Linear potentiometers provide precise position feedback by converting linear displacement into an electrical signal, making them ideal for measuring straight-line motion, while rotary potentiometers measure angular displacement by tracking rotational movement. Explore this article to understand which potentiometer suits Your application needs best.

Table of Comparison

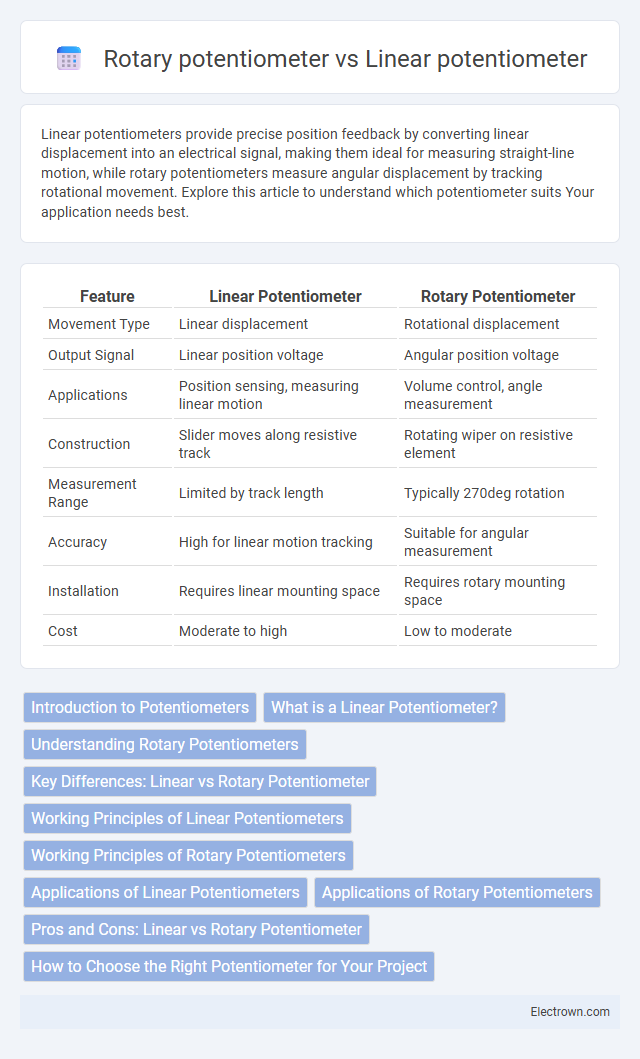

| Feature | Linear Potentiometer | Rotary Potentiometer |

|---|---|---|

| Movement Type | Linear displacement | Rotational displacement |

| Output Signal | Linear position voltage | Angular position voltage |

| Applications | Position sensing, measuring linear motion | Volume control, angle measurement |

| Construction | Slider moves along resistive track | Rotating wiper on resistive element |

| Measurement Range | Limited by track length | Typically 270deg rotation |

| Accuracy | High for linear motion tracking | Suitable for angular measurement |

| Installation | Requires linear mounting space | Requires rotary mounting space |

| Cost | Moderate to high | Low to moderate |

Introduction to Potentiometers

Potentiometers are variable resistors used to measure position or adjust electrical signals in circuits, available primarily in linear and rotary forms. Linear potentiometers provide straight-line motion detection, ideal for applications requiring precise displacement measurement along a single axis. Rotary potentiometers detect angular movement through a rotating shaft, commonly used in volume controls and tuning devices where rotational input is necessary.

What is a Linear Potentiometer?

A linear potentiometer is a type of position sensor that measures displacement by providing a variable resistance output proportional to the linear movement of its slider or wiper. Unlike rotary potentiometers, which rotate to change resistance, linear potentiometers track straight-line motion in applications such as robotics, industrial automation, and precision measurement. Your choice of a linear potentiometer ensures accurate feedback for systems requiring precise linear position sensing and control.

Understanding Rotary Potentiometers

Rotary potentiometers measure angular displacement by varying resistance as the shaft rotates, making them ideal for applications requiring rotational position feedback. Their design typically includes a circular resistive track and a rotating wiper, which differs from linear potentiometers that operate over straight-line movement. Understanding rotary potentiometers helps you select the right sensor for precise control in devices like volume knobs, steering angle sensors, and robotics.

Key Differences: Linear vs Rotary Potentiometer

Linear potentiometers measure displacement along a straight path, providing voltage output proportional to the position of a slider within a linear track, while rotary potentiometers detect angular displacement through rotation around a central axis, converting rotational movement into a corresponding voltage signal. Linear types offer precise linear position feedback ideal for applications like robotics and industrial measurement, whereas rotary potentiometers are preferred for controlling devices such as volume knobs and tuning dials due to their circular motion interface. The key difference lies in their movement mechanism--linear versus rotational--and their application suitability based on the geometry of the motion being measured or controlled.

Working Principles of Linear Potentiometers

Linear potentiometers operate by translating linear displacement into a variable electrical resistance, which changes proportionally to the position of a sliding wiper along a resistive track. This mechanism enables precise measurement of linear position or movement, making linear potentiometers ideal for applications requiring accurate linear feedback. Your choice between linear and rotary potentiometers depends on whether the measurement involves straight-line or rotational motion.

Working Principles of Rotary Potentiometers

Rotary potentiometers operate by converting angular displacement into a variable resistance output through a rotating shaft connected to a resistive element. The wiper moves along a circular track, adjusting resistance based on the shaft's rotation angle, which creates a voltage divider for precise voltage output control. This mechanism enables accurate measurement of angular position in applications like volume controls, joystick sensors, and motor feedback systems.

Applications of Linear Potentiometers

Linear potentiometers are widely used in applications requiring precise position feedback, such as industrial automation systems, robotics, and CNC machines. They excel in measuring linear displacement in hydraulic cylinders, automotive throttle position sensors, and medical devices for accurate motion control. These sensors provide reliable and repeatable linear position data essential for real-time monitoring and control in various engineering and manufacturing environments.

Applications of Rotary Potentiometers

Rotary potentiometers are widely used in applications requiring precise angular position sensing, such as volume control in audio equipment, tuning dials in radios, and feedback systems in robotics. Their ability to measure rotational displacement makes them ideal for joystick controls, motor speed adjustments, and automotive throttle position sensing. The versatility of rotary potentiometers extends to industrial machinery where rotational feedback ensures accurate control and monitoring.

Pros and Cons: Linear vs Rotary Potentiometer

Linear potentiometers offer precise position sensing with a straightforward, linear displacement output, making them ideal for applications requiring accurate measurements over a fixed range. Rotary potentiometers provide continuous rotational measurement and are compact, but may suffer from limited resolution and potential mechanical wear over time. Your choice depends on whether you need precise linear position tracking or a compact rotary control with less focus on linear accuracy.

How to Choose the Right Potentiometer for Your Project

Choosing the right potentiometer for your project depends on the application's mechanical requirements and signal control needs. Linear potentiometers provide precise displacement measurements, ideal for applications requiring straight-line sensing, while rotary potentiometers excel in measuring angular position or providing adjustable voltage within a rotating mechanism. Consider factors such as range of motion, resolution, electrical specifications, and installation constraints to determine whether a linear or rotary potentiometer best suits your project's performance and durability goals.

Linear potentiometer vs Rotary potentiometer Infographic

electrown.com

electrown.com