Panel meters provide fixed, precise readings integrated directly into equipment dashboards for continuous monitoring, while portable meters offer versatility and mobility for on-the-go measurements in various locations. Discover the key differences and determine which meter best suits your specific measurement needs by reading the full article.

Table of Comparison

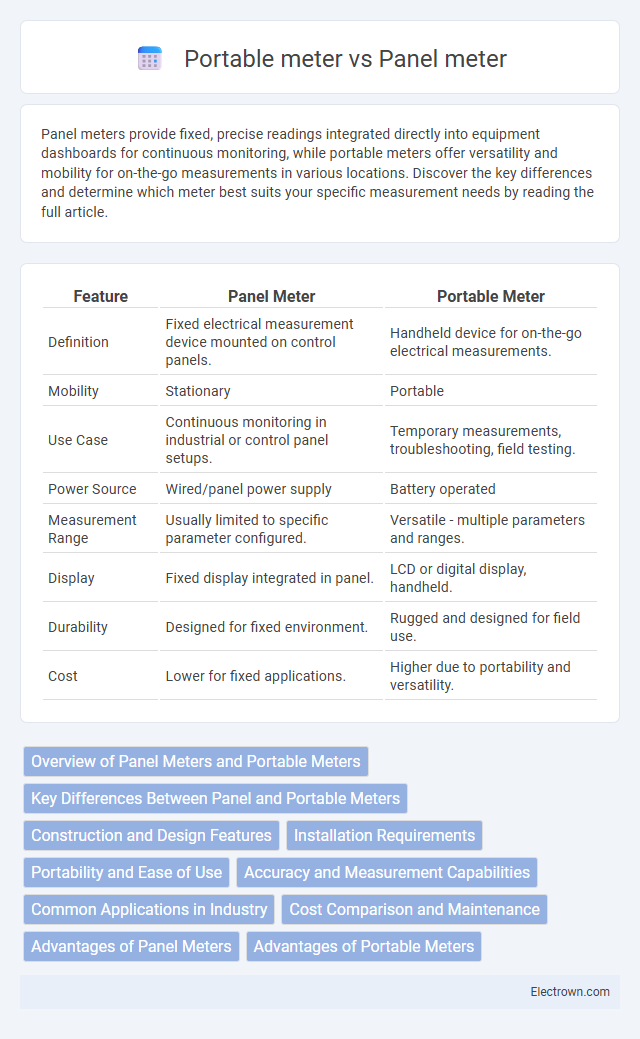

| Feature | Panel Meter | Portable Meter |

|---|---|---|

| Definition | Fixed electrical measurement device mounted on control panels. | Handheld device for on-the-go electrical measurements. |

| Mobility | Stationary | Portable |

| Use Case | Continuous monitoring in industrial or control panel setups. | Temporary measurements, troubleshooting, field testing. |

| Power Source | Wired/panel power supply | Battery operated |

| Measurement Range | Usually limited to specific parameter configured. | Versatile - multiple parameters and ranges. |

| Display | Fixed display integrated in panel. | LCD or digital display, handheld. |

| Durability | Designed for fixed environment. | Rugged and designed for field use. |

| Cost | Lower for fixed applications. | Higher due to portability and versatility. |

Overview of Panel Meters and Portable Meters

Panel meters are fixed electrical instruments designed for permanent installation on control panels, providing continuous monitoring of parameters such as voltage, current, or frequency. Portable meters are handheld devices that offer flexibility and convenience for on-the-go measurements across various locations, ideal for troubleshooting and temporary testing. Both types serve essential roles in electrical measurement, with panel meters emphasizing stationary monitoring and portable meters prioritizing mobility and versatility.

Key Differences Between Panel and Portable Meters

Panel meters are fixed instruments typically mounted on control panels, designed for continuous monitoring of electrical parameters such as voltage, current, or frequency within industrial systems. Portable meters offer mobility, allowing you to take precise measurements in varying locations and are ideal for troubleshooting and fieldwork due to their compact design and battery-powered operation. Key differences include installation permanence, measurement flexibility, power source, and usability in static versus dynamic environments.

Construction and Design Features

Panel meters typically feature a compact, fixed design integrated into control panels with robust enclosures for permanent installation and easy visibility, often including digital or analog displays. Portable meters prioritize lightweight, ergonomic construction with durable, shock-resistant casings and handheld interfaces for mobility and field use. Your choice depends on whether you need a stationary, easily monitored device or a versatile tool for varied measurement locations.

Installation Requirements

Panel meters require fixed mounting within control panels or machinery enclosures, ensuring permanent and stable installation with wiring connected directly to the system. Portable meters demand no fixed installation, allowing you to easily carry and connect them anywhere for quick measurements without altering existing setups. Your choice depends on whether you need a dedicated, permanent measurement solution or flexible, on-the-go testing capabilities.

Portability and Ease of Use

Portable meters offer superior portability and ease of use compared to panel meters, featuring compact, handheld designs that enable measurements in various locations without installation. Panel meters require fixed mounting within equipment or control panels, limiting mobility and often necessitating professional setup. Their user interfaces are typically less intuitive than portable meters, which often include digital displays, ergonomic buttons, and quick calibration features for field use.

Accuracy and Measurement Capabilities

Panel meters offer high accuracy with fixed calibration tailored for specific applications, ensuring consistent performance in controlled environments. Portable meters provide versatile measurement capabilities across various parameters but may exhibit slightly lower accuracy due to environmental variations and calibration flexibility. Selection depends on the need for precision versus adaptability in measurement tasks.

Common Applications in Industry

Panel meters are extensively used in industrial control panels for monitoring voltage, current, and temperature in automated manufacturing processes and power distribution systems. Portable meters are favored for on-site diagnostics, maintenance, and troubleshooting tasks across industries like electrical utilities, HVAC, and machinery repair. Your choice depends on whether continuous monitoring or flexible, handheld measurement is required in your industrial application.

Cost Comparison and Maintenance

Panel meters typically have a lower initial cost and require less frequent maintenance due to their fixed installation and robust design, making them cost-effective for long-term use in controlled environments. Portable meters often involve higher upfront expenses and ongoing maintenance due to their mobility, battery replacement, and calibration needs, which can increase total ownership costs. Your choice between these devices should consider both installation conditions and budget constraints related to maintenance and lifecycle expenses.

Advantages of Panel Meters

Panel meters offer superior integration for continuous monitoring within industrial control systems, enabling precise real-time data display directly on machinery or control panels. Their robust construction ensures durability and reliability in harsh environments, reducing maintenance needs and downtime. Space-saving design features allow seamless installation in confined panel spaces, optimizing facility layout and operational efficiency.

Advantages of Portable Meters

Portable meters offer unparalleled convenience and flexibility for on-the-go measurements in diverse environments, enabling quick diagnostics and real-time data collection without fixed installation. Their compact design and battery operation make them ideal for fieldwork or temporary setups, reducing downtime and enhancing operational efficiency. Advanced portable meters often feature wireless connectivity and multifunction capabilities, facilitating seamless data transfer and versatile usage across multiple applications.

Panel meter vs Portable meter Infographic

electrown.com

electrown.com