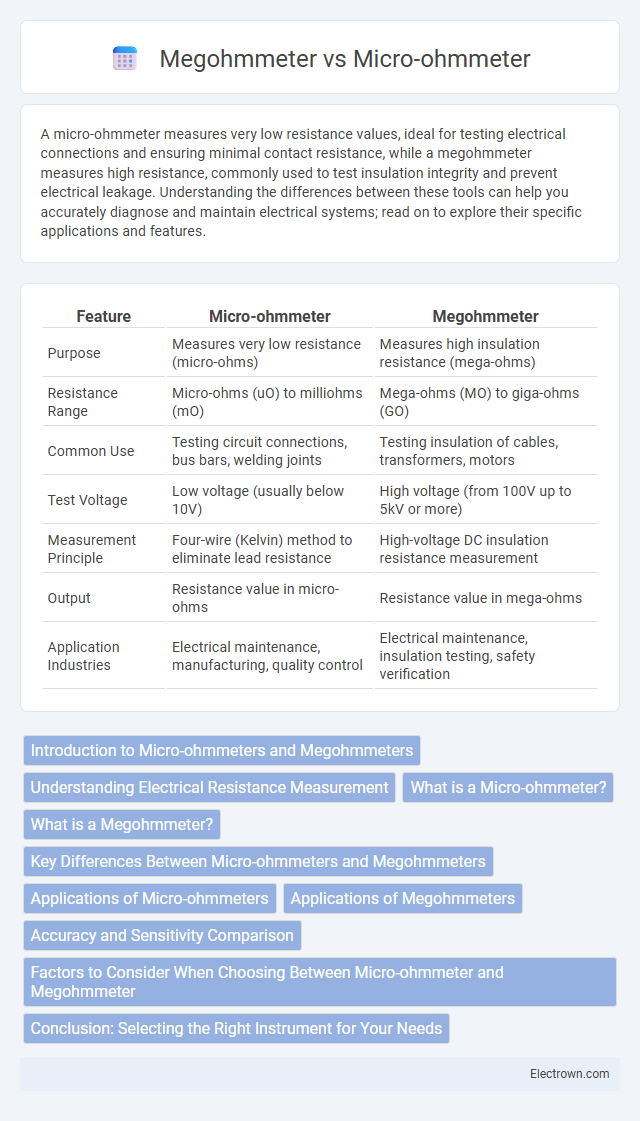

A micro-ohmmeter measures very low resistance values, ideal for testing electrical connections and ensuring minimal contact resistance, while a megohmmeter measures high resistance, commonly used to test insulation integrity and prevent electrical leakage. Understanding the differences between these tools can help you accurately diagnose and maintain electrical systems; read on to explore their specific applications and features.

Table of Comparison

| Feature | Micro-ohmmeter | Megohmmeter |

|---|---|---|

| Purpose | Measures very low resistance (micro-ohms) | Measures high insulation resistance (mega-ohms) |

| Resistance Range | Micro-ohms (uO) to milliohms (mO) | Mega-ohms (MO) to giga-ohms (GO) |

| Common Use | Testing circuit connections, bus bars, welding joints | Testing insulation of cables, transformers, motors |

| Test Voltage | Low voltage (usually below 10V) | High voltage (from 100V up to 5kV or more) |

| Measurement Principle | Four-wire (Kelvin) method to eliminate lead resistance | High-voltage DC insulation resistance measurement |

| Output | Resistance value in micro-ohms | Resistance value in mega-ohms |

| Application Industries | Electrical maintenance, manufacturing, quality control | Electrical maintenance, insulation testing, safety verification |

Introduction to Micro-ohmmeters and Megohmmeters

Micro-ohmmeters measure very low resistance values in the micro-ohm range, essential for assessing electrical connections, bonding, and contact resistance in industrial and automotive applications. Megohmmeters, also known as insulation testers, evaluate insulation resistance typically in the megohm range, crucial for ensuring the safety and reliability of electrical wiring and equipment. Understanding the difference between your micro-ohmmeter and megohmmeter helps optimize maintenance and troubleshooting processes by targeting specific resistance measurements.

Understanding Electrical Resistance Measurement

Micro-ohmmeters and megohmmeters measure electrical resistance within vastly different ranges, with micro-ohmmeters designed for low-resistance values typically in the micro-ohm (uO) range and megohmmeters measuring high resistance in the megohm (MO) range. Micro-ohmmeters are essential for assessing contact resistance, cable joints, and busbars to ensure minimal power loss and detect faults, while megohmmeters test insulation resistance in electrical equipment to prevent leakage currents and maintain safety standards. Understanding the specific resistance range and application requirements is critical for selecting the appropriate instrument for accurate electrical resistance measurement and effective maintenance.

What is a Micro-ohmmeter?

A Micro-ohmmeter measures extremely low electrical resistance, typically in the micro-ohm range, to detect minute resistance values in components like circuit breakers and connectors. It is essential for ensuring the integrity and performance of electrical connections by identifying potential faults caused by corrosion or loose contacts. Your ability to accurately assess these low resistance levels improves maintenance quality and prevents costly equipment failures.

What is a Megohmmeter?

A Megohmmeter, commonly known as an insulation resistance tester, measures high resistance values in electrical insulation, typically in the megohm range. It applies a high DC voltage, often between 250V and 5,000V, to assess the condition of insulation in cables, motors, and electrical equipment, ensuring safety and reliability. Megohmmeters are essential tools for detecting leaks, deterioration, or faults in insulating materials to prevent electrical hazards.

Key Differences Between Micro-ohmmeters and Megohmmeters

Micro-ohmmeters measure very low electrical resistance values, typically in the micro-ohm range, to detect minimal resistance in connections and components. Megohmmeters assess high resistance levels, often in the megaohm range, primarily used for insulation testing in electrical equipment. The key difference lies in their resistance measurement range and application focus, where micro-ohmmeters ensure proper conductivity and megohmmeters verify insulation integrity.

Applications of Micro-ohmmeters

Micro-ohmmeters are essential for measuring extremely low resistance values, typically in the micro-ohm range, making them ideal for applications such as testing electrical connections, circuit breakers, busbars, and transformer windings. These instruments ensure the integrity and reliability of critical components by detecting minute resistance changes that could indicate corrosion, loose connections, or faulty contacts in power distribution systems and electronics manufacturing. Your ability to accurately measure low resistance helps prevent equipment failures and maintain system efficiency.

Applications of Megohmmeters

Megohmmeters are primarily used for insulation resistance testing in electrical equipment such as transformers, motors, and cables, ensuring safety and reliability by detecting insulation degradation or faults. Their high-voltage measurement capability makes them essential in preventive maintenance and quality control across industries like power generation, manufacturing, and construction. Your ability to identify insulation failures with a megohmmeter helps prevent costly downtime and enhances operational safety.

Accuracy and Sensitivity Comparison

Micro-ohmmeters provide precise low-resistance measurements with high accuracy and sensitivity, ideal for detecting minute resistance changes in electrical connections. Megohmmeters excel at measuring high insulation resistance values, offering reliable sensitivity for detecting insulation degradation or faults. Your choice depends on whether you need to measure very low resistances with micro-ohm accuracy or assess insulation resistance in megohm ranges.

Factors to Consider When Choosing Between Micro-ohmmeter and Megohmmeter

Selecting between a micro-ohmmeter and a megohmmeter depends on the resistance measurement range and application requirements. Micro-ohmmeters are ideal for low-resistance measurements, such as contact resistance and connector testing, requiring precision in the micro-ohm range. Megohmmeters, on the other hand, specialize in high-resistance insulation testing, measuring resistance in the mega-ohm range to ensure electrical insulation integrity and safety.

Conclusion: Selecting the Right Instrument for Your Needs

Choosing between a micro-ohmmeter and a megohmmeter depends on the specific resistance measurement range required for your application. Micro-ohmmeters excel at detecting very low resistances, ideal for testing electrical connections and bonding, while megohmmeters measure high resistance levels, crucial for insulation testing and ensuring equipment safety. Understanding your testing environment and target resistance values ensures you select the right instrument for accurate and reliable results.

Micro-ohmmeter vs Megohmmeter Infographic

electrown.com

electrown.com