Polarization maintaining fiber preserves the polarization state of light over long distances, making it essential for applications requiring stable polarization such as interferometry and sensors, whereas standard fiber does not provide this control, leading to polarization mode dispersion and instability. Discover how understanding the differences between these fibers can optimize your optical systems by reading the full article.

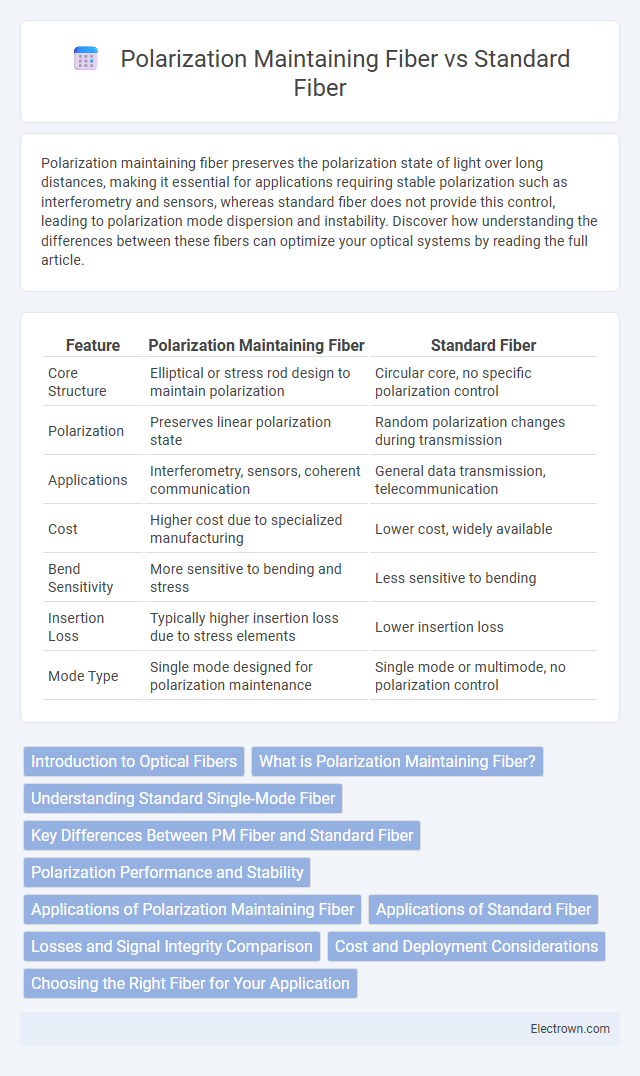

Table of Comparison

| Feature | Polarization Maintaining Fiber | Standard Fiber |

|---|---|---|

| Core Structure | Elliptical or stress rod design to maintain polarization | Circular core, no specific polarization control |

| Polarization | Preserves linear polarization state | Random polarization changes during transmission |

| Applications | Interferometry, sensors, coherent communication | General data transmission, telecommunication |

| Cost | Higher cost due to specialized manufacturing | Lower cost, widely available |

| Bend Sensitivity | More sensitive to bending and stress | Less sensitive to bending |

| Insertion Loss | Typically higher insertion loss due to stress elements | Lower insertion loss |

| Mode Type | Single mode designed for polarization maintenance | Single mode or multimode, no polarization control |

Introduction to Optical Fibers

Polarization maintaining fibers (PMFs) are specialized optical fibers designed to preserve the polarization state of light signals, crucial in applications like fiber optic sensors and coherent communication systems. Standard optical fibers, widely used for general data transmission, do not control polarization, leading to signal degradation in polarization-sensitive applications. The unique internal stress or elliptical core of PMFs minimizes polarization mode dispersion, enhancing signal integrity compared to conventional fibers.

What is Polarization Maintaining Fiber?

Polarization Maintaining Fiber (PMF) is a specialized type of optical fiber designed to preserve the polarization state of light over long distances, ensuring minimal polarization mode dispersion. Unlike standard fiber, which allows polarization states to fluctuate due to environmental factors, PMF contains built-in stress elements that create birefringence, maintaining a stable polarization axis. This makes PMF ideal for applications requiring high precision in polarization-sensitive measurements or coherent optical communications, enhancing the reliability of Your signal transmission.

Understanding Standard Single-Mode Fiber

Standard single-mode fiber guides light with a core diameter of approximately 8-10 microns, allowing only one propagation mode and minimizing signal dispersion over long distances. This type of fiber does not preserve the polarization state of light, which can fluctuate due to external stresses and temperature variations. Understanding these characteristics is essential if your application requires stable polarization, where polarization maintaining fiber might be a better choice.

Key Differences Between PM Fiber and Standard Fiber

Polarization maintaining (PM) fiber is specifically engineered with an asymmetric core and internal stress elements to preserve the polarization state of light over long distances, unlike standard fiber which allows polarization to fluctuate due to external perturbations. PM fiber exhibits higher birefringence, enabling minimal polarization mode dispersion (PMD) and stable polarization, critical for applications such as interferometry and quantum communication. Standard fiber is typically used for general data transmission where polarization control is not as crucial, offering lower cost and easier splicing but lacking the precise polarization control inherent to PM fiber.

Polarization Performance and Stability

Polarization maintaining fiber (PMF) provides superior polarization performance by preserving the state of polarization over long distances, minimizing polarization mode dispersion (PMD) and ensuring stable signal transmission. Standard fiber exhibits higher polarization fluctuations due to environmental stresses and random birefringence, leading to signal degradation in sensitive applications. Your optical system benefits from PMF when consistent polarization stability and reduced polarization-dependent loss are critical for maintaining optimal performance.

Applications of Polarization Maintaining Fiber

Polarization Maintaining Fiber (PMF) is crucial in applications requiring stable polarization states, such as fiber optic sensors, interferometric systems, and quantum communication. Unlike standard fiber, which allows polarization to fluctuate, PMF maintains a fixed polarization axis, ensuring high signal integrity in coherent optical systems and high-precision measurements. Your optical network's performance significantly benefits from PMF in environments where polarization control is essential for minimizing signal distortion and optimizing data transmission quality.

Applications of Standard Fiber

Standard fiber is widely used in telecommunications, data transmission, and broadband networks due to its cost-effectiveness and ease of deployment. It supports various applications including internet connectivity, cable television, and long-haul communication systems, where polarization preservation is not critical. Its versatility makes it ideal for general-purpose optical networking and sensing applications.

Losses and Signal Integrity Comparison

Polarization maintaining fibers exhibit significantly lower signal degradation due to their ability to preserve the polarization state, reducing polarization mode dispersion (PMD) and maintaining higher signal integrity over long distances compared to standard fibers. Standard fibers experience higher losses and increased PMD, which can lead to signal distortion and reduced transmission quality, especially in polarization-sensitive applications. Your optical system benefits from choosing polarization maintaining fibers when minimizing losses and maximizing signal fidelity is critical.

Cost and Deployment Considerations

Polarization maintaining fiber typically incurs higher costs due to its specialized manufacturing process and stringent quality requirements to preserve the polarization state over long distances. Deployment of polarization maintaining fiber demands precise handling and splicing techniques, increasing installation time and labor expenses compared to standard fiber. Standard fiber offers greater cost-effectiveness and ease of deployment, making it suitable for general communications but less ideal for applications requiring polarization stability.

Choosing the Right Fiber for Your Application

Polarization maintaining (PM) fiber preserves the polarization state of light, making it essential for applications requiring high precision, such as interferometry and quantum computing, whereas standard fiber is suitable for general data transmission without strict polarization control. Selecting PM fiber ensures minimal polarization mode dispersion and maintains signal integrity in polarization-sensitive systems, while standard fiber offers cost-effectiveness and ease of installation for most telecommunications and sensor networks. Evaluating application requirements like polarization stability, signal coherence, and budget constraints guides the choice between PM and standard fiber.

Polarization maintaining fiber vs Standard fiber Infographic

electrown.com

electrown.com