CW lasers emit a continuous, stable beam ideal for applications requiring steady energy delivery, while pulsed lasers release energy in short, intense bursts suitable for precision tasks and minimizing thermal damage. Discover how choosing between these laser types can optimize Your specific needs by reading the rest of the article.

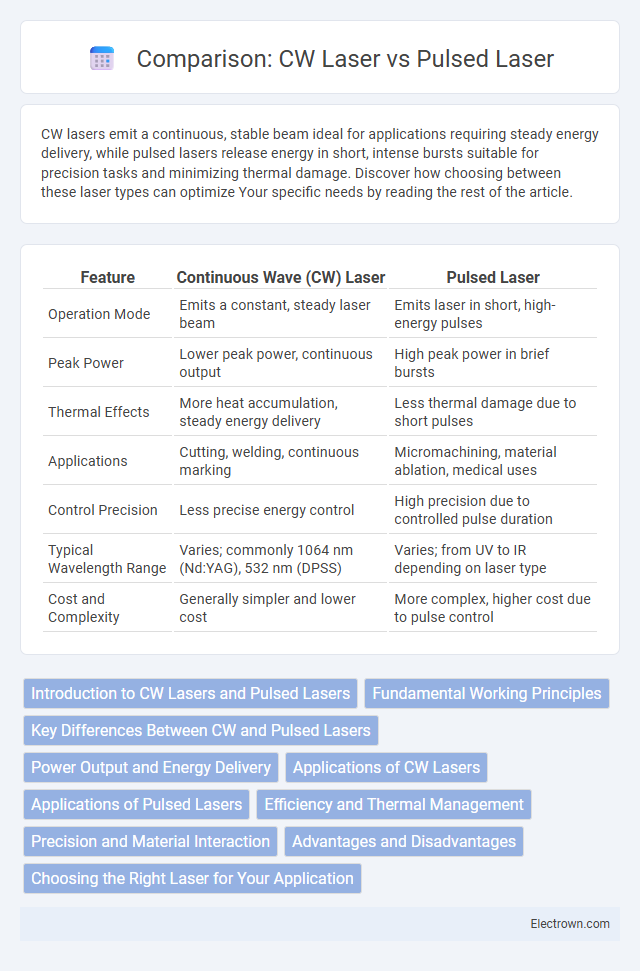

Table of Comparison

| Feature | Continuous Wave (CW) Laser | Pulsed Laser |

|---|---|---|

| Operation Mode | Emits a constant, steady laser beam | Emits laser in short, high-energy pulses |

| Peak Power | Lower peak power, continuous output | High peak power in brief bursts |

| Thermal Effects | More heat accumulation, steady energy delivery | Less thermal damage due to short pulses |

| Applications | Cutting, welding, continuous marking | Micromachining, material ablation, medical uses |

| Control Precision | Less precise energy control | High precision due to controlled pulse duration |

| Typical Wavelength Range | Varies; commonly 1064 nm (Nd:YAG), 532 nm (DPSS) | Varies; from UV to IR depending on laser type |

| Cost and Complexity | Generally simpler and lower cost | More complex, higher cost due to pulse control |

Introduction to CW Lasers and Pulsed Lasers

CW lasers emit a continuous, steady beam of light, making them ideal for applications requiring constant energy delivery such as cutting and welding. Pulsed lasers produce light in short, high-energy bursts, enabling precise control in applications like medical procedures and material processing. Each laser type leverages distinct operational modes to optimize performance based on specific industrial or scientific needs.

Fundamental Working Principles

CW lasers emit a continuous, steady beam of light by maintaining a constant electrical current or optical pumping, resulting in uninterrupted photon output. Pulsed lasers generate light in short, high-intensity bursts through rapid modulation of the gain medium or Q-switching techniques, producing pulses with high peak power and controlled duration. The fundamental difference lies in the temporal emission: CW lasers provide continuous energy, while pulsed lasers deliver discrete energy packets, influencing their applications in materials processing, medical procedures, and communications.

Key Differences Between CW and Pulsed Lasers

CW lasers emit a continuous, steady beam of light, providing consistent energy output ideal for applications requiring precision and uniformity. Pulsed lasers release energy in short bursts, enabling high peak power for tasks like cutting or medical procedures where controlled, intense pulses are essential. Your choice depends on whether continuous operation or high-intensity pulses better suit your specific application needs.

Power Output and Energy Delivery

CW lasers provide constant power output, delivering continuous energy ideal for applications requiring steady heat or precise cutting, while pulsed lasers emit energy in short bursts, allowing for higher peak power and controlled energy delivery that minimizes thermal damage. The energy delivery of pulsed lasers can be precisely timed to optimize ablation or material processing, enhancing efficiency in applications like micromachining or medical procedures. CW lasers excel in tasks needing stable energy flow, whereas pulsed lasers offer advantages in managing thermal effects and achieving high-intensity impacts over brief durations.

Applications of CW Lasers

CW lasers provide a continuous, stable beam ideal for applications requiring uniform energy delivery, such as laser cutting, welding, and medical treatments like photocoagulation. Their constant output enables precise control in processes like spectroscopy and optical communication, where signal consistency is crucial. You benefit from CW lasers' reliability in industrial manufacturing and scientific research due to their ability to maintain steady power over extended periods.

Applications of Pulsed Lasers

Pulsed lasers are widely used in precision material processing, including micromachining, medical surgeries, and tattoo removal, due to their ability to deliver high peak power in short bursts, minimizing thermal damage. They are essential in scientific research for time-resolved spectroscopy and fluorescence lifetime imaging, enabling detailed analysis of fast chemical and biological processes. In defense and telecommunications, pulsed lasers facilitate LIDAR systems and optical data transmission by providing controlled, high-intensity pulses.

Efficiency and Thermal Management

CW lasers deliver a continuous output that enables consistent energy delivery, promoting efficient thermal conduction and stable heat dissipation during operation. Pulsed lasers emit energy in short bursts, which can lead to higher peak power but may cause localized thermal spikes, challenging effective thermal management. Optimizing your system requires balancing the continuous efficiency of CW lasers with the targeted energy delivery of pulsed lasers to maintain temperature control and maximize performance.

Precision and Material Interaction

CW lasers provide continuous, stable output that enables high precision in cutting and engraving, ideal for fine detail work and smooth edges. Pulsed lasers deliver energy in short bursts, allowing greater control over heat input and minimizing thermal damage, which is beneficial for materials sensitive to heat or requiring micro-machining. The choice between CW and pulsed laser depends on the application's precision needs and material characteristics, with pulsed lasers often superior for delicate materials due to reduced heat-affected zones.

Advantages and Disadvantages

CW lasers offer continuous, stable output making them ideal for applications requiring steady energy delivery like cutting and welding, but they tend to generate more heat, potentially causing thermal damage to sensitive materials. Pulsed lasers deliver energy in short, high-peak power bursts, minimizing thermal effects and enabling precise material processing, though they often require complex timing control and have lower average power output. The choice between CW and pulsed lasers depends on the specific application requirements, balancing thermal management, precision, and power efficiency.

Choosing the Right Laser for Your Application

Selecting between a CW (continuous wave) laser and a pulsed laser depends on your application's precision, energy delivery, and material interaction needs. CW lasers provide constant power output ideal for applications requiring steady heating or cutting, while pulsed lasers deliver high peak power in short bursts, enhancing control in processes like micromachining or laser ablation. Understanding the specific requirements such as pulse duration, energy density, and thermal effects ensures the right laser optimizes performance and efficiency.

CW laser vs Pulsed laser Infographic

electrown.com

electrown.com