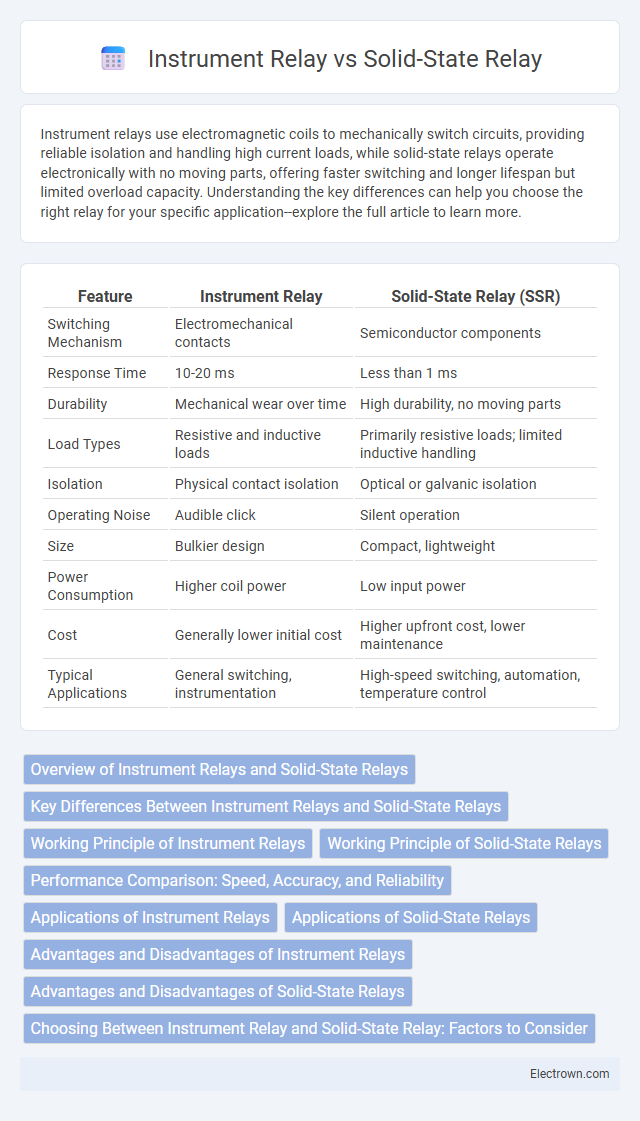

Instrument relays use electromagnetic coils to mechanically switch circuits, providing reliable isolation and handling high current loads, while solid-state relays operate electronically with no moving parts, offering faster switching and longer lifespan but limited overload capacity. Understanding the key differences can help you choose the right relay for your specific application--explore the full article to learn more.

Table of Comparison

| Feature | Instrument Relay | Solid-State Relay (SSR) |

|---|---|---|

| Switching Mechanism | Electromechanical contacts | Semiconductor components |

| Response Time | 10-20 ms | Less than 1 ms |

| Durability | Mechanical wear over time | High durability, no moving parts |

| Load Types | Resistive and inductive loads | Primarily resistive loads; limited inductive handling |

| Isolation | Physical contact isolation | Optical or galvanic isolation |

| Operating Noise | Audible click | Silent operation |

| Size | Bulkier design | Compact, lightweight |

| Power Consumption | Higher coil power | Low input power |

| Cost | Generally lower initial cost | Higher upfront cost, lower maintenance |

| Typical Applications | General switching, instrumentation | High-speed switching, automation, temperature control |

Overview of Instrument Relays and Solid-State Relays

Instrument relays are electromechanical devices designed to control high-power circuits using low-power signals, offering reliable isolation and precise switching in industrial applications. Solid-state relays use semiconductor components to switch electrical loads without moving parts, providing faster response times, longer lifespan, and minimal maintenance. Your choice between instrument relays and solid-state relays depends on factors like switching speed, load type, and reliability requirements.

Key Differences Between Instrument Relays and Solid-State Relays

Instrument relays utilize electromagnetic mechanisms to control circuit operations, providing precise switching with mechanical contacts that are ideal for high-current, high-voltage applications. Solid-state relays (SSRs) operate using semiconductor components like thyristors or triacs, offering faster switching speeds, longer lifespan, and resistance to shock and vibration due to the absence of moving parts. Key differences include durability, switching noise, response time, and application suitability, with instrument relays preferred for heavy-duty environments and SSRs favored for silent, rapid switching in low to medium power scenarios.

Working Principle of Instrument Relays

Instrument relays operate based on electromagnetic principles, where an input current or voltage generates a magnetic field that mechanically moves contacts to open or close a circuit. These relays rely on coil windings and armature assemblies to detect changes in electrical parameters and trigger switching actions. Unlike solid-state relays, instrument relays involve physical motion and mechanical contacts for circuit interruption or connection.

Working Principle of Solid-State Relays

Solid-state relays (SSRs) operate by using semiconductor devices such as thyristors, triacs, or transistors to switch electrical loads without moving parts, enabling faster and more reliable switching compared to electromechanical relays. SSRs isolate input and output circuits through optical coupling, ensuring minimal electrical noise and enhancing operational longevity in industrial automation and control systems. This solid-state switching principle results in increased durability, silent operation, and resistance to vibration and shock, making SSRs ideal for applications requiring frequent and rapid switching cycles.

Performance Comparison: Speed, Accuracy, and Reliability

Instrument relays provide superior accuracy and reliability in high-voltage, high-current applications due to their electromechanical construction, while solid-state relays (SSRs) excel in switching speed, offering millisecond response times with no mechanical wear. SSRs deliver consistent performance with minimal signal distortion, making them ideal for fast-switching control circuits, whereas instrument relays handle overload conditions better and offer clear physical indication of relay status. Your choice depends on prioritizing rapid response and noise immunity with SSRs or enhanced durability and precision in demanding industrial environments with instrument relays.

Applications of Instrument Relays

Instrument relays are widely used in industrial automation, power systems, and protective devices where precise control and reliable switching of electrical signals are crucial. These relays are ideal for applications involving measurement, monitoring, and control of instrumentation circuits, often found in transformers, motor protection, and utility automation. Your systems benefit from instrument relays due to their high sensitivity, accuracy, and ability to handle low-level signals without mechanical wear.

Applications of Solid-State Relays

Solid-state relays (SSRs) are widely used in industrial automation, HVAC systems, and temperature control applications due to their fast switching speeds and silent operation. They excel in environments requiring high durability and resistance to shock, vibration, and electrical noise, making them suitable for automotive and manufacturing machinery controls. SSRs also find applications in lighting systems, motor controls, and telecommunications where reliability and low electromagnetic interference are critical.

Advantages and Disadvantages of Instrument Relays

Instrument relays offer precise control and reliable isolation in electrical circuits, making them ideal for sensitive measurement and protection applications. You benefit from their robustness and ability to handle high voltages, but they may suffer from slower response times, mechanical wear, and larger physical size compared to solid-state relays. Maintenance requirements and susceptibility to vibration can be drawbacks when choosing instrument relays for critical or compact systems.

Advantages and Disadvantages of Solid-State Relays

Solid-state relays (SSRs) offer advantages such as faster switching speeds, longer operational life due to the absence of moving parts, and enhanced resistance to shock and vibration compared to instrument relays. They provide silent operation and lower electromagnetic interference, improving reliability in sensitive electronic environments. However, SSRs tend to have higher cost, reduced load current capacity, and heat generation requiring effective thermal management, which can impact your choice depending on the application requirements.

Choosing Between Instrument Relay and Solid-State Relay: Factors to Consider

Choosing between an instrument relay and a solid-state relay depends on factors such as load type, switching speed, durability, and electrical noise tolerance. Instrument relays excel in handling inductive loads and provide precise mechanical switching, making them ideal for applications requiring physical contact isolation. Solid-state relays offer faster switching times, longer lifespan due to lack of moving parts, and better performance in high-frequency environments, so your choice should align with the specific operational requirements of your system.

instrument relay vs solid-state relay Infographic

electrown.com

electrown.com