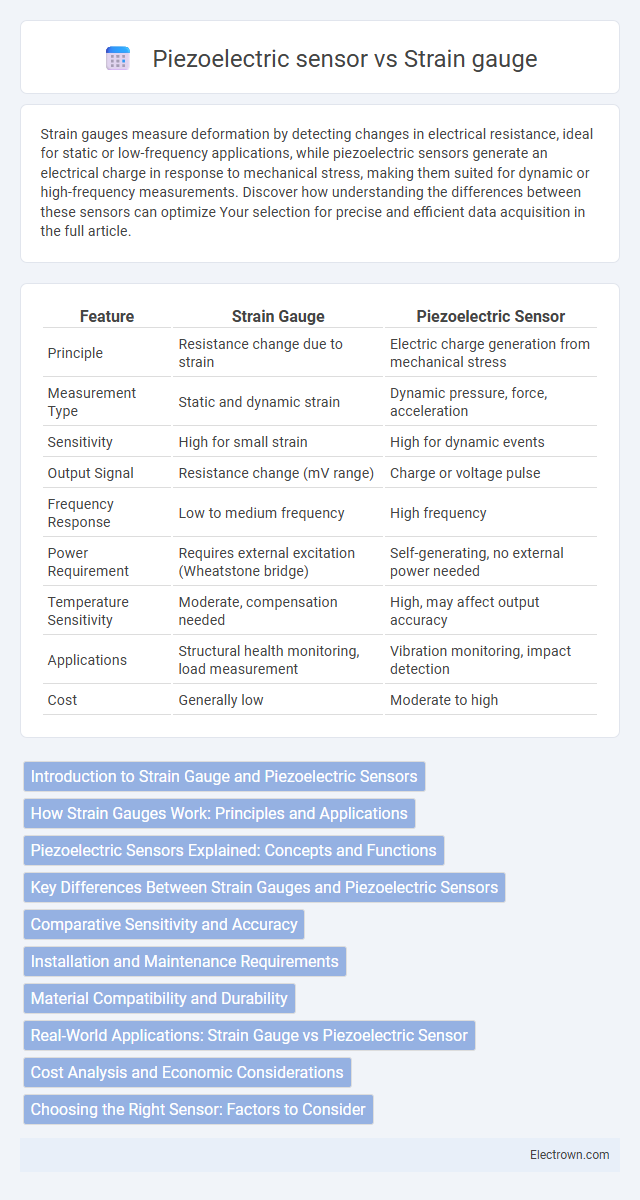

Strain gauges measure deformation by detecting changes in electrical resistance, ideal for static or low-frequency applications, while piezoelectric sensors generate an electrical charge in response to mechanical stress, making them suited for dynamic or high-frequency measurements. Discover how understanding the differences between these sensors can optimize Your selection for precise and efficient data acquisition in the full article.

Table of Comparison

| Feature | Strain Gauge | Piezoelectric Sensor |

|---|---|---|

| Principle | Resistance change due to strain | Electric charge generation from mechanical stress |

| Measurement Type | Static and dynamic strain | Dynamic pressure, force, acceleration |

| Sensitivity | High for small strain | High for dynamic events |

| Output Signal | Resistance change (mV range) | Charge or voltage pulse |

| Frequency Response | Low to medium frequency | High frequency |

| Power Requirement | Requires external excitation (Wheatstone bridge) | Self-generating, no external power needed |

| Temperature Sensitivity | Moderate, compensation needed | High, may affect output accuracy |

| Applications | Structural health monitoring, load measurement | Vibration monitoring, impact detection |

| Cost | Generally low | Moderate to high |

Introduction to Strain Gauge and Piezoelectric Sensors

Strain gauges measure deformation by detecting changes in electrical resistance when subjected to mechanical strain, making them ideal for static and low-frequency applications. Piezoelectric sensors generate an electrical charge in response to applied mechanical stress, offering high sensitivity and rapid response for dynamic or high-frequency measurements. Your choice between these sensors depends on the nature of the application, required sensitivity, and frequency range.

How Strain Gauges Work: Principles and Applications

Strain gauges operate by measuring the change in electrical resistance caused by deformation or strain on an object, using the principle that the resistance of a conductor varies with its length and cross-sectional area. These sensors are widely applied in structural health monitoring, load measurement, and material testing due to their high accuracy in detecting minute strain changes. If you need precise stress analysis, strain gauges provide reliable data essential for engineering and research applications.

Piezoelectric Sensors Explained: Concepts and Functions

Piezoelectric sensors operate by converting mechanical stress into an electrical charge through the piezoelectric effect, enabling precise measurement of dynamic pressure, force, and vibration. Unlike strain gauges, which detect deformation via resistance changes, piezoelectric sensors provide rapid response times and high sensitivity ideal for dynamic and transient signals. Their ability to generate charge without external power makes piezoelectric sensors essential in applications requiring high-frequency and high-accuracy monitoring.

Key Differences Between Strain Gauges and Piezoelectric Sensors

Strain gauges measure static and low-frequency strain by detecting changes in electrical resistance due to deformation, while piezoelectric sensors generate a voltage in response to dynamic pressure, vibration, or force, making them ideal for high-frequency applications. Strain gauges require external power and signal conditioning, whereas piezoelectric sensors produce their own electrical signal without needing a power supply. Your choice depends on whether you need to measure static loads with high accuracy (strain gauge) or dynamic changes in force and pressure (piezoelectric sensor).

Comparative Sensitivity and Accuracy

Strain gauges exhibit high sensitivity to static and low-frequency strain, providing precise and stable measurements ideal for structural monitoring. Piezoelectric sensors offer superior sensitivity to dynamic changes and transient forces but cannot measure static strain accurately due to charge leakage. The accuracy of strain gauges excels in long-term, steady-state conditions, whereas piezoelectric sensors deliver accurate dynamic response in applications involving vibrations or impact forces.

Installation and Maintenance Requirements

Strain gauges require precise surface preparation and bonding with adhesives, demanding careful alignment during installation to ensure accurate strain measurement, along with periodic recalibration to maintain performance. Piezoelectric sensors offer easier installation with minimal surface preparation, often requiring mounting with screws or adhesive tapes, and demonstrate low maintenance due to their robust materials and self-generating signal characteristics. Both sensor types necessitate consideration for environmental protection; strain gauges may require protective coatings, while piezoelectric sensors benefit from encapsulation to prevent damage from moisture or contaminants.

Material Compatibility and Durability

Strain gauges are typically made from metal foil or semiconductor materials, offering excellent material compatibility with a wide range of structural metals and alloys, making them ideal for long-term durability in static and low-frequency measurements. Piezoelectric sensors use crystals or ceramics such as quartz and PZT, providing high sensitivity but limited compatibility with materials that experience slow or static strain due to their inherent charge leakage over time. Your choice depends on the application's requirement for material binding and long-term reliability, where strain gauges excel in prolonged static environments while piezoelectric sensors perform better in dynamic, high-frequency conditions.

Real-World Applications: Strain Gauge vs Piezoelectric Sensor

Strain gauges are widely used in structural health monitoring, aerospace, and civil engineering to measure static or slowly varying strain with high accuracy. Piezoelectric sensors excel in dynamic applications such as vibration analysis, impact detection, and ultrasonic devices due to their ability to detect rapid changes in force or pressure. Your choice between these sensors depends on whether you need precise, steady-state strain measurements or fast response for transient events.

Cost Analysis and Economic Considerations

Strain gauges offer a cost-effective solution for static and low-frequency measurements due to their simple design and widespread availability, resulting in lower initial investment and maintenance expenses. Piezoelectric sensors, while typically more expensive upfront, provide superior sensitivity and durability in dynamic and high-frequency applications, which can lead to reduced long-term costs in specialized industries. Economic considerations should weigh the total cost of ownership, including installation, calibration, and operational lifespan, against the specific performance requirements of the sensing environment.

Choosing the Right Sensor: Factors to Consider

Choosing the right sensor between strain gauges and piezoelectric sensors depends on factors like measurement type, sensitivity, and application environment. Strain gauges excel in static and low-frequency strain measurements, offering high accuracy for monitoring structural deformation. Piezoelectric sensors are ideal for dynamic, high-frequency applications, providing rapid response and durability in harsh conditions, so your decision should align with the specific stress measurement requirements and operational constraints.

Strain gauge vs Piezoelectric sensor Infographic

electrown.com

electrown.com