Nanorods and nanopillars are both nanoscale structures distinguished primarily by their shape and aspect ratio, with nanorods generally being elongated with a length much greater than their diameter, while nanopillars typically exhibit a more columnar, pillar-like form with a higher aspect ratio and vertical orientation. Understanding the differences in their physical properties and applications can help you determine which nanostructure best suits your needs; explore the rest of the article to learn more about their synthesis, characteristics, and use in cutting-edge technologies.

Table of Comparison

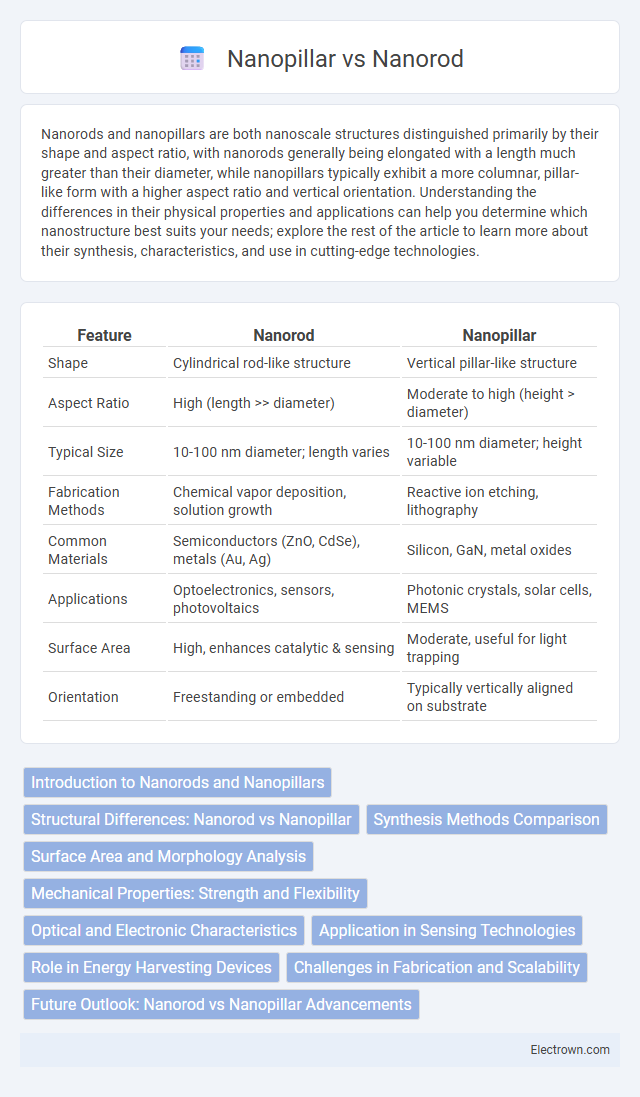

| Feature | Nanorod | Nanopillar |

|---|---|---|

| Shape | Cylindrical rod-like structure | Vertical pillar-like structure |

| Aspect Ratio | High (length >> diameter) | Moderate to high (height > diameter) |

| Typical Size | 10-100 nm diameter; length varies | 10-100 nm diameter; height variable |

| Fabrication Methods | Chemical vapor deposition, solution growth | Reactive ion etching, lithography |

| Common Materials | Semiconductors (ZnO, CdSe), metals (Au, Ag) | Silicon, GaN, metal oxides |

| Applications | Optoelectronics, sensors, photovoltaics | Photonic crystals, solar cells, MEMS |

| Surface Area | High, enhances catalytic & sensing | Moderate, useful for light trapping |

| Orientation | Freestanding or embedded | Typically vertically aligned on substrate |

Introduction to Nanorods and Nanopillars

Nanorods and nanopillars are nanoscale structures with distinct morphologies and applications in nanotechnology. Nanorods typically have an elongated, rod-like shape with diameters in the range of 1-100 nm and lengths extending up to several micrometers, offering high surface area and anisotropic properties for use in sensors, catalysts, and optoelectronic devices. Nanopillars are vertical, pillar-shaped nanostructures often fabricated on substrates, enabling enhanced light trapping, mechanical stability, and surface functionalization in photovoltaics, biomedical devices, and nanoelectronics.

Structural Differences: Nanorod vs Nanopillar

Nanorods typically feature a cylindrical shape with a high aspect ratio, characterized by a uniform diameter along their length, whereas nanopillars often present a tapered or conical structure with varying diameters from base to tip. Nanorods possess well-defined crystalline facets that influence their optical and electronic properties, while nanopillars exhibit anisotropic surface morphologies due to their substrate-anchored growth. These structural differences significantly impact their applications in photonics, sensing, and catalysis by affecting light absorption, charge carrier dynamics, and surface reactivity.

Synthesis Methods Comparison

Nanorods are typically synthesized using solution-phase methods such as seed-mediated growth and hydrothermal processes, providing precise control over length and diameter. Nanopillars are commonly fabricated via top-down approaches like reactive ion etching and nanoimprint lithography, enabling high aspect ratio and ordered arrays on substrates. Both methods influence the structural uniformity and surface properties critical for applications in optics and electronics.

Surface Area and Morphology Analysis

Nanorods exhibit a higher surface area-to-volume ratio compared to nanopillars due to their elongated cylindrical morphology, enhancing catalytic and sensor applications. Nanopillars possess a more uniform and densely packed morphology, which provides structural stability but may limit accessible surface area. Your choice between nanorods and nanopillars should consider the trade-off between maximizing surface interactions and maintaining mechanical robustness.

Mechanical Properties: Strength and Flexibility

Nanorods exhibit enhanced mechanical strength due to their elongated crystalline structure, which allows for efficient load distribution along their length, making them highly resistant to deformation. Nanopillars, characterized by their vertical, pillar-like shape, often demonstrate superior flexibility and resilience under bending stresses, attributed to their aspect ratio and surface-to-volume ratio. Both nanostructures exhibit unique mechanical properties optimized for different applications, with nanorods favored in high-strength environments and nanopillars excelling in flexible, responsive systems.

Optical and Electronic Characteristics

Nanorods exhibit anisotropic optical properties with tunable plasmonic resonances that enhance light absorption and emission, making them ideal for photonic and sensing applications. Nanopillars provide enhanced electron transport and reduced recombination rates due to their ordered vertical alignment, improving efficiency in electronic and photovoltaic devices. Your choice between nanorod and nanopillar structures depends on optimizing optical performance versus electronic conductivity for targeted nanotechnology applications.

Application in Sensing Technologies

Nanorods and nanopillars exhibit distinct morphologies that significantly impact their performance in sensing technologies, with nanorods offering enhanced surface area and improved electron transport for electrochemical sensors. Nanopillars, characterized by their high aspect ratio and vertical alignment, enable increased light absorption and sensitivity in optical sensors such as surface-enhanced Raman spectroscopy (SERS). Both nanostructures improve sensor sensitivity and response time, yet the choice depends on specific sensing requirements like target analyte type and detection environment.

Role in Energy Harvesting Devices

Nanorods and nanopillars play crucial roles in enhancing the efficiency of energy harvesting devices by improving light absorption and charge carrier transport. Nanorods, with their high aspect ratio and anisotropic structure, offer increased surface area and directional charge conduction, optimizing photovoltaic and photocatalytic performance. Nanopillars provide uniform light trapping and facilitate efficient electron-hole separation, making them essential in perovskite solar cells and piezoelectric nanogenerators.

Challenges in Fabrication and Scalability

Nanorod and nanopillar fabrication both face challenges in maintaining uniformity and precision at the nanoscale, impacting scalability for industrial applications. Nanorods often require complex synthesis methods like vapor-liquid-solid growth, leading to variability in length and diameter, whereas nanopillars typically involve top-down lithographic processes that can be time-consuming and costly. Understanding these fabrication nuances is crucial for optimizing Your production workflows in nanotechnology industries.

Future Outlook: Nanorod vs Nanopillar Advancements

Nanorod and nanopillar advancements continue to drive innovations in nanotechnology, with nanorods offering superior optical and electronic properties for applications in photovoltaics and sensors. Nanopillars provide enhanced surface area and mechanical stability, making them ideal for next-generation energy storage and biosensing devices. Your choice between these nanostructures will depend on the specific application requirements and the evolving material engineering breakthroughs.

Nanorod vs Nanopillar Infographic

electrown.com

electrown.com