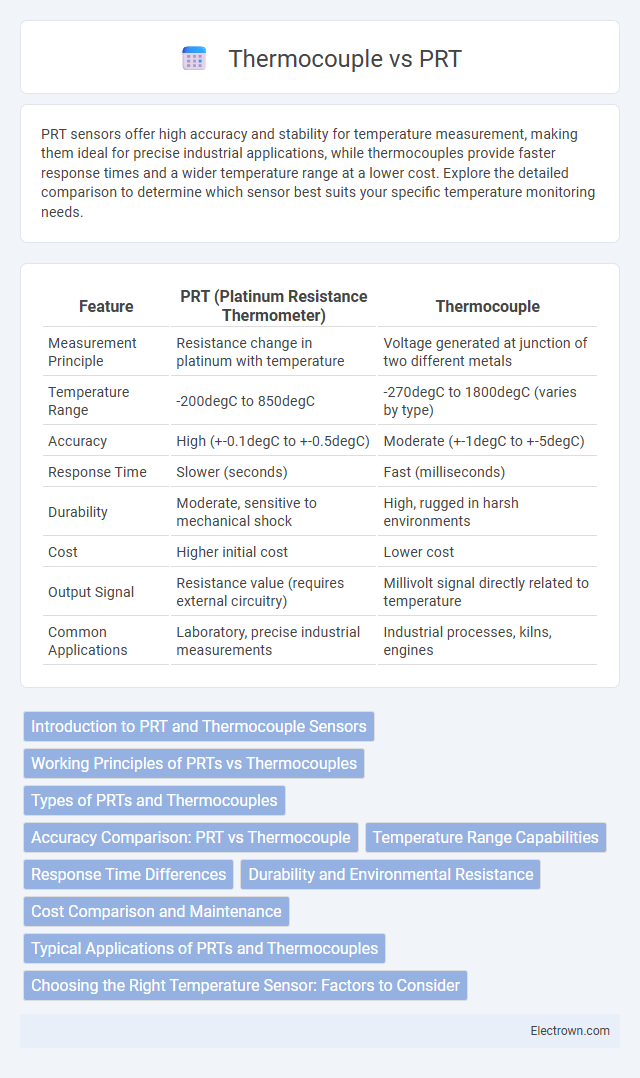

PRT sensors offer high accuracy and stability for temperature measurement, making them ideal for precise industrial applications, while thermocouples provide faster response times and a wider temperature range at a lower cost. Explore the detailed comparison to determine which sensor best suits your specific temperature monitoring needs.

Table of Comparison

| Feature | PRT (Platinum Resistance Thermometer) | Thermocouple |

|---|---|---|

| Measurement Principle | Resistance change in platinum with temperature | Voltage generated at junction of two different metals |

| Temperature Range | -200degC to 850degC | -270degC to 1800degC (varies by type) |

| Accuracy | High (+-0.1degC to +-0.5degC) | Moderate (+-1degC to +-5degC) |

| Response Time | Slower (seconds) | Fast (milliseconds) |

| Durability | Moderate, sensitive to mechanical shock | High, rugged in harsh environments |

| Cost | Higher initial cost | Lower cost |

| Output Signal | Resistance value (requires external circuitry) | Millivolt signal directly related to temperature |

| Common Applications | Laboratory, precise industrial measurements | Industrial processes, kilns, engines |

Introduction to PRT and Thermocouple Sensors

PRT (Platinum Resistance Thermometer) sensors measure temperature based on the predictable resistance change of platinum with temperature, offering high accuracy and stability over a wide range. Thermocouple sensors generate a voltage due to the Seebeck effect, created by joining two different metals, providing rapid response and a broad temperature measurement range. Your choice between PRT and thermocouple depends on requirements for precision, temperature range, and environmental conditions.

Working Principles of PRTs vs Thermocouples

PRTs (Platinum Resistance Thermometers) operate by measuring the change in electrical resistance of platinum wire as temperature varies, providing high accuracy through predictable resistance-temperature relationships. Thermocouples function based on the Seebeck effect, where a voltage is generated at the junction of two dissimilar metals when exposed to temperature differences, enabling wide-range temperature measurements. Your choice depends on whether you require the precision and stability of PRTs or the broader temperature range and faster response time of thermocouples.

Types of PRTs and Thermocouples

Platinum Resistance Thermometers (PRTs) include thin-film, wire-wound, and foil types, each offering high accuracy and stability for temperature measurement in industrial and scientific applications. Thermocouples come in various types such as Type K, Type J, and Type T, defined by their metal combinations and temperature ranges, making them versatile for high-temperature or rapid-response environments. Your choice between PRTs and thermocouples depends on temperature range, response time, and precision requirements.

Accuracy Comparison: PRT vs Thermocouple

PRTs (Platinum Resistance Thermometers) offer superior accuracy, typically within +-0.1degC, compared to thermocouples, which generally have accuracies ranging from +-1degC to +-2degC depending on type and calibration. PRTs maintain precision over a wide temperature range with better stability and repeatability, ideal for laboratory and industrial applications requiring exact temperature measurements. Your choice between PRT and thermocouple depends on the accuracy needs of your process, with PRTs preferred for high-precision tasks and thermocouples suited for broader temperature ranges and faster response times.

Temperature Range Capabilities

Platinum Resistance Thermometers (PRTs) typically operate effectively within a temperature range of -200degC to 850degC, making them suitable for high-precision measurements in moderate to high-temperature environments. Thermocouples, depending on type (e.g., Type K, J, or T), can measure a broader range, from approximately -270degC up to 1800degC, accommodating ultra-low to extreme high-temperature applications. The choice between PRTs and thermocouples hinges on the specific temperature span and accuracy requirements of the industrial or scientific measurement task.

Response Time Differences

Platinum Resistance Thermometers (PRTs) exhibit slower response times compared to thermocouples due to their larger sensor size and reliance on resistance measurement principles. Thermocouples respond rapidly to temperature changes because of their direct voltage generation from junctions of dissimilar metals, typically achieving response times in milliseconds. This makes thermocouples preferable for applications requiring fast temperature detection, while PRTs are favored for high-accuracy measurements despite their slower response.

Durability and Environmental Resistance

Platinum Resistance Thermometers (PRTs) offer superior durability and excellent resistance to harsh environments due to their robust metal construction and stable resistance-temperature relationship. Thermocouples, while generally more rugged and suitable for extreme temperatures up to 2300degC, can suffer from degradation and drift when exposed to oxidation, corrosive gases, or mechanical stress. The choice between PRTs and thermocouples depends on the application's environmental factors, with PRTs favored for stability in clean, moderate conditions and thermocouples preferred for high-temperature, electrically noisy, or chemically aggressive settings.

Cost Comparison and Maintenance

PRTs (Platinum Resistance Thermometers) generally have higher initial costs compared to thermocouples due to the use of precious metal elements and precise manufacturing processes. Thermocouples offer lower upfront expenses and simpler design, making them more cost-effective for many industrial applications. Maintenance for PRTs involves careful handling to prevent damage and periodic calibration for accuracy, while thermocouples require more frequent replacement due to sensor degradation but have minimal calibration needs.

Typical Applications of PRTs and Thermocouples

PRTs are commonly used in precision temperature measurements for laboratory experiments, industrial process control, and HVAC systems where accurate and stable readings are critical. Thermocouples excel in high-temperature environments such as furnaces, gas turbines, and engine testing due to their wide temperature range and rapid response. Your choice between PRTs and thermocouples depends on the required temperature accuracy, range, and environmental conditions of the application.

Choosing the Right Temperature Sensor: Factors to Consider

Selecting the right temperature sensor between PRT (Platinum Resistance Thermometer) and thermocouples depends on factors such as temperature range, accuracy requirements, and environmental conditions. PRTs offer high accuracy and stability within moderate temperature ranges (-200degC to 850degC), making them ideal for laboratory and industrial calibration. Thermocouples provide broader temperature measurement (-200degC to 2300degC) and faster response times, suited for high-temperature and rugged environments despite lower precision.

PRT vs Thermocouple Infographic

electrown.com

electrown.com