Pneumatic transmitters rely on air pressure to send signals, offering simplicity and durability in harsh environments, while electronic transmitters provide higher accuracy and faster response times through digital communication. Explore this article to understand which transmitter type best suits your industrial application needs.

Table of Comparison

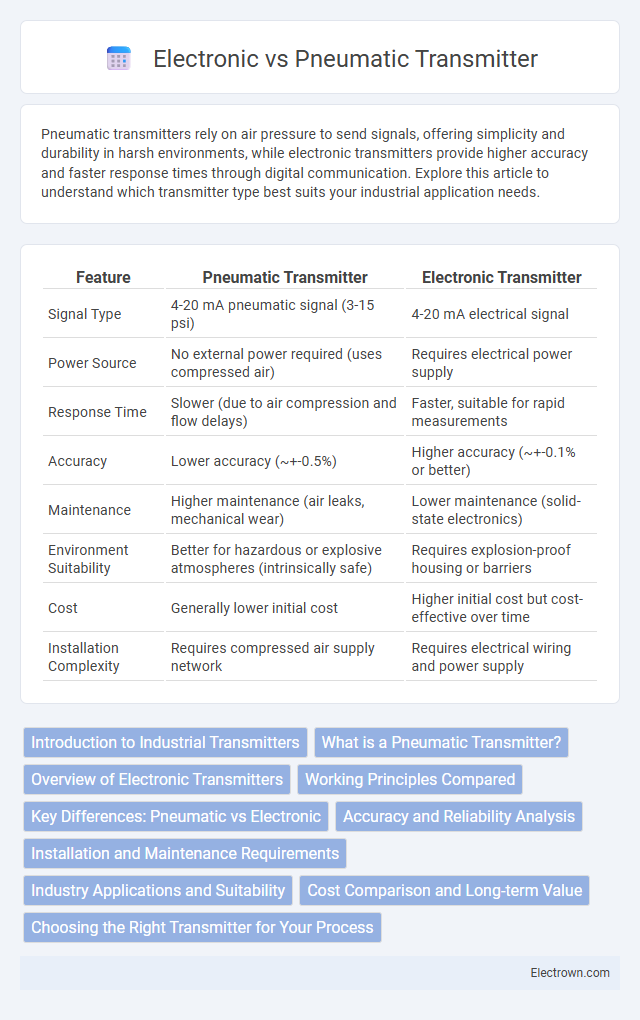

| Feature | Pneumatic Transmitter | Electronic Transmitter |

|---|---|---|

| Signal Type | 4-20 mA pneumatic signal (3-15 psi) | 4-20 mA electrical signal |

| Power Source | No external power required (uses compressed air) | Requires electrical power supply |

| Response Time | Slower (due to air compression and flow delays) | Faster, suitable for rapid measurements |

| Accuracy | Lower accuracy (~+-0.5%) | Higher accuracy (~+-0.1% or better) |

| Maintenance | Higher maintenance (air leaks, mechanical wear) | Lower maintenance (solid-state electronics) |

| Environment Suitability | Better for hazardous or explosive atmospheres (intrinsically safe) | Requires explosion-proof housing or barriers |

| Cost | Generally lower initial cost | Higher initial cost but cost-effective over time |

| Installation Complexity | Requires compressed air supply network | Requires electrical wiring and power supply |

Introduction to Industrial Transmitters

Industrial transmitters are essential devices in process automation, converting physical parameters such as pressure, temperature, or flow into standardized signals for monitoring and control. Pneumatic transmitters utilize compressed air to generate signals, offering simplicity and reliability in harsh environments, while electronic transmitters use electrical signals for higher accuracy and versatile integration with digital control systems. The choice between pneumatic and electronic transmitters depends on factors like operating conditions, signal transmission requirements, and maintenance preferences.

What is a Pneumatic Transmitter?

A pneumatic transmitter converts process variables such as pressure, temperature, or flow into a standardized pneumatic signal, usually 3-15 psi, for industrial control systems. It relies on compressed air to transmit the measured parameter over distance, making it highly reliable in hazardous or explosive environments where electrical signals might pose safety risks. Pneumatic transmitters are commonly used in industries like oil and gas, chemical processing, and power plants due to their simplicity, robustness, and resistance to electrical interference.

Overview of Electronic Transmitters

Electronic transmitters convert physical process variables such as pressure, temperature, or flow into standardized electrical signals, typically 4-20 mA, enabling precise and real-time data transmission. These devices integrate advanced microprocessor technology to improve accuracy, diagnostics, and communication capabilities compared to traditional pneumatic transmitters. Electronic transmitters support smart functions like self-calibration, remote monitoring, and compatibility with digital control systems such as SCADA and DCS for enhanced process automation and control.

Working Principles Compared

Pneumatic transmitters operate by converting process pressure into a corresponding pneumatic signal, typically ranging from 3 to 15 psi, using a mechanical or force-balance mechanism. Electronic transmitters utilize sensors and microprocessors to convert physical parameters into electrical signals, such as 4-20 mA, enabling higher accuracy and integration with digital systems. The fundamental difference lies in pneumatic transmitters relying on air pressure modulation, while electronic transmitters depend on electrical signal processing for measurement and communication.

Key Differences: Pneumatic vs Electronic

Pneumatic transmitters utilize air pressure signals for process measurement and control, making them ideal for hazardous environments due to their intrinsic safety and resistance to electrical interference. Electronic transmitters convert process variables into electrical signals, offering higher accuracy, faster response times, and easier integration with digital control systems like SCADA and DCS. The key differences lie in signal transmission method, maintenance complexity, and compatibility with modern automation technologies.

Accuracy and Reliability Analysis

Pneumatic transmitters offer moderate accuracy, typically around +-0.25% of span, and exhibit strong reliability in harsh, explosive environments due to their simple, mechanical design and lack of electrical components. Electronic transmitters provide higher accuracy, often within +-0.05% to +-0.1% of span, benefiting from advanced digital signal processing and enhanced linearity for precise measurements. Reliability in electronic transmitters depends on robust design and protection against electrical noise and power fluctuations, while pneumatic devices maintain consistent performance under extreme conditions without risk of electrical failure.

Installation and Maintenance Requirements

Pneumatic transmitters require compressed air supply lines and are generally more complex to install due to the need for air filters and regulators, increasing initial setup time. Electronic transmitters offer simpler installation with fewer components, often featuring plug-and-play connectors that reduce labor costs and downtime. Your maintenance demands for pneumatic systems include regular inspection and calibration of air supply, while electronic transmitters benefit from lower maintenance needs and easier diagnostics through digital interfaces.

Industry Applications and Suitability

Pneumatic transmitters excel in harsh industrial environments such as oil refineries and chemical plants due to their robustness and ability to operate without electrical power, making them ideal for intrinsically safe zones. Electronic transmitters offer higher precision and faster response times, suitable for industries requiring advanced data integration and remote monitoring, like pharmaceuticals and semiconductor manufacturing. Your choice depends on the specific industry application, environmental conditions, and the need for accuracy versus durability.

Cost Comparison and Long-term Value

Pneumatic transmitters generally have lower upfront costs compared to electronic transmitters due to simpler design and fewer components. Electronic transmitters, despite higher initial investment, offer greater accuracy, easier integration with modern control systems, and lower maintenance expenses, leading to superior long-term value. When evaluating total cost of ownership, electronic transmitters often provide better return on investment through enhanced performance and reduced downtime.

Choosing the Right Transmitter for Your Process

Selecting the right transmitter for your process depends on factors such as accuracy, response time, and environmental conditions. Pneumatic transmitters excel in hazardous environments with explosive gases due to their intrinsic safety and simplicity, whereas electronic transmitters offer higher precision, digital communication, and easier integration with modern control systems. Understanding your process requirements and operational constraints ensures your transmitter choice maximizes efficiency and reliability.

Pneumatic vs Electronic transmitter Infographic

electrown.com

electrown.com