Direct measurement involves obtaining data straight from the source or object without intermediate calculations, ensuring high accuracy and reliability. Understanding the differences between direct and indirect measurement will help you choose the best method for your specific needs--read on to learn more.

Table of Comparison

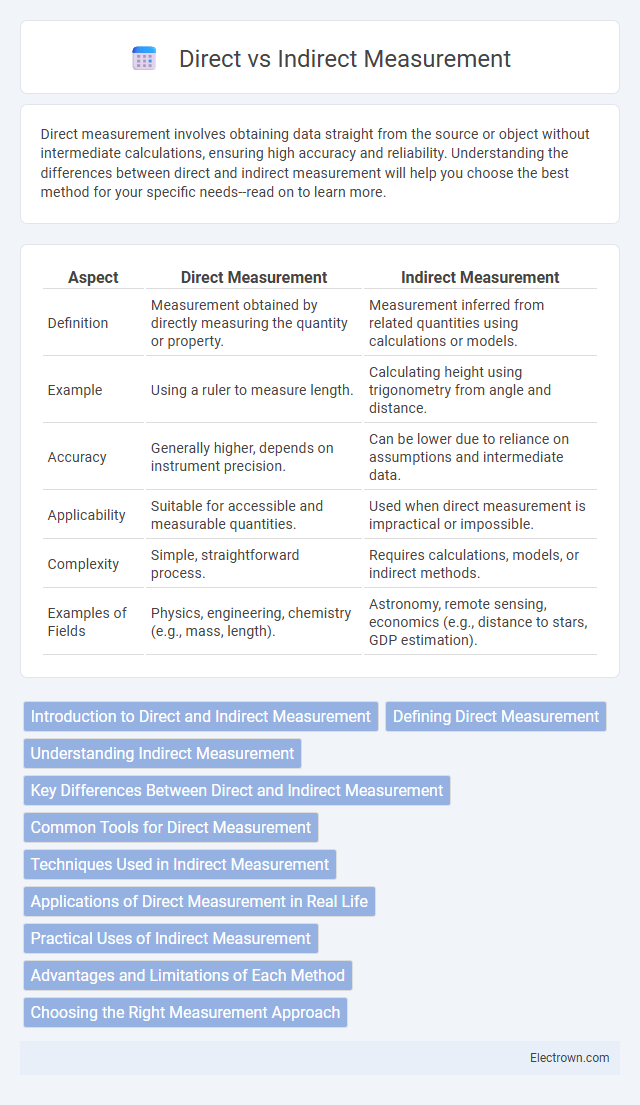

| Aspect | Direct Measurement | Indirect Measurement |

|---|---|---|

| Definition | Measurement obtained by directly measuring the quantity or property. | Measurement inferred from related quantities using calculations or models. |

| Example | Using a ruler to measure length. | Calculating height using trigonometry from angle and distance. |

| Accuracy | Generally higher, depends on instrument precision. | Can be lower due to reliance on assumptions and intermediate data. |

| Applicability | Suitable for accessible and measurable quantities. | Used when direct measurement is impractical or impossible. |

| Complexity | Simple, straightforward process. | Requires calculations, models, or indirect methods. |

| Examples of Fields | Physics, engineering, chemistry (e.g., mass, length). | Astronomy, remote sensing, economics (e.g., distance to stars, GDP estimation). |

Introduction to Direct and Indirect Measurement

Direct measurement involves obtaining data by physically measuring an object or quantity using tools like rulers, scales, or thermometers. Indirect measurement calculates values through mathematical relationships or formulas based on related known measurements, often employed when direct access is impractical. Your choice between direct and indirect measurement depends on factors such as accuracy requirements, accessibility, and the nature of the variable being measured.

Defining Direct Measurement

Direct measurement involves obtaining data by using physical tools or instruments to measure a quantity or characteristic directly from the object or phenomenon. Examples include measuring length with a ruler, temperature with a thermometer, or weight with a scale, providing precise and immediate values. This method reduces estimation errors compared to indirect measurement, where calculations or inferences are made based on related data.

Understanding Indirect Measurement

Indirect measurement uses tools like shadows, similar triangles, or proportional relationships to estimate lengths or distances that are difficult to measure directly. By applying mathematical principles such as trigonometry or ratios, you can calculate unknown values based on known measurements. This method is especially useful in fields like surveying, architecture, and astronomy where direct measurement is often impractical.

Key Differences Between Direct and Indirect Measurement

Direct measurement involves obtaining data through direct observation or instruments, providing precise and immediate values such as length measured with a ruler. Indirect measurement relies on calculations or inference from related quantities, like determining height using trigonometric relationships based on distance and angle. Understanding these key differences allows you to choose the most accurate and practical method depending on the context and available tools.

Common Tools for Direct Measurement

Common tools for direct measurement include rulers, calipers, micrometers, and tape measures, which provide accurate physical dimension readings. Vernier calipers and micrometers are especially valued for precision in engineering and manufacturing. These instruments enable straightforward data collection by physically interacting with the object being measured.

Techniques Used in Indirect Measurement

Techniques used in indirect measurement include triangulation, where distances or heights are calculated using angles and baseline measurements, and photogrammetry, which analyzes photographic images to estimate dimensions or spatial relationships. Other common methods involve the use of sensors or instruments that assess related physical properties, such as ultrasound or radar, to infer the desired quantity without direct contact. Your accurate data analysis depends on selecting the right indirect technique based on the environment and the precision required.

Applications of Direct Measurement in Real Life

Direct measurement is widely applied in construction, manufacturing, and healthcare to obtain accurate and immediate data such as length, weight, and temperature. Your ability to rely on precise tools like rulers, scales, and thermometers ensures quality control, safety compliance, and effective treatment outcomes. These practical applications emphasize the importance of direct measurement for making informed decisions in everyday professional and personal contexts.

Practical Uses of Indirect Measurement

Indirect measurement is essential in situations where direct measurement is impractical, dangerous, or impossible, such as determining the height of a tall building using shadow length and similar triangles or calculating distances across rivers with triangulation. It enables accurate results in surveying, astronomy, and physics without physical contact with the object or area being measured. Your ability to apply indirect measurement techniques can enhance efficiency and safety in construction, environmental studies, and navigation.

Advantages and Limitations of Each Method

Direct measurement offers high accuracy and immediate results by physically quantifying variables such as length, weight, or temperature, making it ideal for precise scientific experiments and quality control. However, it can be limited by practical constraints like accessibility, cost, and the potential for human error. Indirect measurement extends the capability to assess inaccessible or complex variables through calculations and models based on observable data, but it introduces uncertainty due to assumptions, approximations, and instrumental limitations.

Choosing the Right Measurement Approach

Choosing the right measurement approach depends on the accuracy required and the nature of the variable being measured. Direct measurement provides immediate and precise data by physically quantifying the attribute, ideal for straightforward parameters like length or weight. Indirect measurement uses related variables and calculations, beneficial when direct access is impossible or impractical, such as determining the height of a building using shadow length or trigonometrical methods.

Direct vs Indirect measurement Infographic

electrown.com

electrown.com