InGaN and AlGaInP are prominent semiconductor materials used in LED technology, with InGaN excelling in blue and green light emission due to its wide bandgap and high efficiency, while AlGaInP is favored for red and amber LEDs because of its superior wavelength tunability and brightness. Understanding the differences in their properties and applications can help you choose the right material for specific lighting needs--explore the rest of the article for an in-depth comparison.

Table of Comparison

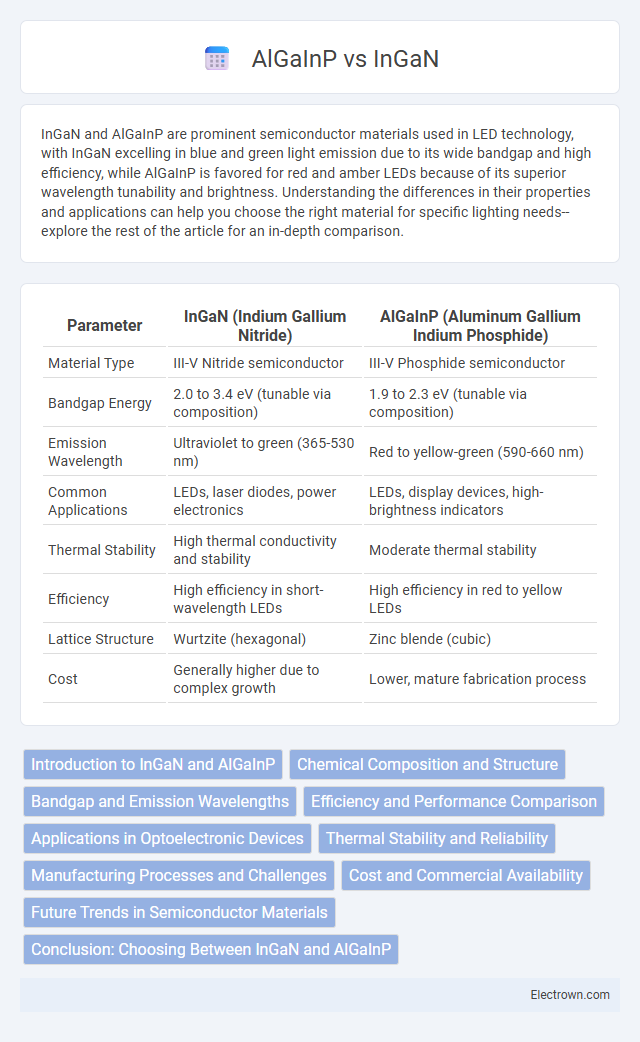

| Parameter | InGaN (Indium Gallium Nitride) | AlGaInP (Aluminum Gallium Indium Phosphide) |

|---|---|---|

| Material Type | III-V Nitride semiconductor | III-V Phosphide semiconductor |

| Bandgap Energy | 2.0 to 3.4 eV (tunable via composition) | 1.9 to 2.3 eV (tunable via composition) |

| Emission Wavelength | Ultraviolet to green (365-530 nm) | Red to yellow-green (590-660 nm) |

| Common Applications | LEDs, laser diodes, power electronics | LEDs, display devices, high-brightness indicators |

| Thermal Stability | High thermal conductivity and stability | Moderate thermal stability |

| Efficiency | High efficiency in short-wavelength LEDs | High efficiency in red to yellow LEDs |

| Lattice Structure | Wurtzite (hexagonal) | Zinc blende (cubic) |

| Cost | Generally higher due to complex growth | Lower, mature fabrication process |

Introduction to InGaN and AlGaInP

InGaN (Indium Gallium Nitride) and AlGaInP (Aluminum Gallium Indium Phosphide) are semiconductor materials widely used in LED technology. InGaN is known for its efficiency in producing blue and green light, while AlGaInP is primarily utilized for red, orange, and yellow LEDs due to its direct bandgap properties. Both materials play crucial roles in full-spectrum LED applications, leveraging their distinct bandgap energies for optimized color emission.

Chemical Composition and Structure

InGaN consists of indium, gallium, and nitrogen atoms forming a wurtzite crystal structure, which is critical for its direct bandgap and high electron mobility. AlGaInP, on the other hand, is composed of aluminum, gallium, indium, and phosphorus, exhibiting a zinc blende crystal lattice that contributes to its tunable bandgap properties. Understanding the differences in chemical composition and crystalline structure helps optimize Your choice for applications in LEDs and optoelectronic devices.

Bandgap and Emission Wavelengths

InGaN (Indium Gallium Nitride) exhibits a tunable direct bandgap ranging from about 0.7 eV to 3.4 eV, enabling efficient emission across the visible spectrum from near-infrared to ultraviolet, particularly in blue and green LEDs. AlGaInP (Aluminum Gallium Indium Phosphide) has a direct bandgap typically between 1.9 eV and 2.3 eV, optimized for red to yellow light emission, making it ideal for red, orange, and yellow LEDs. The wider bandgap variability in InGaN allows broader emission wavelength control compared to the narrower AlGaInP range, resulting in distinct applications in multi-color LED technologies.

Efficiency and Performance Comparison

InGaN LEDs exhibit higher efficiency and superior performance, especially in blue and green wavelength ranges, due to their wider bandgap and better electron confinement compared to AlGaInP. AlGaInP LEDs are typically more efficient in the red to yellow spectrum but suffer from efficiency droop at high current densities. The material properties of InGaN enable better thermal stability and longer operational lifetimes, making them preferred for high-brightness and high-power applications.

Applications in Optoelectronic Devices

InGaN is widely used in blue and green light-emitting diodes (LEDs) and laser diodes, essential for high-efficiency solid-state lighting and high-density optical data storage. AlGaInP is predominant in red, orange, and yellow LEDs, crucial for full-spectrum display technologies and traffic signal applications. Both materials enable efficient optoelectronic devices by leveraging their tunable bandgap properties for specific wavelength emissions.

Thermal Stability and Reliability

InGaN LEDs exhibit superior thermal stability compared to AlGaInP, maintaining consistent luminous output and efficiency at elevated temperatures due to their wide bandgap properties. AlGaInP devices are more prone to efficiency droop and degradation under thermal stress, impacting long-term reliability. Optimizing your application with InGaN can enhance durability and performance in high-temperature environments.

Manufacturing Processes and Challenges

InGaN LEDs require complex epitaxial growth techniques such as metal-organic chemical vapor deposition (MOCVD) to handle lattice mismatches and manage strain in the crystal structure, which often leads to challenges like defect generation and efficiency droop at high currents. AlGaInP LEDs, by comparison, utilize similar MOCVD processes but face fewer strain-related issues due to better lattice matching with GaAs substrates, enabling more straightforward manufacturing with higher internal quantum efficiency. Your choice between InGaN and AlGaInP depends on balancing the difficulty of controlling indium incorporation and crystal quality in InGaN against the more mature, reliable production processes of AlGaInP for red to yellow wavelengths.

Cost and Commercial Availability

InGaN LEDs typically offer lower production costs due to more mature manufacturing processes and abundant raw materials, making them widely available in commercial markets for applications like blue and green lighting. AlGaInP LEDs, while generally more expensive because of complex epitaxial growth and limited substrate options, are prized for high-efficiency red and amber emissions and have a robust, though slightly less extensive, commercial presence. Your choice between InGaN and AlGaInP will depend on budget constraints and the specific wavelength requirements for your project.

Future Trends in Semiconductor Materials

InGaN semiconductor materials continue to dominate future trends due to their superior efficiency in blue and green LED applications, offering enhanced brightness and energy savings. In contrast, AlGaInP remains pivotal for red and amber LEDs, with ongoing innovations improving its thermal stability and luminous efficacy. Emerging research targets combining these materials with novel nanostructures to optimize performance in next-generation optoelectronic devices.

Conclusion: Choosing Between InGaN and AlGaInP

InGaN and AlGaInP are distinguished by their distinct bandgap energies, with InGaN excelling in blue to green light emission and AlGaInP optimized for red to yellow wavelengths. InGaN LEDs offer higher efficiency and better thermal stability for high-brightness applications, while AlGaInP remains preferred for red and amber devices due to its superior color purity. Selecting between InGaN and AlGaInP depends on the targeted emission wavelength, device efficiency needs, and thermal management considerations in practical applications.

InGaN vs AlGaInP Infographic

electrown.com

electrown.com