Electromagnetic flowmeters provide accurate measurements for conductive fluids by using Faraday's law of electromagnetic induction, whereas ultrasonic flowmeters use sound waves to determine flow velocity, suitable for both conductive and non-conductive fluids. Explore this article to understand which flowmeter best aligns with your measurement needs and application specifics.

Table of Comparison

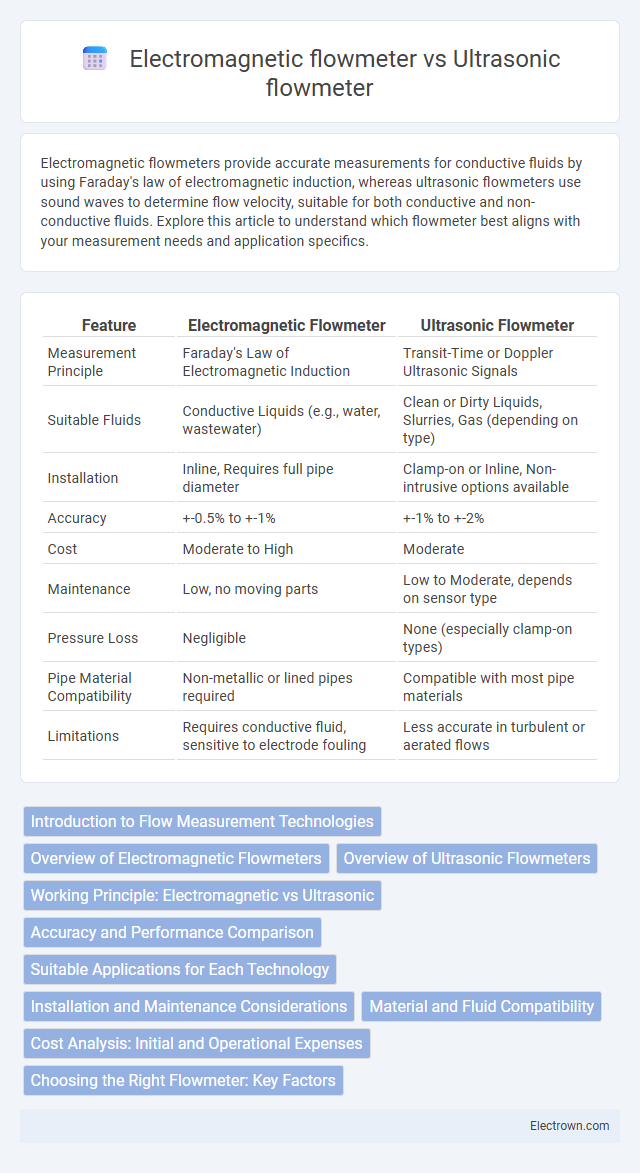

| Feature | Electromagnetic Flowmeter | Ultrasonic Flowmeter |

|---|---|---|

| Measurement Principle | Faraday's Law of Electromagnetic Induction | Transit-Time or Doppler Ultrasonic Signals |

| Suitable Fluids | Conductive Liquids (e.g., water, wastewater) | Clean or Dirty Liquids, Slurries, Gas (depending on type) |

| Installation | Inline, Requires full pipe diameter | Clamp-on or Inline, Non-intrusive options available |

| Accuracy | +-0.5% to +-1% | +-1% to +-2% |

| Cost | Moderate to High | Moderate |

| Maintenance | Low, no moving parts | Low to Moderate, depends on sensor type |

| Pressure Loss | Negligible | None (especially clamp-on types) |

| Pipe Material Compatibility | Non-metallic or lined pipes required | Compatible with most pipe materials |

| Limitations | Requires conductive fluid, sensitive to electrode fouling | Less accurate in turbulent or aerated flows |

Introduction to Flow Measurement Technologies

Electromagnetic flowmeters measure flow rate by detecting the voltage generated when conductive fluids move through a magnetic field, making them ideal for water, wastewater, and slurry applications. Ultrasonic flowmeters use the transit-time or Doppler principle to calculate flow velocity by measuring the time difference or frequency shift of ultrasonic pulses traveling through the fluid, suitable for clean and dirty liquids. Both technologies offer non-invasive, accurate flow measurement but differ in application scope, installation requirements, and fluid compatibility.

Overview of Electromagnetic Flowmeters

Electromagnetic flowmeters, also known as mag meters, measure the flow rate of conductive fluids by applying Faraday's Law of Electromagnetic Induction, generating a voltage proportional to fluid velocity. These flowmeters excel in accuracy and are widely used in water and wastewater treatment, chemical processing, and mining industries due to their non-intrusive design and absence of moving parts. They require conductive liquids for operation and offer advantages such as low maintenance, resistance to corrosion, and capability to handle dirty or abrasive fluids.

Overview of Ultrasonic Flowmeters

Ultrasonic flowmeters measure fluid velocity by transmitting high-frequency sound waves through the fluid and analyzing the Doppler shift or transit time difference. These flowmeters are non-intrusive, suitable for various pipe sizes, and can handle clean or slightly contaminated fluids with minimal pressure loss. Compared to electromagnetic flowmeters, ultrasonic flowmeters offer easier installation and maintenance without direct contact with the fluid.

Working Principle: Electromagnetic vs Ultrasonic

Electromagnetic flowmeters operate based on Faraday's law of electromagnetic induction, measuring the voltage generated when conductive fluid flows through a magnetic field, which correlates with flow velocity. Ultrasonic flowmeters utilize the transit-time or Doppler effect by sending ultrasonic waves through the fluid and analyzing the change in wave velocity or frequency caused by fluid movement. Your choice between these technologies depends on fluid conductivity, as electromagnetic flowmeters require conductive fluids, while ultrasonic flowmeters can measure flow in both conductive and non-conductive liquids.

Accuracy and Performance Comparison

Electromagnetic flowmeters provide high accuracy for conductive liquids, typically within +-0.2% to +-0.5% of the measured flow, excelling in applications with varying flow profiles and dirty or corrosive fluids. Ultrasonic flowmeters offer non-invasive measurement with accuracy generally around +-1% to +-2%, ideal for clean liquids and pipe installations where minimal pressure drop and no contact with the fluid are critical. Performance differences hinge on fluid conductivity and installation conditions, with electromagnetic flowmeters outperforming in precise measurement of aggressive or contaminated liquids, while ultrasonic flowmeters excel in maintenance-free, clamp-on applications.

Suitable Applications for Each Technology

Electromagnetic flowmeters excel in measuring conductive liquids such as water, wastewater, and slurries, making them ideal for municipal water treatment, chemical processing, and pulp and paper industries. Ultrasonic flowmeters are suitable for non-invasive measurement of clean liquids and gases, commonly used in HVAC systems, oil and gas pipelines, and food and beverage production. Choosing the right flowmeter depends on your fluid type, pipe material, and required measurement accuracy.

Installation and Maintenance Considerations

Electromagnetic flowmeters require conductive fluids and proper grounding for accurate installation, while ultrasonic flowmeters offer non-intrusive clamp-on options that simplify setup. Maintenance for electromagnetic flowmeters involves regular inspection of electrodes for fouling, whereas ultrasonic meters need periodic cleaning of transducer surfaces to maintain signal clarity. Your choice depends on the ease of installation and the long-term maintenance commitments suitable for your specific application.

Material and Fluid Compatibility

Electromagnetic flowmeters excel in measuring conductive fluids such as water, acids, and slurries, but require the fluid to have a minimum electrical conductivity to function accurately. Ultrasonic flowmeters, using sound waves, provide versatile compatibility with a wide range of fluids, including non-conductive liquids like oils and gases, and do not require direct contact with the fluid, reducing the risk of contamination. Your choice depends on the specific fluid properties and material compatibility, with electromagnetic models best suited for conductive fluids and ultrasonic models ideal for broader fluid types, including corrosive or dirty fluids.

Cost Analysis: Initial and Operational Expenses

Electromagnetic flowmeters typically demand higher initial investment due to their complex sensor technology and installation requirements but offer lower operational expenses with minimal maintenance and no moving parts. Ultrasonic flowmeters have a moderate initial cost, influenced by clamp-on or inline models, and incur varying operational expenses depending on sensor type and calibration frequency. Long-term cost efficiency favors electromagnetic flowmeters in conductive fluid applications, while ultrasonic flowmeters provide cost-effective solutions for non-conductive fluids or temporary installations.

Choosing the Right Flowmeter: Key Factors

Selecting the right flowmeter depends on fluid type, pipe material, and measurement accuracy requirements. Electromagnetic flowmeters are ideal for conductive liquids like water and slurries, offering high accuracy and minimal maintenance, but they require metal or lined pipes. Ultrasonic flowmeters suit a wide range of fluids, including non-conductive and corrosive fluids, provide non-intrusive measurements, and are preferred for applications requiring easy installation and versatility in pipe materials.

Electromagnetic flowmeter vs Ultrasonic flowmeter Infographic

electrown.com

electrown.com