Field transmitters are designed for installation directly in process environments, offering enhanced durability and resistance to harsh conditions, while panel mount transmitters are installed inside control panels for convenient monitoring and protection from environmental factors. Explore this article to understand which transmitter type best suits Your industrial automation needs.

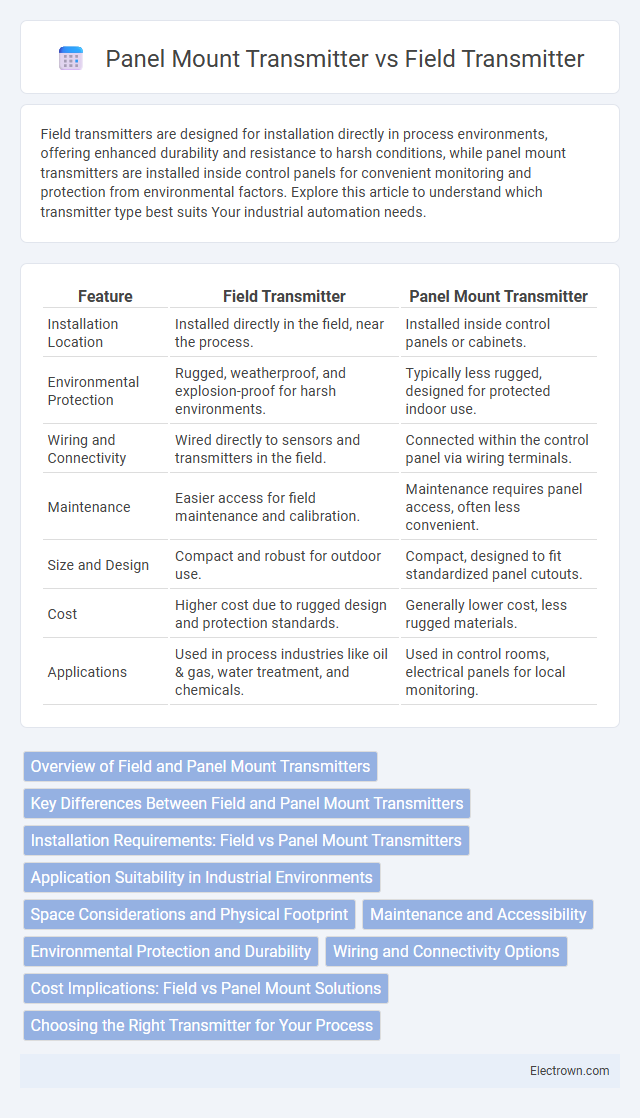

Table of Comparison

| Feature | Field Transmitter | Panel Mount Transmitter |

|---|---|---|

| Installation Location | Installed directly in the field, near the process. | Installed inside control panels or cabinets. |

| Environmental Protection | Rugged, weatherproof, and explosion-proof for harsh environments. | Typically less rugged, designed for protected indoor use. |

| Wiring and Connectivity | Wired directly to sensors and transmitters in the field. | Connected within the control panel via wiring terminals. |

| Maintenance | Easier access for field maintenance and calibration. | Maintenance requires panel access, often less convenient. |

| Size and Design | Compact and robust for outdoor use. | Compact, designed to fit standardized panel cutouts. |

| Cost | Higher cost due to rugged design and protection standards. | Generally lower cost, less rugged materials. |

| Applications | Used in process industries like oil & gas, water treatment, and chemicals. | Used in control rooms, electrical panels for local monitoring. |

Overview of Field and Panel Mount Transmitters

Field transmitters are rugged devices designed for installation directly in industrial environments, providing real-time process variable measurements such as pressure, temperature, or flow, with enhanced durability against harsh conditions. Panel mount transmitters are compact instruments installed on control panels, allowing easy access for calibration and monitoring, ideal for centralized control room applications. Your choice depends on installation requirements, environmental exposure, and ease of maintenance, with field transmitters favored for outdoor or remote locations and panel mount units suited for protected indoor settings.

Key Differences Between Field and Panel Mount Transmitters

Field transmitters are designed for direct installation in harsh environments outdoors, featuring rugged, weather-resistant housings and wireless communication capabilities, whereas panel mount transmitters are installed within control panels, providing easy access and protection from environmental factors. Field transmitters typically support remote monitoring and real-time data acquisition with robust surge protection, while panel mount transmitters prioritize integration with control systems and simplified wiring. The key differences lie in installation location, environmental durability, communication methods, and maintenance accessibility.

Installation Requirements: Field vs Panel Mount Transmitters

Field transmitters are designed for direct installation in harsh environmental conditions, featuring rugged enclosures that support weatherproof and explosive-proof standards, enabling easy integration on-site with minimal protective housing. Panel mount transmitters require precise cutouts within control panels or enclosures, demanding controlled environments to safeguard sensitive electronics and ensure easy access for calibration and maintenance. Installation of field transmitters emphasizes durable connections and external wiring, while panel mount transmitters focus on secure mounting and optimal internal layout within control cabinets.

Application Suitability in Industrial Environments

Field transmitters excel in harsh industrial environments due to their robust, weatherproof designs, making them ideal for outdoor or remote installations where exposure to extreme conditions is common. Panel mount transmitters are better suited for controlled indoor environments, such as control rooms or instrument panels, where protection from environmental elements is less critical and space-saving installation is required. Your choice depends on whether the application prioritizes durability and environmental resistance or compact integration within a protective enclosure.

Space Considerations and Physical Footprint

Field transmitters offer compact, rugged designs suitable for direct installation in outdoor or confined environments, minimizing space requirements on-site. Panel mount transmitters require dedicated space within control panels or enclosures, potentially increasing the overall footprint but offering easier access for maintenance. Selecting between them depends on the available installation space, environmental conditions, and ease of serviceability in industrial automation settings.

Maintenance and Accessibility

Field transmitters offer easier maintenance and accessibility since they are installed close to the process, allowing for quick inspection, calibration, and troubleshooting without the need to open control panels. Panel mount transmitters require accessing the control panel enclosure, which can slow down maintenance tasks and potentially expose sensitive electronics to environmental factors. You benefit from reduced downtime and improved operational efficiency with field transmitters due to their straightforward accessibility and servicing capabilities.

Environmental Protection and Durability

Field transmitters are designed with robust enclosures that offer high levels of environmental protection, such as IP67 or NEMA 4X ratings, ensuring durability in harsh outdoor conditions like rain, dust, and extreme temperatures. Panel mount transmitters, while typically housed inside control panels, rely on the panel's enclosure for protection, making them less resistant to direct exposure but still durable within controlled environments. Your choice depends on whether the transmitter needs to withstand direct environmental stress or operate in a protected, indoor setting.

Wiring and Connectivity Options

Field transmitters offer versatile wiring and connectivity options, typically supporting direct wiring to control systems or wireless communication protocols such as HART, Foundation Fieldbus, or WirelessHART for remote monitoring. Panel mount transmitters, designed for integration within control panels, usually feature terminal blocks or connector pins for simplified wiring, enabling streamlined connections to local display units or control circuits. Both types prioritize robust signal transmission, but field transmitters emphasize environmental protection and cable ingress ratings suitable for harsh outdoor conditions.

Cost Implications: Field vs Panel Mount Solutions

Field transmitters typically incur higher initial costs due to rugged enclosures and weatherproof certifications necessary for outdoor installation, while panel mount transmitters are generally more cost-effective, suited for controlled indoor environments. Maintenance expenses for field transmitters can be significant, given the need for specialized tools and accessibility challenges, whereas panel mount transmitters allow for easier, quicker servicing within control panels, reducing downtime. Your decision should balance upfront investment and long-term operational costs, considering the specific application environment and reliability requirements.

Choosing the Right Transmitter for Your Process

Field transmitters offer robust, weather-resistant designs ideal for outdoor or harsh industrial environments, ensuring accurate sensor data transmission over long distances. Panel mount transmitters are best suited for controlled indoor settings, providing easy integration into control panels with straightforward installation and maintenance. Selecting the right transmitter depends on environmental conditions, installation constraints, and the need for durability versus accessibility in your process control system.

Field transmitter vs Panel mount transmitter Infographic

electrown.com

electrown.com