high power dissipation and excellent precision in high-current applications. Thin-film resistors feature a thin layer of resistive material deposited onto a ceramic substrate, providing superior stability, low noise, and tight tolerance control for precision electronic circuits. Both resistor types are essential in circuit design, with wire-wound resistors excelling in power handling and thin-film resistors preferred for accuracy and miniaturization.

Construction and Material Differences

Wire-wound resistors consist of a metal wire, usually nichrome or tungsten, tightly wound around a ceramic, plastic, or fiberglass core, offering high power ratings and excellent durability under high temperatures. Thin-film resistors feature a thin layer of resistive material, typically metal oxides or alloys, deposited onto an insulating substrate by sputtering or vapor deposition, providing precise resistance values with low noise and excellent stability. The fundamental construction differences lead wire-wound resistors to excel in power dissipation and inductive environments, while thin-film resistors deliver superior accuracy and frequency response.

Electrical Performance Comparison

Wire-wound resistors exhibit superior power handling and thermal stability, making them ideal for high-precision applications with high current loads, while thin-film resistors provide lower noise, better tolerance, and higher frequency performance suited for sensitive electronic circuits. Wire-wound types have higher inductance and slower response times compared to thin-film resistors, which offer minimal inductance and faster transient response. The choice between wire-wound and thin-film resistors depends on the specific electrical requirements, including power dissipation, frequency range, and precision needed for the application.

Power Handling Capabilities

Wire-wound resistors offer superior power handling capabilities, typically ranging from 5 watts up to several hundred watts, making them ideal for high-power applications and heavy load conditions. Thin-film resistors generally have lower power ratings, commonly up to 1 watt, due to their smaller size and delicate thin-film construction. The enhanced durability and heat dissipation of wire-wound designs enable better performance in environments with high thermal stress.

Precision and Tolerance Levels

Wire-wound resistors offer high precision with tolerance levels commonly around +-0.1% to +-1%, making them suitable for applications requiring stable resistance and accuracy over a wide range of temperatures. Thin-film resistors provide even tighter tolerance levels, often as low as +-0.01%, delivering superior precision and minimal temperature coefficient, ideal for sensitive electronic circuits. When your design requires ultra-precise resistance values and low drift, thin-film resistors are typically the preferred choice over wire-wound options.

Temperature Coefficient Analysis

Wire-wound resistors offer excellent temperature coefficient stability, typically around +-5 ppm/degC, making them ideal for high-precision applications where minimal resistance variation with temperature changes is critical. Thin-film resistors, while generally having a higher temperature coefficient ranging from +-25 to +-100 ppm/degC, provide better overall tolerance and are more suitable for compact, high-frequency circuits. Understanding these differences helps you select the right resistor type based on your circuit's temperature stability requirements and performance goals.

Frequency Response Characteristics

Wire-wound resistors exhibit excellent frequency response characteristics at low frequencies due to their low inductance and resistance values but tend to suffer from significant inductive reactance at higher frequencies, limiting their use in high-frequency applications. Thin-film resistors provide superior high-frequency performance with minimal inductance and capacitance, making them ideal for RF circuits and precision analog applications. Your choice should consider the operating frequency range, as thin-film resistors maintain stable resistance and minimal signal distortion across broader frequency bands compared to wire-wound types.

Typical Applications and Use Cases

Wire-wound resistors are typically used in high-power applications like power supplies, motor controls, and audio equipment, where precision and heat dissipation are critical. Thin-film resistors are preferred for low-noise, high-frequency circuits such as instrumentation amplifiers, medical devices, and telecommunications due to their stability and accuracy. Your choice depends on whether your application prioritizes power handling or precision in sensitive electronics.

Cost and Availability Factors

Wire-wound resistors typically have higher production costs due to their complex manufacturing process involving metal wire coiling, leading to less availability and higher pricing compared to thin-film resistors. Thin-film resistors benefit from automated semiconductor fabrication techniques, resulting in lower costs and widespread availability suitable for mass production. Your choice may depend on budget constraints and accessibility, with thin-film options generally offering a more economical and readily obtainable solution.

Choosing the Right Resistor for Your Project

Wire-wound resistors offer high power ratings and excellent precision, making them ideal for applications requiring durability and stability under high current conditions. Thin-film resistors provide superior accuracy, low noise, and better temperature coefficients, suitable for sensitive electronic circuits demanding tight tolerance. Selecting between wire-wound and thin-film resistors depends on factors such as power dissipation, precision requirements, size constraints, and the operating environment of your project.

wire-wound resistor vs thin-film resistor Infographic

electrown.com

electrown.com