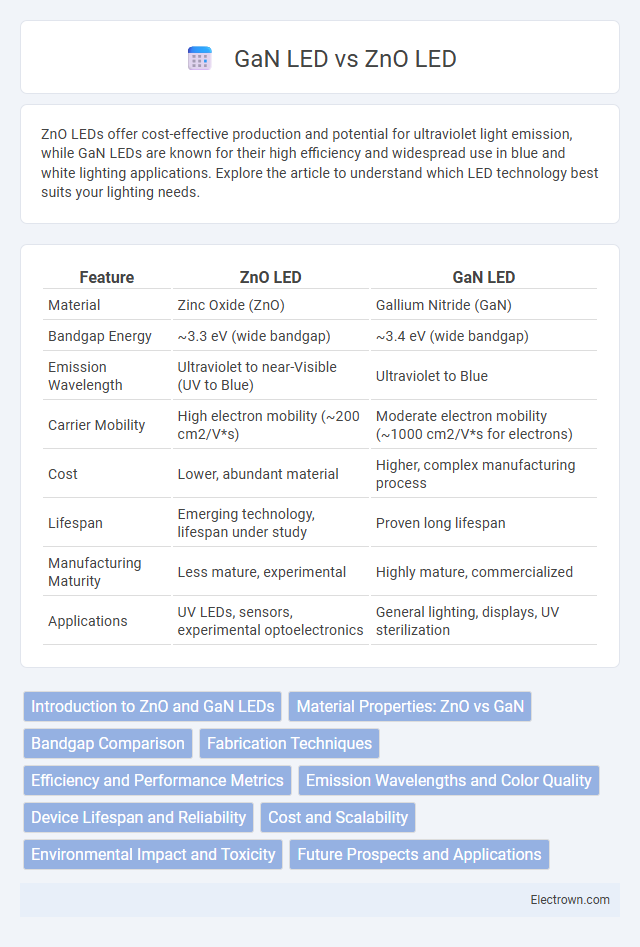

ZnO LEDs offer cost-effective production and potential for ultraviolet light emission, while GaN LEDs are known for their high efficiency and widespread use in blue and white lighting applications. Explore the article to understand which LED technology best suits your lighting needs.

Table of Comparison

| Feature | ZnO LED | GaN LED |

|---|---|---|

| Material | Zinc Oxide (ZnO) | Gallium Nitride (GaN) |

| Bandgap Energy | ~3.3 eV (wide bandgap) | ~3.4 eV (wide bandgap) |

| Emission Wavelength | Ultraviolet to near-Visible (UV to Blue) | Ultraviolet to Blue |

| Carrier Mobility | High electron mobility (~200 cm2/V*s) | Moderate electron mobility (~1000 cm2/V*s for electrons) |

| Cost | Lower, abundant material | Higher, complex manufacturing process |

| Lifespan | Emerging technology, lifespan under study | Proven long lifespan |

| Manufacturing Maturity | Less mature, experimental | Highly mature, commercialized |

| Applications | UV LEDs, sensors, experimental optoelectronics | General lighting, displays, UV sterilization |

Introduction to ZnO and GaN LEDs

ZnO LEDs utilize zinc oxide as the semiconductor material, known for its wide bandgap of approximately 3.37 eV and high exciton binding energy, which enables efficient ultraviolet to visible light emission. GaN LEDs, based on gallium nitride with a similar wide bandgap around 3.4 eV, dominate the LED market due to their high efficiency and stability in blue and UV light applications. Your choice between ZnO and GaN LEDs depends on factors like emission wavelength, material availability, and device performance requirements in optoelectronic applications.

Material Properties: ZnO vs GaN

Zinc oxide (ZnO) LEDs offer a direct wide bandgap of approximately 3.37 eV with high exciton binding energy around 60 meV, enabling efficient ultraviolet and visible light emission at room temperature. Gallium nitride (GaN) LEDs feature a slightly wider bandgap near 3.4 eV and superior thermal stability, which contributes to higher reliability and performance under high-power conditions. ZnO's abundant availability and easier doping contrast with GaN's mature fabrication technology and established commercial use in blue and white LEDs.

Bandgap Comparison

ZnO LEDs possess a direct bandgap of approximately 3.37 eV, which is slightly wider than GaN LEDs, featuring a bandgap around 3.4 eV. This bandgap difference influences the emission wavelength, with ZnO typically emitting in the ultraviolet to near-UV range, while GaN covers a broader spectrum from UV to blue light. Understanding the bandgap comparison helps optimize your choice for applications requiring specific emission properties and device efficiency.

Fabrication Techniques

ZnO LEDs often utilize pulsed laser deposition (PLD) or hydrothermal methods for film growth due to ZnO's availability in single crystals and the need for low-temperature processes. GaN LEDs commonly rely on metal-organic chemical vapor deposition (MOCVD) or molecular beam epitaxy (MBE) to achieve high crystalline quality essential for efficient light emission. The fabrication complexity of GaN LEDs is higher because of lattice mismatch and substrate requirements, whereas ZnO LEDs benefit from easier integration on diverse substrates but face challenges in p-type doping control.

Efficiency and Performance Metrics

ZnO LEDs typically exhibit lower efficiency and electroluminescence intensity compared to GaN LEDs, primarily due to challenges in achieving high-quality p-type doping and stable defect levels. GaN LEDs dominate the market with superior external quantum efficiencies often exceeding 50%, improved thermal stability, and longer operational lifetimes, making them ideal for high-performance lighting and display applications. Understanding these performance metrics helps you select the optimal LED material based on efficiency demands and application-specific requirements.

Emission Wavelengths and Color Quality

ZnO LEDs typically emit ultraviolet to visible light in the range of 380-450 nm, offering sharp emission peaks and high color purity, which is ideal for applications requiring precise color rendering. GaN LEDs cover a broader spectrum from near-ultraviolet to blue and green wavelengths around 365-530 nm, known for their high luminous efficiency and vibrant color quality. Your choice between ZnO and GaN LEDs should consider the desired emission wavelength and color quality for optimal performance in lighting or display technology.

Device Lifespan and Reliability

ZnO LEDs generally exhibit shorter device lifespan compared to GaN LEDs due to their susceptibility to oxygen vacancies and surface defects, which degrade performance over time. GaN LEDs have demonstrated superior reliability and longer operational lifetimes, often exceeding tens of thousands of hours, attributed to their robust crystal structure and high thermal stability. Advances in GaN-based materials and fabrication techniques continue to enhance device durability, making them the preferred choice for commercial and industrial lighting applications.

Cost and Scalability

ZnO LEDs generally offer lower material costs and simpler fabrication processes compared to GaN LEDs, making them more cost-effective for large-scale production. GaN LEDs require more sophisticated and expensive manufacturing equipment due to high-temperature growth and substrate processing, which limits scalability and drives up expenses. The scalability of ZnO LEDs benefits from abundant zinc resources and the compatibility with low-cost substrates, positioning them as a promising option for cost-sensitive applications.

Environmental Impact and Toxicity

ZnO LEDs exhibit lower environmental impact due to their abundance and non-toxic nature, making them safer for large-scale production and disposal compared to GaN LEDs. GaN LEDs, while offering higher efficiency, rely on rare earth elements and toxic chemicals during manufacturing that raise concerns over resource depletion and hazardous waste. Sustainable development favors ZnO LEDs for eco-friendly optoelectronic devices with reduced ecological footprint and minimal toxicity risks.

Future Prospects and Applications

ZnO LEDs exhibit strong potential for ultraviolet light applications due to their wide bandgap and high exciton binding energy, making them ideal for sterilization and biomedical devices. GaN LEDs dominate visible and near-UV markets with mature technology and high efficiency across lighting and display sectors, but face limitations in deep-UV emission efficiency. Future advancements in ZnO LED fabrication and defect control may enable cost-effective UV-C sources, while GaN LED innovations continue to enhance performance in general lighting and high-power electronics.

ZnO LED vs GaN LED Infographic

electrown.com

electrown.com