Drift compensation continuously corrects sensor output over time to maintain accuracy, while zero adjustment manually sets the baseline reading to zero before measurements begin. Understanding the differences can help you choose the right method for precise data monitoring--read on to explore their unique applications.

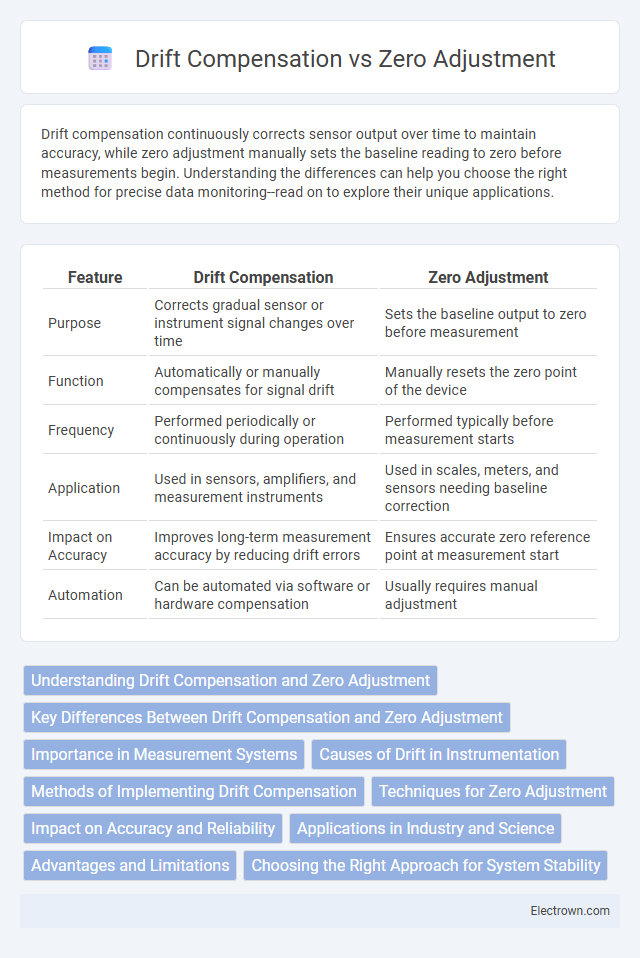

Table of Comparison

| Feature | Drift Compensation | Zero Adjustment |

|---|---|---|

| Purpose | Corrects gradual sensor or instrument signal changes over time | Sets the baseline output to zero before measurement |

| Function | Automatically or manually compensates for signal drift | Manually resets the zero point of the device |

| Frequency | Performed periodically or continuously during operation | Performed typically before measurement starts |

| Application | Used in sensors, amplifiers, and measurement instruments | Used in scales, meters, and sensors needing baseline correction |

| Impact on Accuracy | Improves long-term measurement accuracy by reducing drift errors | Ensures accurate zero reference point at measurement start |

| Automation | Can be automated via software or hardware compensation | Usually requires manual adjustment |

Understanding Drift Compensation and Zero Adjustment

Drift compensation continuously corrects measurement deviations caused by environmental changes or sensor aging, ensuring long-term accuracy in instrumentation. Zero adjustment, on the other hand, involves manually resetting the baseline measurement to a predefined zero point, eliminating initial offset errors. Understanding these processes helps you maintain precise and reliable sensor readings in various industrial applications.

Key Differences Between Drift Compensation and Zero Adjustment

Drift compensation automatically corrects gradual changes in sensor output due to environmental factors, ensuring long-term accuracy without manual intervention. Zero adjustment, on the other hand, is a manual process used to reset the sensor baseline or zero point to eliminate offset errors at a specific moment. While drift compensation maintains continuous calibration, zero adjustment is typically applied during initial setup or periodic maintenance.

Importance in Measurement Systems

Drift compensation is essential in measurement systems to maintain accuracy over time by correcting gradual sensor signal changes caused by environmental factors or aging. Zero adjustment ensures baseline calibration by resetting the sensor output to a true zero reference point, eliminating offset errors. Both techniques are critical for reliable data acquisition and precise measurement in industrial and scientific applications.

Causes of Drift in Instrumentation

Drift in instrumentation is primarily caused by environmental factors such as temperature fluctuations, humidity changes, and mechanical wear that affect sensor accuracy over time. Electronic component aging and power supply variations also contribute to baseline shifts, requiring regular drift compensation to maintain precise measurements. Zero adjustment corrects for initial offset errors but cannot address gradual signal changes caused by these persistent external influences.

Methods of Implementing Drift Compensation

Drift compensation is typically implemented using sensor calibration algorithms that continuously monitor and correct output signals to maintain accuracy over time, often involving digital filters and reference measurements. Zero adjustment, a simpler method, involves manually or automatically resetting the sensor output to a baseline value under known conditions to eliminate offset errors. Advanced drift compensation methods may incorporate temperature compensation, adaptive filtering, and machine learning models to dynamically correct sensor deviations in real-time.

Techniques for Zero Adjustment

Techniques for zero adjustment include manual calibration, automatic zeroing circuits, and software algorithms that correct baseline shifts in sensor outputs. Manual calibration typically involves physical adjustment of potentiometers or trim screws to reset the zero point, while automatic zeroing employs sensors that detect and compensate for offset in real-time to maintain accuracy. Software-based zero adjustment algorithms use digital filters and reference measurements to dynamically recalibrate the sensor output and minimize measurement errors caused by drift.

Impact on Accuracy and Reliability

Drift compensation significantly enhances the accuracy and reliability of measurement instruments by continuously correcting sensor deviations caused by environmental changes or aging, ensuring precise data over time. Zero adjustment, while useful for resetting the instrument baseline, addresses only instantaneous offset errors and cannot counteract ongoing drift, potentially compromising long-term measurement consistency. Your choice between these methods impacts overall system performance, with drift compensation providing superior stability and reliability in critical applications.

Applications in Industry and Science

Drift compensation is crucial in industrial sensor systems to maintain accurate measurements over time despite environmental changes, ensuring reliability in manufacturing process control and quality assurance. Zero adjustment is typically applied in scientific instrumentation to recalibrate devices at baseline conditions, enhancing precision in experiments requiring exact baseline data. Both techniques optimize sensor performance but address different error sources, making drift compensation ideal for dynamic industrial environments and zero adjustment essential for controlled scientific measurements.

Advantages and Limitations

Drift compensation enhances long-term measurement accuracy by automatically correcting sensor signal deviations caused by environmental changes, while zero adjustment provides a manual reset to baseline readings, ensuring immediate correction of offset errors. Drift compensation reduces maintenance frequency and human error but may introduce complexity in calibration protocols and potential delays in response. Zero adjustment is simple and quick, ideal for immediate correction, yet it requires frequent manual intervention and cannot address gradual sensor drift over time.

Choosing the Right Approach for System Stability

Drift compensation continuously corrects gradual sensor or system errors over time, maintaining real-time accuracy without interrupting operation. Zero adjustment resets the system baseline manually or automatically to eliminate offset errors, which is effective for addressing sudden shifts but may cause temporary downtime. You should choose drift compensation for ongoing stability in dynamic environments, while zero adjustment is better suited for periodic recalibration to ensure precise system performance.

drift compensation vs zero adjustment Infographic

electrown.com

electrown.com