Class A RTDs offer higher accuracy with a tolerance of +-(0.15 + 0.002*|t|)degC, making them suitable for precise temperature measurements, while Class B RTDs have a wider tolerance of +-(0.3 + 0.005*|t|)degC and are commonly used in industrial applications where less precision is acceptable. Understanding these differences helps optimize Your temperature sensing solutions; explore the rest of the article for detailed comparisons and application guidance.

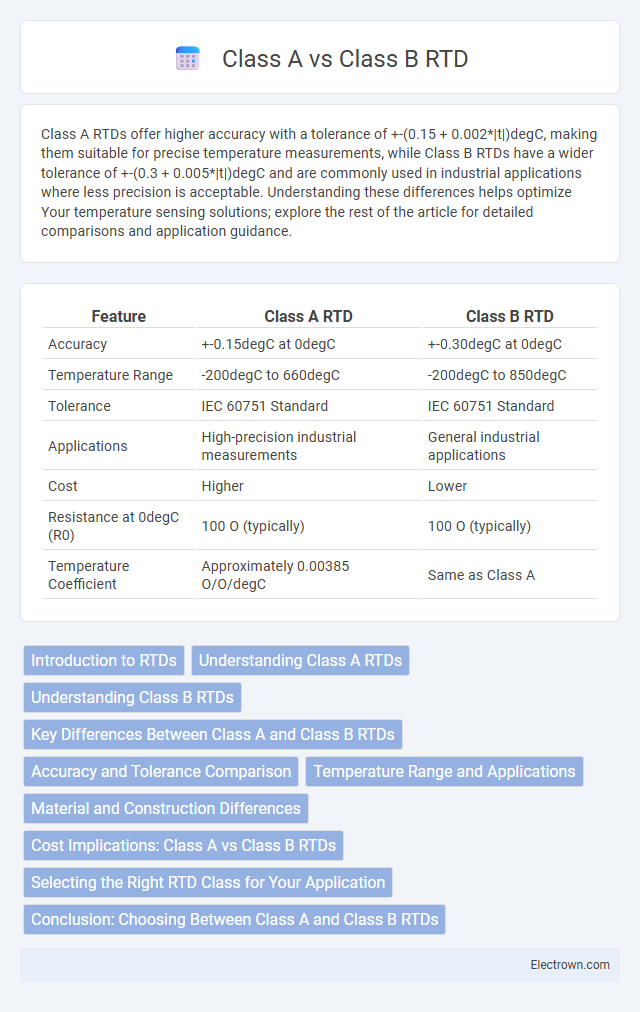

Table of Comparison

| Feature | Class A RTD | Class B RTD |

|---|---|---|

| Accuracy | +-0.15degC at 0degC | +-0.30degC at 0degC |

| Temperature Range | -200degC to 660degC | -200degC to 850degC |

| Tolerance | IEC 60751 Standard | IEC 60751 Standard |

| Applications | High-precision industrial measurements | General industrial applications |

| Cost | Higher | Lower |

| Resistance at 0degC (R0) | 100 O (typically) | 100 O (typically) |

| Temperature Coefficient | Approximately 0.00385 O/O/degC | Same as Class A |

Introduction to RTDs

Resistance Temperature Detectors (RTDs) are precision sensors that measure temperature by correlating the resistance of a metal element with temperature changes. Class A RTDs offer tighter tolerance and higher accuracy, typically +-(0.15 + 0.002*t) degC, making them ideal for applications demanding precise temperature control. Class B RTDs provide a broader tolerance of +-(0.30 + 0.005*t) degC, suitable for general industrial uses where less precision is acceptable, enabling users to select based on accuracy requirements and cost considerations.

Understanding Class A RTDs

Class A RTDs offer a tighter accuracy tolerance of +-0.15degC at 0degC, making them ideal for precise temperature measurements in industrial and laboratory settings. These sensors are constructed with high-purity platinum wire and are calibrated to meet stringent IEC 60751 standards, ensuring consistent and reliable readings. Their superior stability and resistance to drift distinguish Class A RTDs from Class B variants, which have a wider tolerance of +-0.30degC at 0degC.

Understanding Class B RTDs

Class B RTDs are standardized sensors with a tolerance of +-0.3degC at 0degC, making them less accurate but more cost-effective compared to Class A RTDs, which have a tighter tolerance of +-0.15degC. You can rely on Class B RTDs for general temperature measurements where high precision is not critical, such as in HVAC systems or process control applications. Their robust design and wider tolerance range make them suitable for industrial environments requiring dependable but economical temperature sensing.

Key Differences Between Class A and Class B RTDs

Class A and Class B RTDs differ mainly in accuracy and tolerance levels, with Class A offering tighter tolerances of +-(0.15 + 0.002 x t)degC compared to Class B's +-(0.30 + 0.005 x t)degC, making Class A suitable for precision measurements. Both classes operate under IEC 60751 standards, but Class A sensors provide superior stability and are preferred in critical temperature monitoring applications. Your selection depends on the required precision, with Class B providing more economical options for less stringent environments.

Accuracy and Tolerance Comparison

Class A RTDs offer higher accuracy with a tolerance of +-0.15degC at 0degC, making them suitable for precise temperature measurements. Class B RTDs have a wider tolerance of +-0.30degC at 0degC, providing reliable but less precise readings compared to Class A sensors. Your choice between Class A and Class B depends on the required accuracy level for your temperature sensing application.

Temperature Range and Applications

Class A RTDs offer a temperature range typically from -200degC to 600degC, making them suitable for precise temperature measurements in industrial processes requiring high accuracy and stability. Class B RTDs, with a broader range from -200degC to 850degC but lower accuracy, are preferred for applications involving higher temperatures such as furnace and kiln monitoring. Your choice depends on the temperature range and accuracy requirements specific to your application environment.

Material and Construction Differences

Class A RTDs typically use a platinum element with tighter tolerance and a resistance tolerance of +-0.15degC, offering higher accuracy and stability, while Class B RTDs have a wider tolerance of +-0.30degC and are often constructed with less stringent material standards. The construction of Class A sensors involves more precise winding of the platinum wire and better insulation to reduce measurement errors, enhancing your system's temperature sensing reliability. Selecting between Class A and Class B depends on the required measurement precision and environmental conditions, with Class A preferred for critical processes due to superior material purity and controlled assembly.

Cost Implications: Class A vs Class B RTDs

Class B RTDs offer a cost-effective solution with wider tolerance limits of +-0.6degC at 0degC, making them suitable for general industrial applications where precision is less critical. Class A RTDs provide higher accuracy with tighter tolerance limits of +-0.15degC at 0degC, which leads to increased manufacturing complexity and higher prices. Choosing between Class A and Class B RTDs involves balancing budget constraints against the precision requirements of the temperature measurement task.

Selecting the Right RTD Class for Your Application

Selecting the right RTD class depends on your application's accuracy requirements and environmental conditions; Class A RTDs offer higher precision with a tolerance of +-(0.15 + 0.002 * |t|) degC, suitable for laboratory or calibration tasks. Class B RTDs, with a tolerance of +-(0.30 + 0.005 * |t|) degC, provide robust performance for industrial processes where cost-effectiveness and durability are prioritized. Consider temperature range, measurement accuracy, and budget constraints to determine whether Class A's tighter tolerance or Class B's reliability aligns best with your specific measurement needs.

Conclusion: Choosing Between Class A and Class B RTDs

Class A RTDs offer higher accuracy and tighter tolerance, making them ideal for precision temperature measurements in critical industrial applications. Class B RTDs provide greater durability and cost-effectiveness while maintaining acceptable accuracy for general-purpose use. Your choice between Class A and Class B RTDs should depend on the specific accuracy requirements and budget constraints of your temperature sensing project.

Class A vs Class B RTD Infographic

electrown.com

electrown.com