Ternary alloys contain three different elements, offering enhanced mechanical properties and corrosion resistance compared to binary alloys, which consist of only two elements. Discover how choosing between these alloys can impact Your material performance by reading the full article.

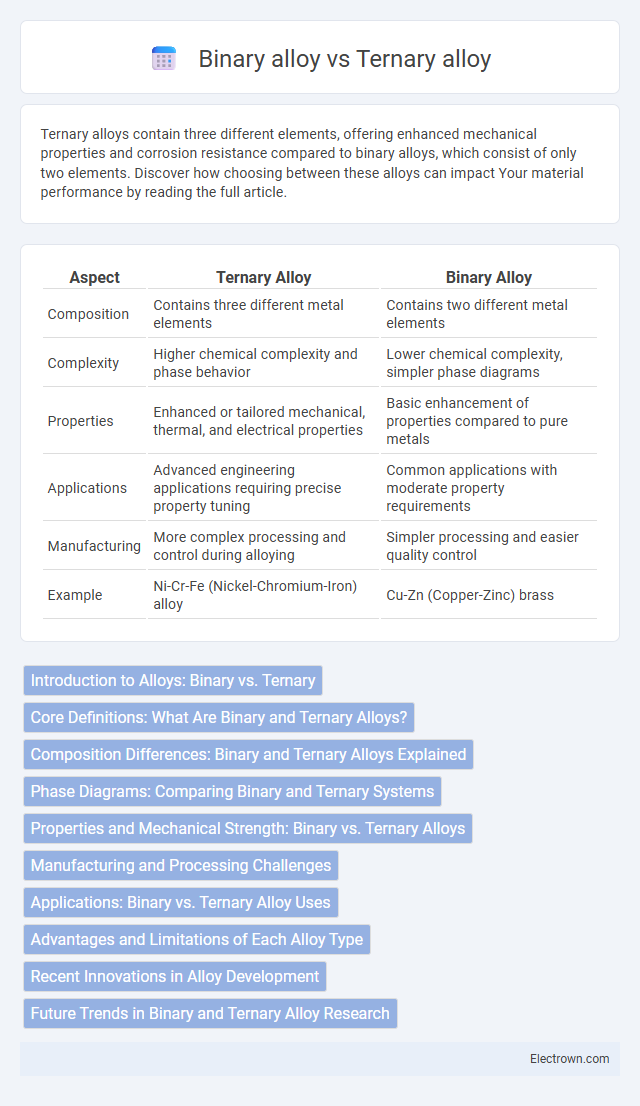

Table of Comparison

| Aspect | Ternary Alloy | Binary Alloy |

|---|---|---|

| Composition | Contains three different metal elements | Contains two different metal elements |

| Complexity | Higher chemical complexity and phase behavior | Lower chemical complexity, simpler phase diagrams |

| Properties | Enhanced or tailored mechanical, thermal, and electrical properties | Basic enhancement of properties compared to pure metals |

| Applications | Advanced engineering applications requiring precise property tuning | Common applications with moderate property requirements |

| Manufacturing | More complex processing and control during alloying | Simpler processing and easier quality control |

| Example | Ni-Cr-Fe (Nickel-Chromium-Iron) alloy | Cu-Zn (Copper-Zinc) brass |

Introduction to Alloys: Binary vs. Ternary

Binary alloys consist of two different elements combined to enhance mechanical properties and corrosion resistance, commonly used in industries like aerospace and automotive. Ternary alloys incorporate three elements, offering greater complexity and tailored characteristics such as improved strength, ductility, and thermal stability for specialized applications. Comparing these, ternary alloys provide enhanced versatility and performance due to the synergistic effects of three constituents versus the simpler composition of binary alloys.

Core Definitions: What Are Binary and Ternary Alloys?

Binary alloys consist of two distinct metallic elements combined to form a homogeneous mixture, enhancing properties such as strength, corrosion resistance, and electrical conductivity. Ternary alloys incorporate three different metallic elements, allowing for more precise tuning of physical and chemical characteristics, including improved hardness and thermal stability. The addition of a third component in ternary alloys enables the development of advanced materials with complex microstructures tailored for specific industrial applications.

Composition Differences: Binary and Ternary Alloys Explained

Binary alloys consist of two elements combined to create a material with enhanced mechanical properties, corrosion resistance, or thermal stability, commonly seen in alloys like bronze (copper and tin) or brass (copper and zinc). Ternary alloys incorporate three distinct elements, allowing for more complex microstructures and tailored properties, such as increased strength and improved corrosion resistance, exemplified by stainless steel variants containing iron, chromium, and nickel. The addition of the third element in ternary alloys significantly influences phase behavior and solidification processes, enabling customization of alloys for specific industrial applications.

Phase Diagrams: Comparing Binary and Ternary Systems

Phase diagrams for binary alloys illustrate the equilibrium between two components, detailing phase boundaries and compositions at varying temperatures. Ternary alloy phase diagrams add complexity by incorporating a third component, often represented in three-dimensional plots or triangular diagrams to capture multi-phase regions and compositional variations. Your understanding of material behavior improves by analyzing ternary phase diagrams, which provide more comprehensive insights into phase stability and transformations compared to binary systems.

Properties and Mechanical Strength: Binary vs. Ternary Alloys

Binary alloys, composed of two elements, typically exhibit simpler microstructures that provide predictable mechanical strength and properties such as hardness and ductility. Ternary alloys, with three elements, offer enhanced tunability in mechanical strength and properties by enabling complex phase formations and solid solution strengthening mechanisms. This increased compositional complexity in ternary alloys often results in superior performance, including improved tensile strength, corrosion resistance, and thermal stability compared to binary alloys.

Manufacturing and Processing Challenges

Ternary alloys present more complex manufacturing and processing challenges than binary alloys due to the necessity of precisely controlling three different elemental compositions, which impacts phase stability and microstructure uniformity. The presence of multiple alloying elements in ternary systems demands advanced techniques such as vacuum induction melting and rapid solidification to minimize segregation and phase separation. Your production process must account for these factors to ensure consistent mechanical properties and avoid defects during solidification or heat treatment stages.

Applications: Binary vs. Ternary Alloy Uses

Binary alloys, composed of two elements, are widely used in applications such as electrical wiring, plumbing, and lightweight structural components due to their simplified composition and predictable properties. Ternary alloys, containing three elements, offer enhanced mechanical strength, corrosion resistance, and tailored electrical characteristics that make them ideal for advanced aerospace components, high-performance electronics, and specialty medical devices. Your choice between binary and ternary alloys depends on the specific performance requirements and environmental conditions of the application.

Advantages and Limitations of Each Alloy Type

Ternary alloys offer enhanced mechanical properties and corrosion resistance by combining three elements, enabling tailored performance for specialized applications, but their complex phase diagrams can lead to unpredictable microstructures and higher production costs. Binary alloys provide simpler composition control and well-understood phase behavior, facilitating easier manufacturing and affordability, while their limited elemental diversity can restrict property optimization. Both alloy types require careful selection based on the balance between desired physical properties and processing feasibility for specific industrial uses.

Recent Innovations in Alloy Development

Recent innovations in alloy development highlight significant advancements in ternary alloys, which incorporate three elements to enhance mechanical properties and corrosion resistance beyond traditional binary alloys composed of two elements. Ternary alloys enable precise tuning of microstructures, resulting in improved strength, ductility, and thermal stability essential for aerospace and automotive industries. Research into high-entropy ternary alloys has revealed exceptional performance in extreme environments, outperforming many binary counterparts due to their complex chemistries and phase compositions.

Future Trends in Binary and Ternary Alloy Research

Future trends in binary and ternary alloy research emphasize enhancing material properties through precise compositional control and advanced computational modeling. Innovations in nanostructuring and high-entropy alloys are expanding the application scope, particularly in aerospace, electronics, and renewable energy sectors. Emphasis on sustainability drives development of low-cost, environmentally friendly alloys with improved mechanical strength, corrosion resistance, and thermal stability.

Ternary alloy vs Binary alloy Infographic

electrown.com

electrown.com