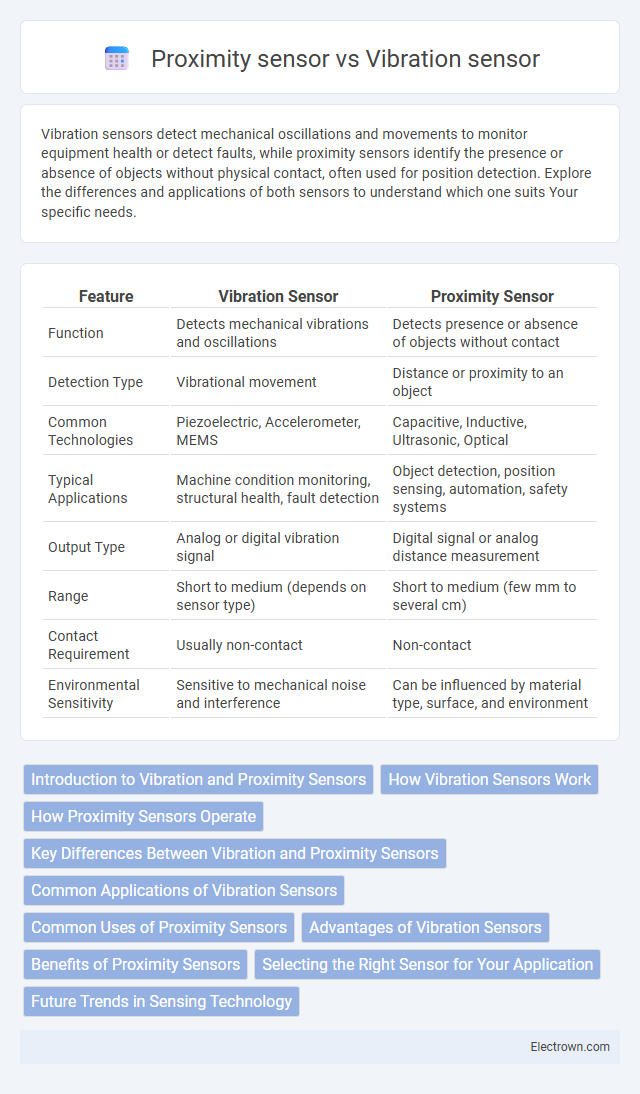

Vibration sensors detect mechanical oscillations and movements to monitor equipment health or detect faults, while proximity sensors identify the presence or absence of objects without physical contact, often used for position detection. Explore the differences and applications of both sensors to understand which one suits Your specific needs.

Table of Comparison

| Feature | Vibration Sensor | Proximity Sensor |

|---|---|---|

| Function | Detects mechanical vibrations and oscillations | Detects presence or absence of objects without contact |

| Detection Type | Vibrational movement | Distance or proximity to an object |

| Common Technologies | Piezoelectric, Accelerometer, MEMS | Capacitive, Inductive, Ultrasonic, Optical |

| Typical Applications | Machine condition monitoring, structural health, fault detection | Object detection, position sensing, automation, safety systems |

| Output Type | Analog or digital vibration signal | Digital signal or analog distance measurement |

| Range | Short to medium (depends on sensor type) | Short to medium (few mm to several cm) |

| Contact Requirement | Usually non-contact | Non-contact |

| Environmental Sensitivity | Sensitive to mechanical noise and interference | Can be influenced by material type, surface, and environment |

Introduction to Vibration and Proximity Sensors

Vibration sensors detect mechanical oscillations and are essential in monitoring equipment condition and structural health by measuring frequency and amplitude of vibrations. Proximity sensors detect the presence or absence of objects within a specified range without physical contact, commonly used in automation and safety systems. Both sensor types optimize industrial processes by enhancing predictive maintenance and improving operational efficiency.

How Vibration Sensors Work

Vibration sensors detect mechanical oscillations and convert them into electrical signals using piezoelectric, capacitive, or inductive principles, enabling real-time monitoring of equipment health. These sensors measure frequency, amplitude, and acceleration of vibrations to identify machinery imbalances, misalignments, or bearing failures. By leveraging vibration sensor data, you can predict maintenance needs and prevent unexpected downtime effectively.

How Proximity Sensors Operate

Proximity sensors operate by detecting the presence or absence of objects within a specific range without physical contact, often using electromagnetic fields, capacitance, or ultrasonic waves. Inductive proximity sensors sense metallic objects through changes in the electromagnetic field, while capacitive sensors detect both metallic and non-metallic materials by measuring changes in capacitance. Ultrasonic proximity sensors emit sound waves and measure the time taken for the echo to return, enabling accurate distance measurement even in challenging environments.

Key Differences Between Vibration and Proximity Sensors

Vibration sensors detect mechanical oscillations or movements in equipment, providing critical data for condition monitoring and predictive maintenance by measuring frequency and amplitude of vibrations. Proximity sensors, however, measure the presence or absence of an object within a specific range without physical contact, commonly using electromagnetic fields or capacitance. Understanding these key differences can help you select the right sensor type for applications involving motion detection or position sensing.

Common Applications of Vibration Sensors

Vibration sensors are extensively used in industrial machinery monitoring to detect imbalances, misalignments, and bearing failures, ensuring predictive maintenance and reducing downtime. They are crucial in automotive systems for engine and component health diagnostics and in consumer electronics for drop detection and device orientation. The ability to monitor structural health in buildings and bridges further highlights their significance in safety-critical applications.

Common Uses of Proximity Sensors

Proximity sensors are widely used in industrial automation for detecting the presence or absence of objects without physical contact, such as in assembly line monitoring and robotic arm positioning. They play a crucial role in mobile devices by enabling features like screen activation when held near the ear. Common applications also include security systems for motion detection and automotive systems for parking assistance and collision avoidance.

Advantages of Vibration Sensors

Vibration sensors offer precise monitoring of mechanical equipment by detecting slight oscillations and early signs of wear, enabling predictive maintenance and reducing downtime. Their sensitivity to various frequencies allows you to identify imbalances, misalignments, and bearing faults more effectively than proximity sensors, which primarily detect object presence or distance. This capability makes vibration sensors invaluable for enhancing operational efficiency and extending machinery lifespan.

Benefits of Proximity Sensors

Proximity sensors offer non-contact detection, enhancing durability and reducing wear compared to vibration sensors that rely on physical contact. They provide precise object detection and positioning in automated systems, crucial for maintaining operational efficiency and safety. Proximity sensors also excel in diverse environmental conditions, making them ideal for applications requiring reliable performance without mechanical interference.

Selecting the Right Sensor for Your Application

Vibration sensors excel in monitoring mechanical movements, detecting imbalances, and predicting equipment failures by measuring oscillations and frequency changes, making them ideal for rotating machinery and structural health applications. Proximity sensors detect the presence or absence of objects without physical contact, using technologies like inductive, capacitive, or ultrasonic sensing, best suited for object detection, positioning, and automation in manufacturing processes. Selecting the right sensor depends on application requirements such as detection range, environmental conditions, and the type of parameter to be measured--vibration sensors for dynamic condition monitoring, proximity sensors for spatial object detection.

Future Trends in Sensing Technology

Vibration sensors and proximity sensors are evolving with advances in IoT and AI, enabling more precise and predictive maintenance across industries. Future trends emphasize miniaturization, wireless connectivity, and enhanced data analytics to improve real-time monitoring capabilities. Your choice of sensor will benefit from ongoing innovations that increase accuracy, reduce energy consumption, and integrate seamlessly with smart systems.

Vibration sensor vs Proximity sensor Infographic

electrown.com

electrown.com